Premature-resisting conical roller bearing

A tapered roller bearing and roller technology, which is applied in the direction of roller bearings, bearing components, shafts and bearings, can solve the problems of short life, premature bearing aging, and rapid wear of rolling elements, so as to reduce friction torque and prolong service life. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

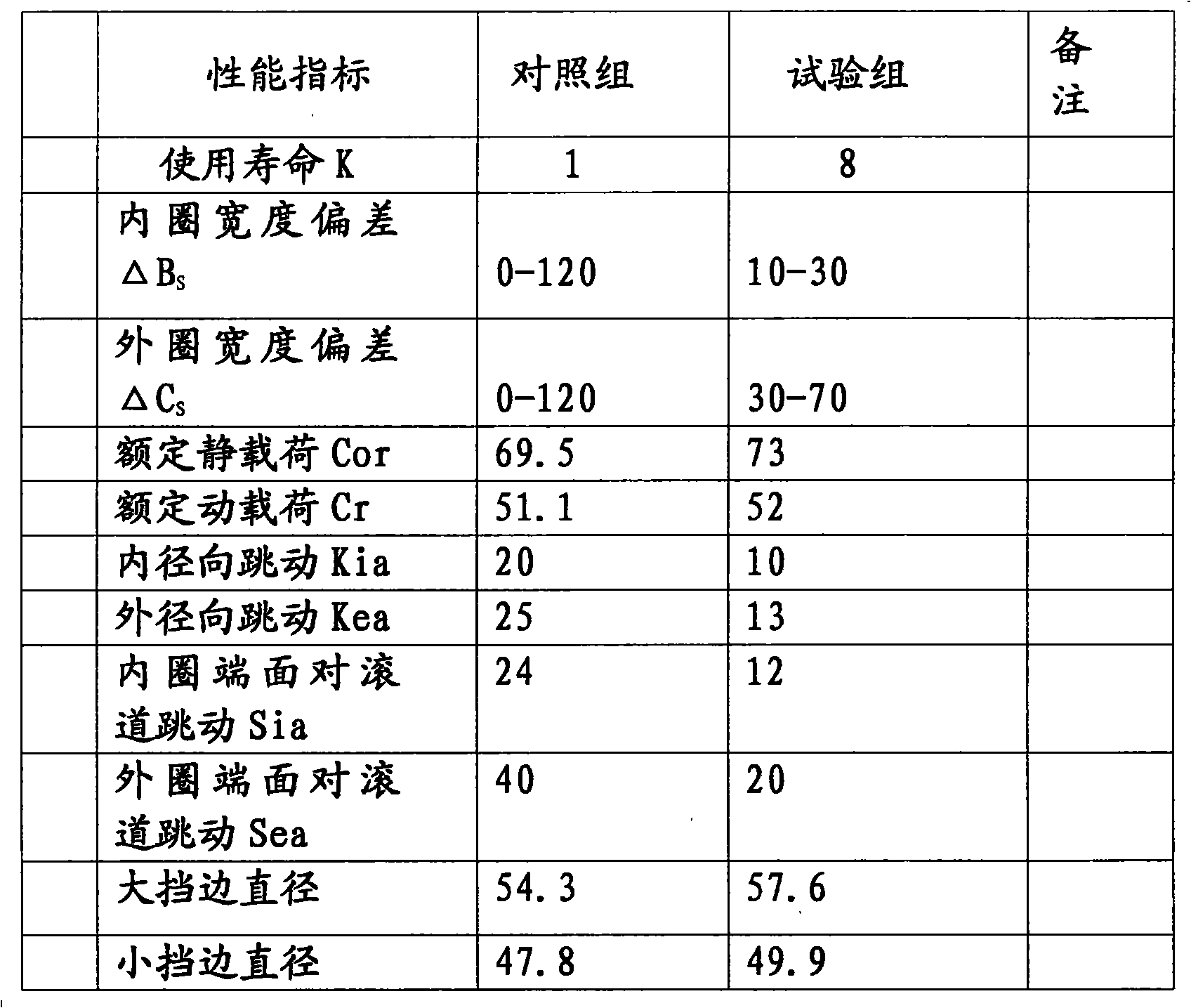

[0009] The anti-premature tapered roller bearing includes inner ring, outer ring, roller and cage. According to the anti-premature design concept, refer to the design scheme of foreign well-known enterprises, and combine the company's actual situation, optimize the rib design and improve its axial bearing capacity; Optimal design of the shape of the oil groove and rolling surface, the roller generatrix adopts an arc curve, the large rib of the inner ring is an arc surface, the shape of the inner raceway and the linearity of the logarithmic correction line of 1.5μm, the shape of the outer raceway and Hyperbola with linearity of 1.5 μm, roller rolling surface shape and arc curve with linearity of 2 μm, inner radial runout of 10, outer radial runout of 11; inner ring width deviation of 20, outer ring width deviation of 50; optimize the manufacturing process and improve its comprehensive load performance; fully consider the elastic deformation, improve the conformity of the raceway...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap