Compact type built-in high-pressure sampling ball valve

A kind of sampling ball, compact technology, applied in the field of design and manufacture of drilling collection equipment, can solve the problems of disappearance, pore water dissolved gas escape, in-situ collection of rock core, etc., and achieve the effect of no leakage collection and broad application prospects

Inactive Publication Date: 2011-05-11

YIBIN SANJIANG MACHINERY

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing marine sediment collection technology mainly uses gravity pistons to collect sediments, and then extracts pore water in the laboratory by means of squeezing, centrifugation and vacuum filtration extraction. However, due to the process from the seabed to the laboratory In the process, the pressure is constantly changing, which will cause the dissolved gas in the pore water to escape or disappear, so the original composition and information of the pore water cannot be accurately reflected, and the in-situ collection of cores cannot be realized.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0006] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

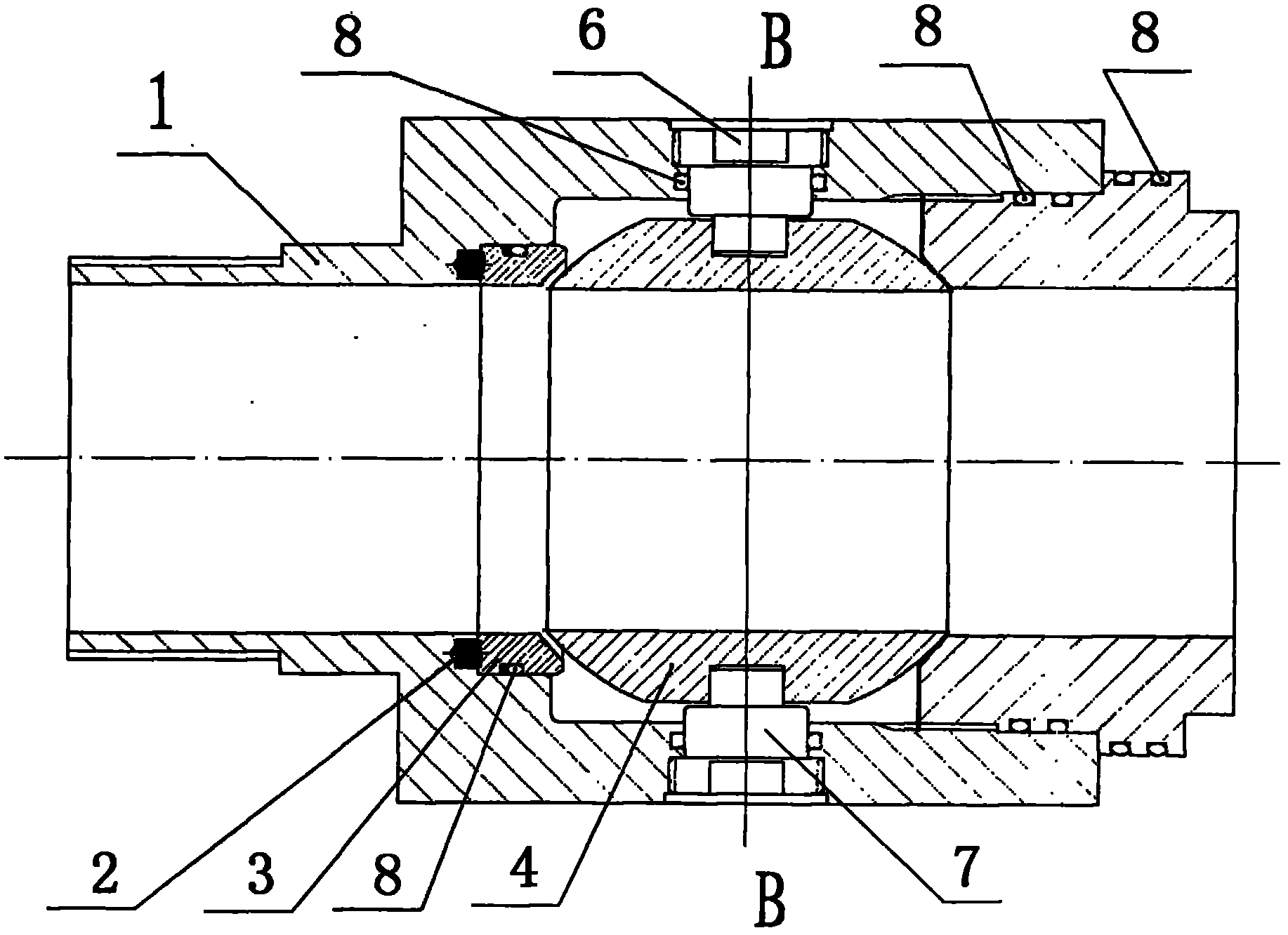

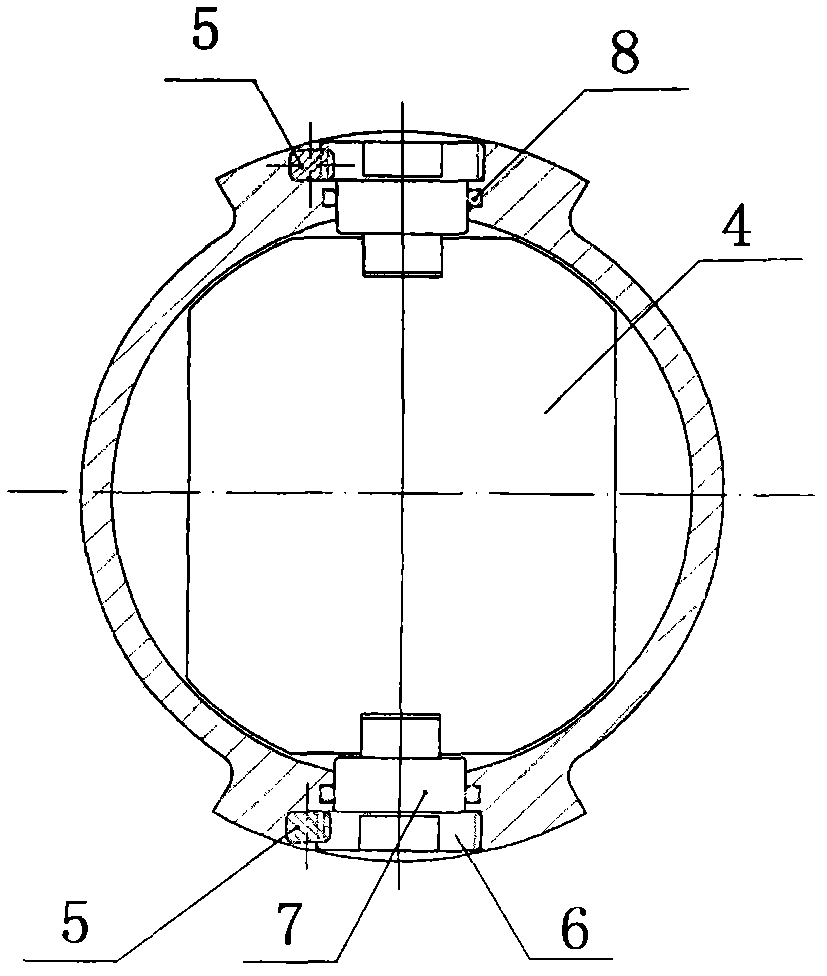

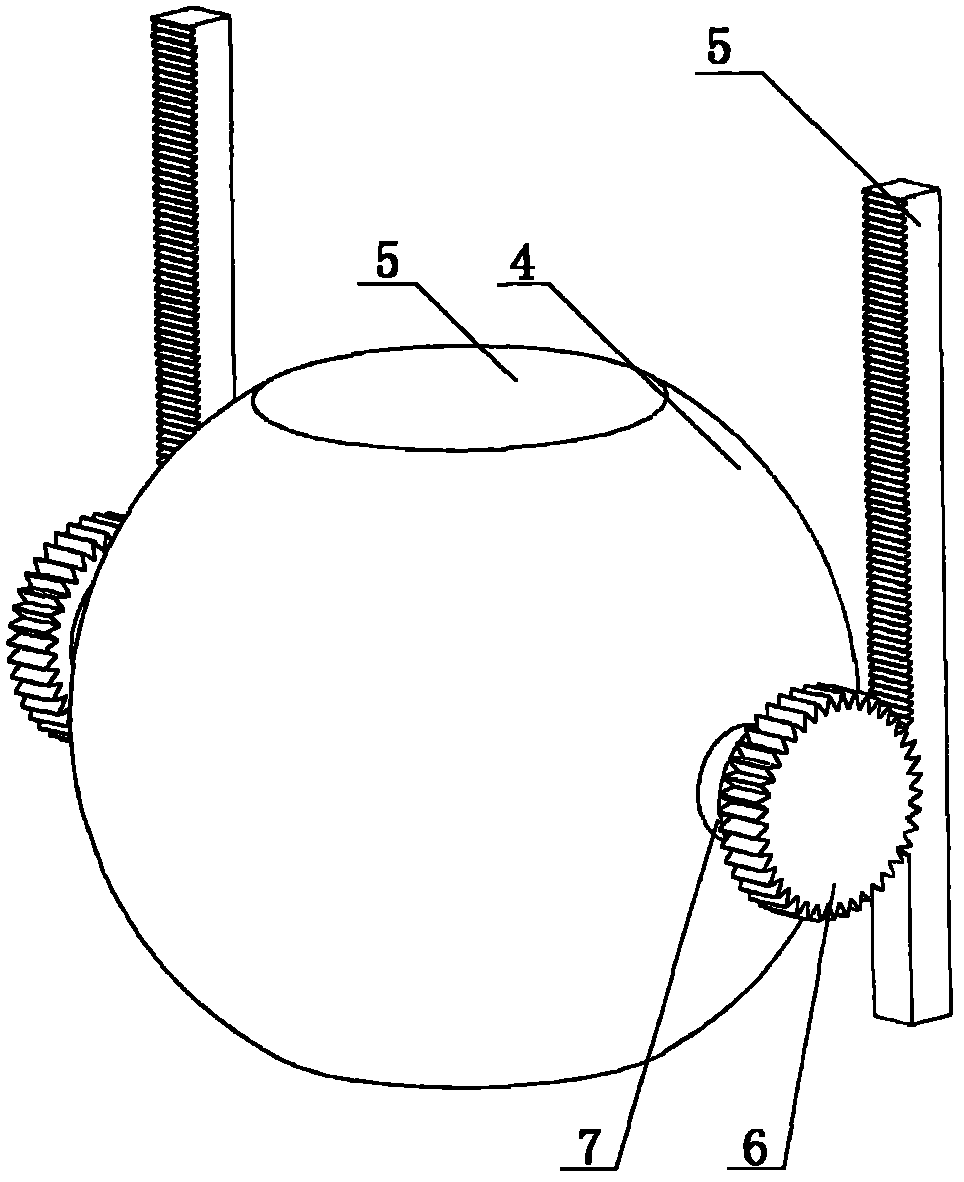

The invention discloses a compact type built-in high-pressure sampling ball valve which is characterized in that a valve body is arranged, a valve seat and a steel ball are arranged in the valve body, and a through hole is formed in the steel ball; a gear shaft is fixedly connected to two ends of the steel ball; and gears on the gear shaft are meshed with racks. The invention has the benefits that the compact type built-in high-pressure ball valve with a special hard sealing structure is designed, so as to guarantee sea bottom in-situ airtight sample core sampling equipment at a depth of 3000 meters under seawater to have an excellent sealing property, sealed operations can be performed during taking samples, non-pollution and leakage-free collection to in-situ airtight sample cores is achieved, and that samples taken from the bottom of the sea keep initial states and information required by a laboratory test is ensured. Therefore, real and satisfying testing results are obtained.

Description

technical field [0001] The invention relates to a ball valve, which is especially suitable for seabed in-situ drilling and sampling equipment, and belongs to the technical field of design and manufacture of drilling and collection devices for seabed natural gas hydrate and marine oil and gas investigation samples. Background technique [0002] The in-situ acquisition and on-site analysis technology of seabed sediments and cores can quickly detect the abnormality and distribution characteristics of CH4, H2S and other gases and Cl-, SO42- plasma in the sample, providing fast and efficient for the exploration of natural gas hydrate and oil and gas resources. geochemical evidence. However, the existing marine sediment collection technology mainly uses gravity pistons to collect sediments, and then extracts pore water in the laboratory by means of squeezing, centrifugation and vacuum filtration extraction. However, due to the process from the seabed to the laboratory In the proc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16K5/06F16K31/54

Inventor 赵宏宇

Owner YIBIN SANJIANG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com