Low-emission environment-friendly boiler

A low-emission, environmentally-friendly technology, applied in steam boilers, furnace-tube steam boilers, steam generation, etc., can solve the problems of slow steam and low utilization rate of heat energy, and achieve the effects of fast output, energy saving and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

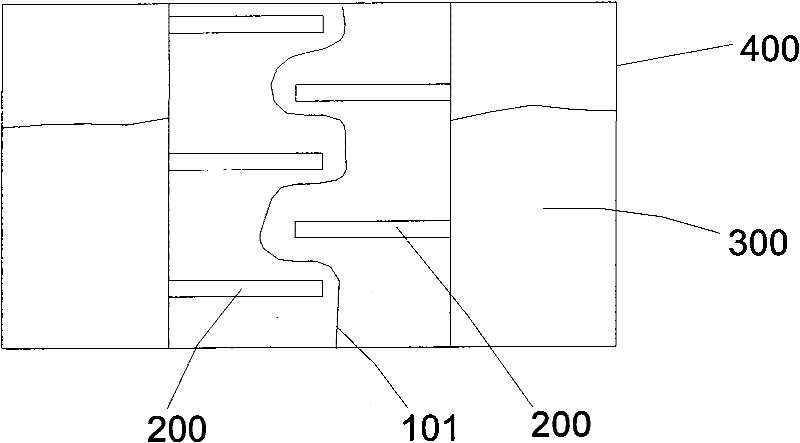

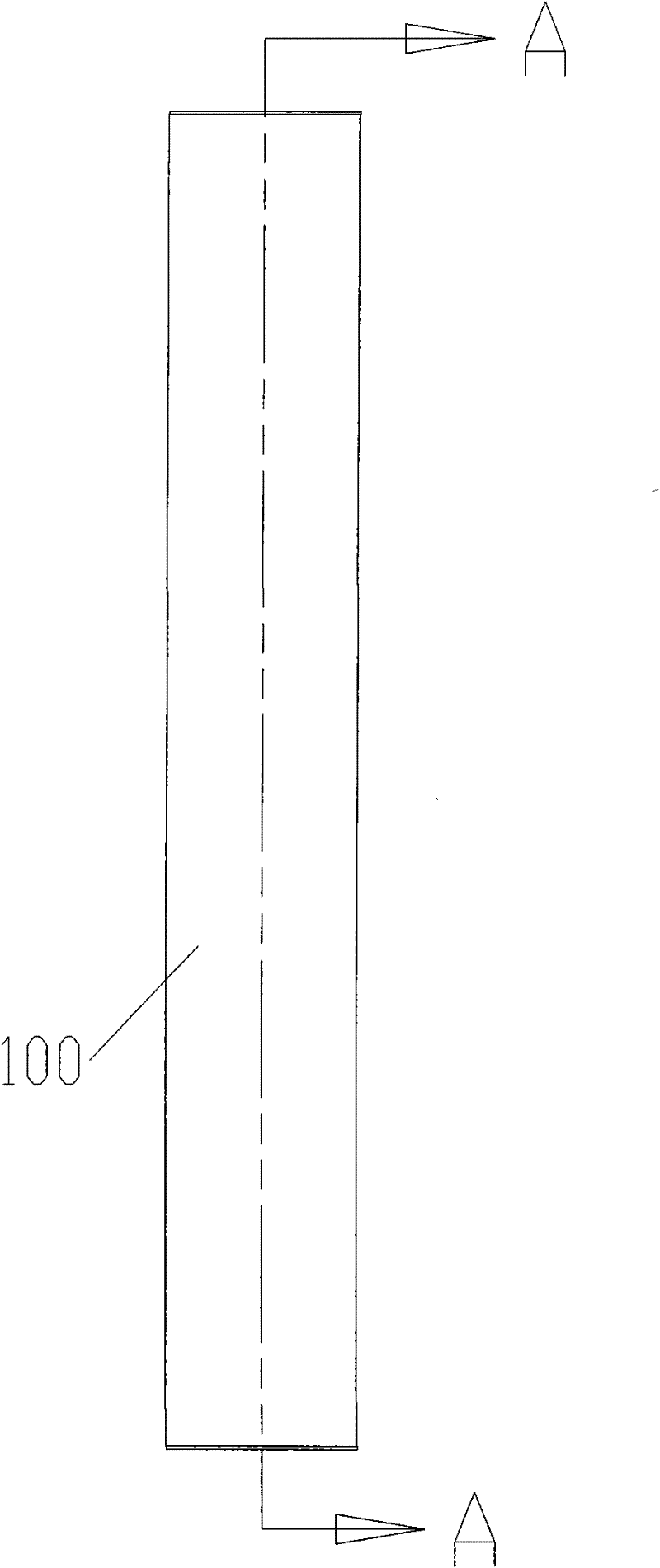

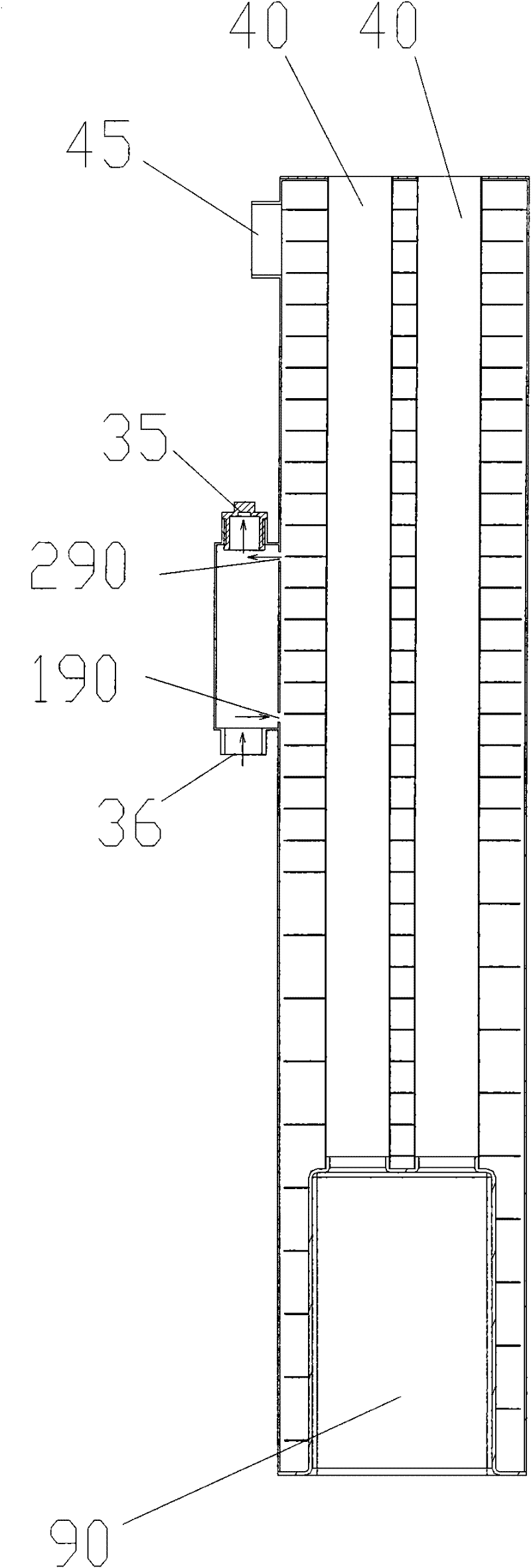

[0027] Such as Figures 2 to 9 The low-emission environmentally friendly boiler according to the first embodiment of the present invention includes a hollow shell provided with water during use, and the low-emission environmentally friendly boiler includes an inwardly sunken combustion access chamber provided at the bottom of the hollow shell 90 and a heat absorbing device arranged in the hollow shell to make water vaporize into water vapor, and the water vapor absorbs heat again and expands multiple times. Wherein, the hollow shell 100 is a cuboid, and six square through holes 40 are provided inside the cuboid, and the height of the square through holes 40 is smaller than the height of the hollow shell 100. In the present invention, there are six fire-stopping and heat-conducting pipes. The square through hole 40 is provided with a combustion access chamber 90 at the bottom of the hollow shell. The function of the combustion access chamber 90 is to allow the flame and flue ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com