System and method for realizing kerosene vapor-phase drying to on-site assembly transformer

An on-site assembly, transformer oil tank technology, applied in transformer/inductor cooling, inductor/transformer/magnet manufacturing, method combination to dry solid materials, etc., can solve problems such as high cost, complex composition, and environmental restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

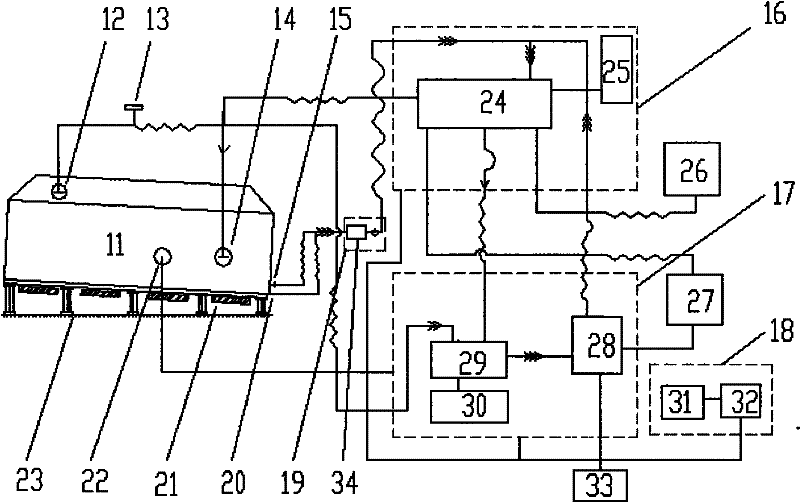

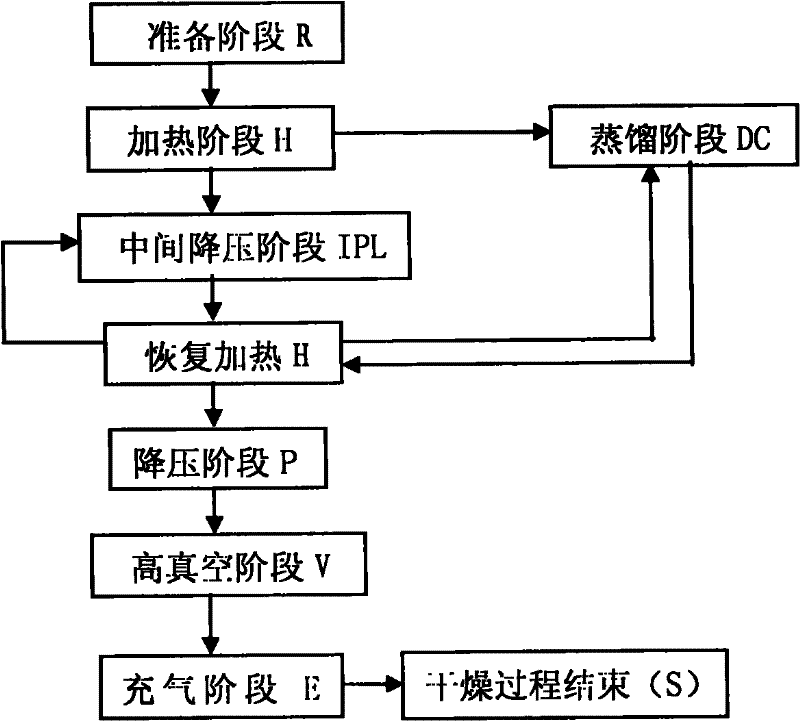

[0051] The content of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0052] In order to solve the problem of how to dry the transformer at the transformer assembly site, and solve the problems of complex composition, high cost and environmental restrictions of the fixed gas-phase drying treatment system, the present invention provides a field-assembled transformer to realize kerosene gas-phase drying The system and method of the present invention can carry out gas-phase drying treatment on transformers at the transformer installation site without being restricted by the environment.

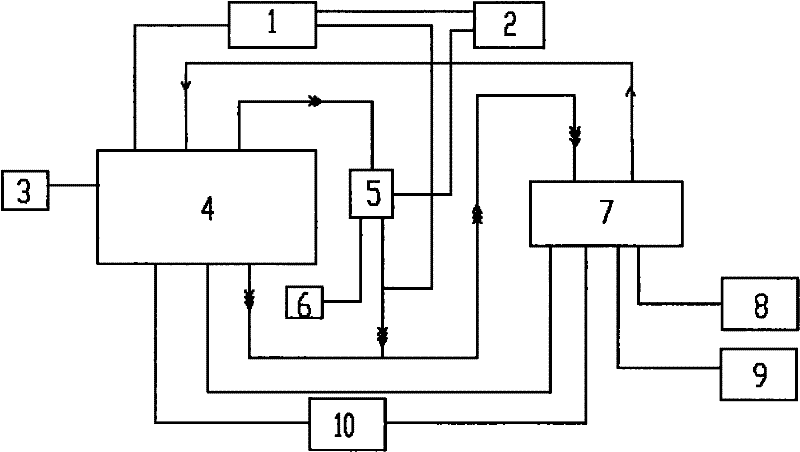

[0053] In order to achieve the purpose of the present invention, the present invention replaces the vacuum tank in the fixed gas-phase drying system with the transformer oil tank containing the transformer, and makes the gas-phase drying treatment equipment modular, and then after the transformer arrives, the system Each component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com