A connector for a gravity feed spray gun, a gravity feed spray gun and a method of preparing a spray paint

A technology of connectors and spray guns, applied in the direction of a single handheld device, mechanical equipment, spraying device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

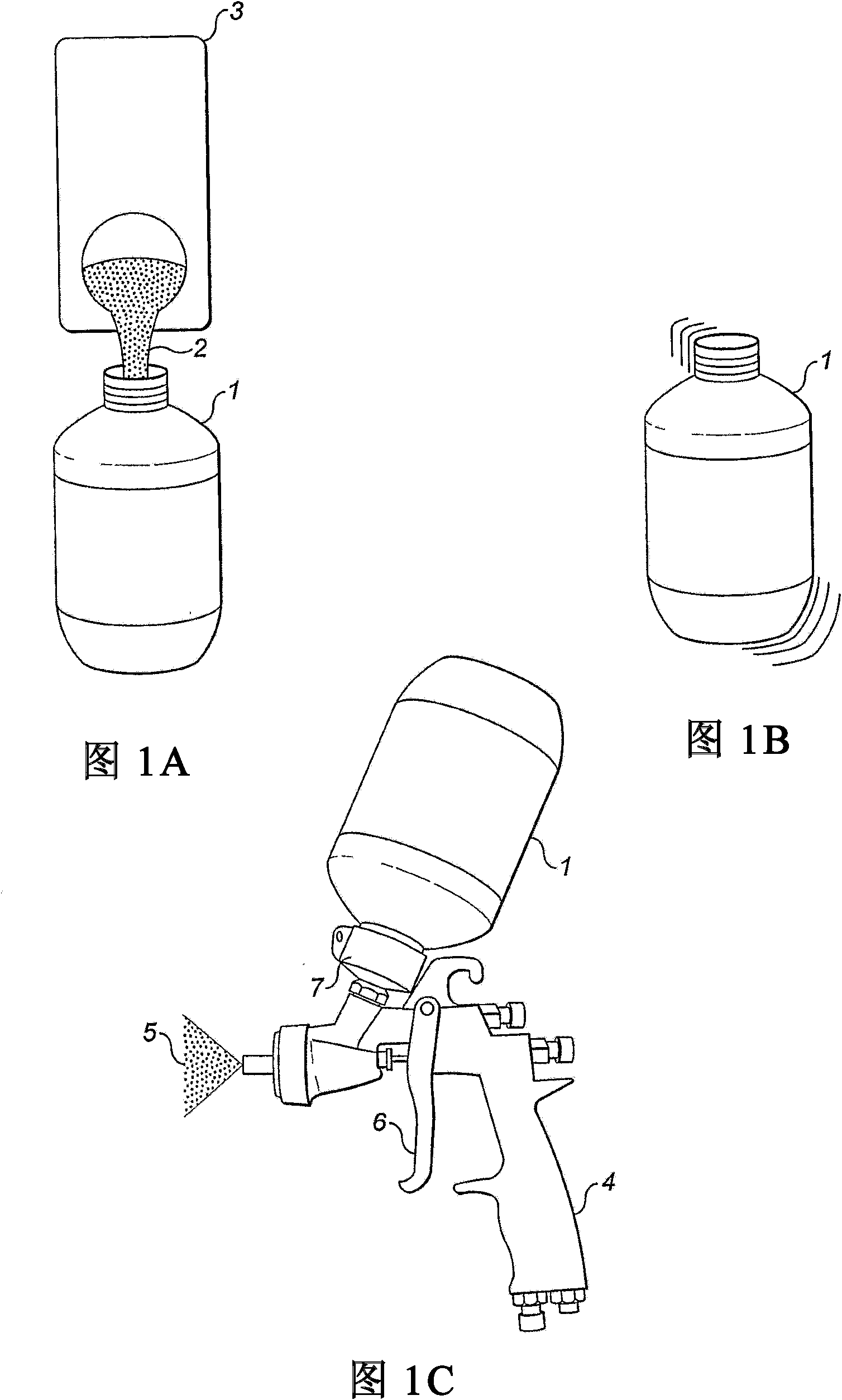

[0039] Figure 1A to Figure 1C A painting system according to one embodiment of the present invention is shown which overcomes the problems associated with painting as described above. First refer to Figure 1A , the container 1 itself is a standard or approximately standard finished container having a threaded opening which can be closed by a standard or approximately standard threaded closure. In this system, container 1 provides the desired amount of a first paint composition already contained therein, which may contain one or more of solvents, pigments, additives, or hardeners. In order to prepare the paint for use, this first paint component must be mixed with a second paint component 2 stored in a separate container 3 . To ensure that the correct amounts of paint components are mixed, a fill line is provided at a predetermined height on the container 1 so that when the user fills the container with a second paint component up to the fill line, the correct proportions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com