Curable compositions

一种固化性组合物、固化促进剂的技术,应用在粘合剂类型、黏合剂添加剂、酯共聚物粘合剂等方向,能够解决低应力性、固化难以充分进行、物性不充分等问题,达到耐冲击粘合强度高、热冲击性良好、残留应力低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

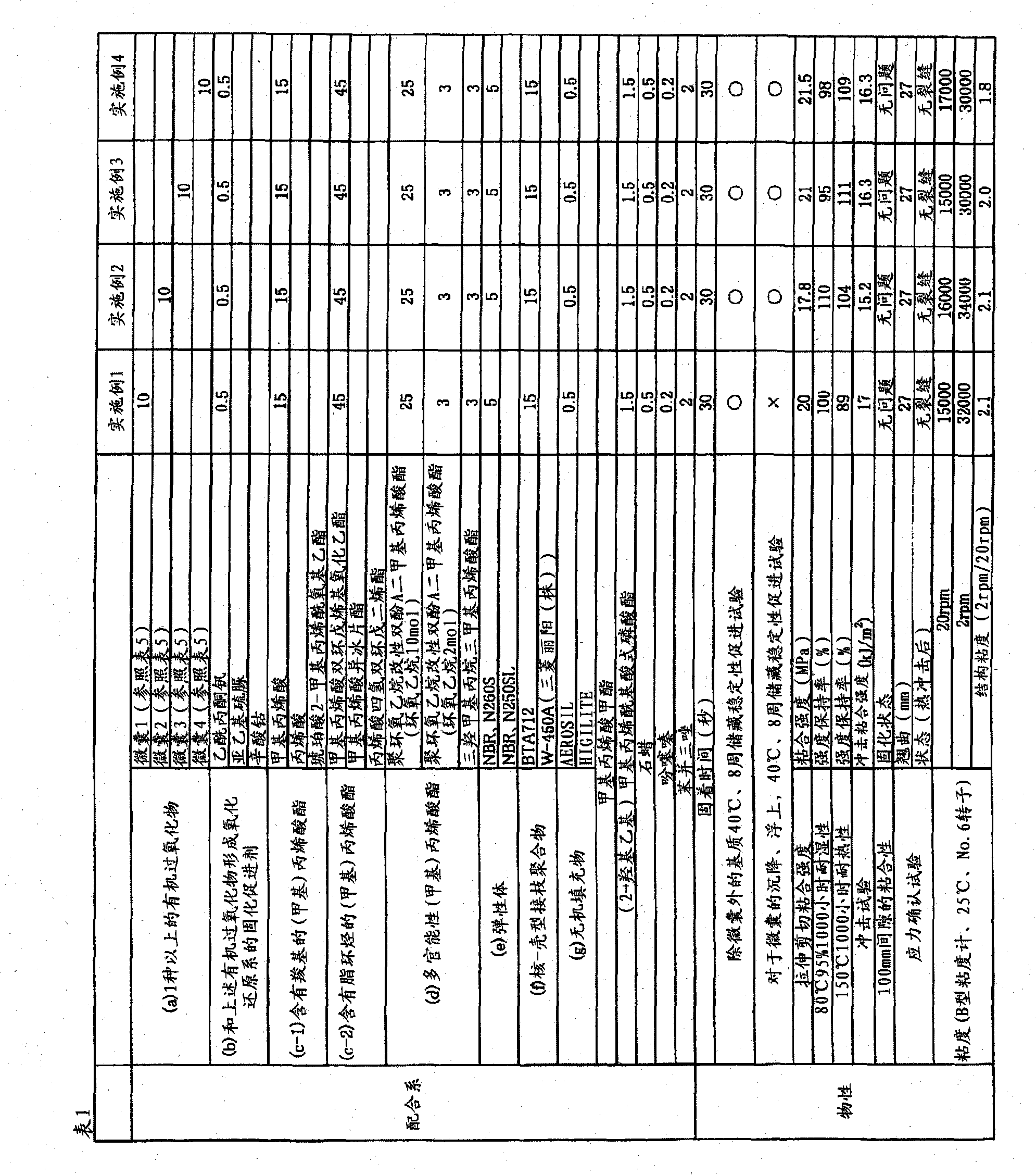

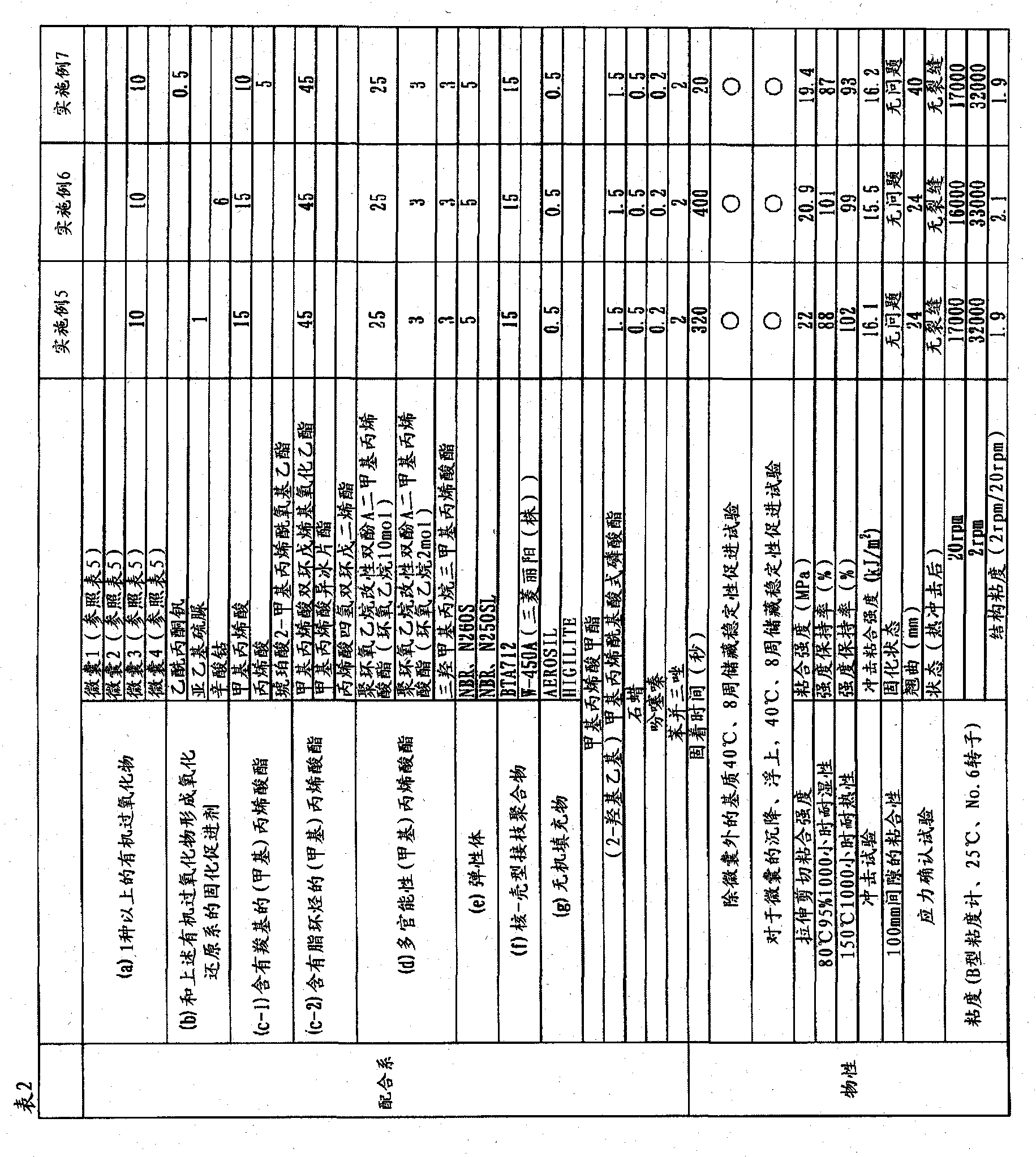

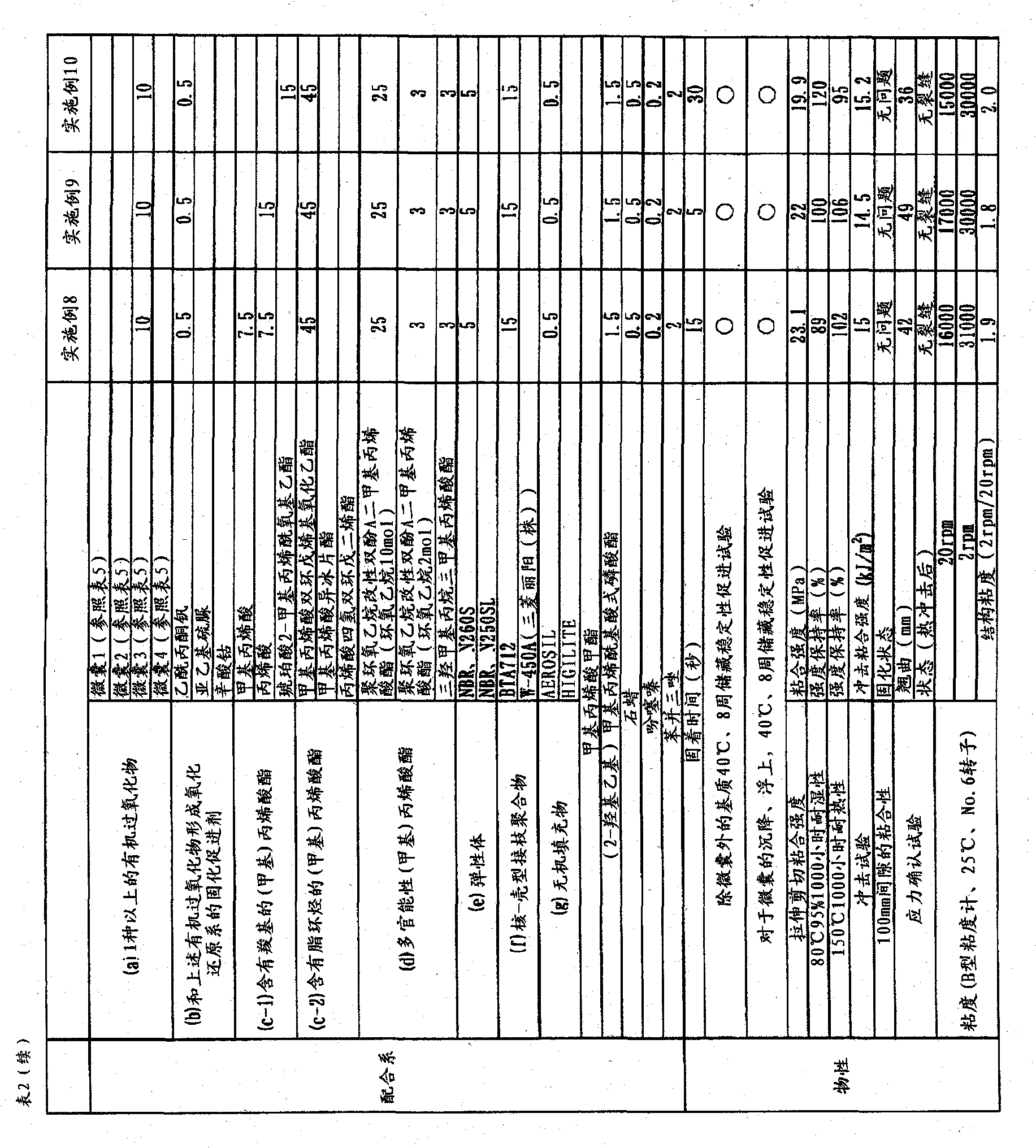

[0100] The curable composition of Example 1, when the total amount of the compounded substances is 126.2 parts by mass, is respectively: Microcapsules [gelatin film 15% by mass, Percumyl H80 (manufactured by NOF Corporation, cumene hydroperoxide 80 %) 30% by mass, tricresyl phosphate (manufactured by Daihachi Chemical Industry Co., Ltd.) 55% by mass, particle diameter of 180 μm or more, average particle diameter of 300 μm] 10 parts by mass, vanadium acetylacetonate (manufactured by Shinshin Chemical Co.) 0.5 parts by mass, formazan Acrylic acid (manufactured by Mitsubishi Gas Chemical Co., Ltd.) 15 parts by mass, dicyclopentenyl oxide ethyl methacrylate (manufactured by Rohm & Haas, QM-657) 45 parts by mass, polyethylene oxide (10 mol) modified bisphenol A Dimethacrylate (manufactured by Shin-Nakamura Chemical Co., Ltd., BPE500) 25 parts by mass, NBR (manufactured by JSR Corporation, N260S) 5 parts by mass, MBS (manufactured by Kureha Chemical Industry Co., Ltd., BTA712) 15 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com