Anti-slip anti-locking centrifugal juicer

An anti-seize and anti-slip technology, which is used in household machinery, household appliances, applications, etc. for filtering food, can solve the problems of large juice residue fragments, large residue fragments, and stuck, achieve good work effect, and solve the problem of skidding. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

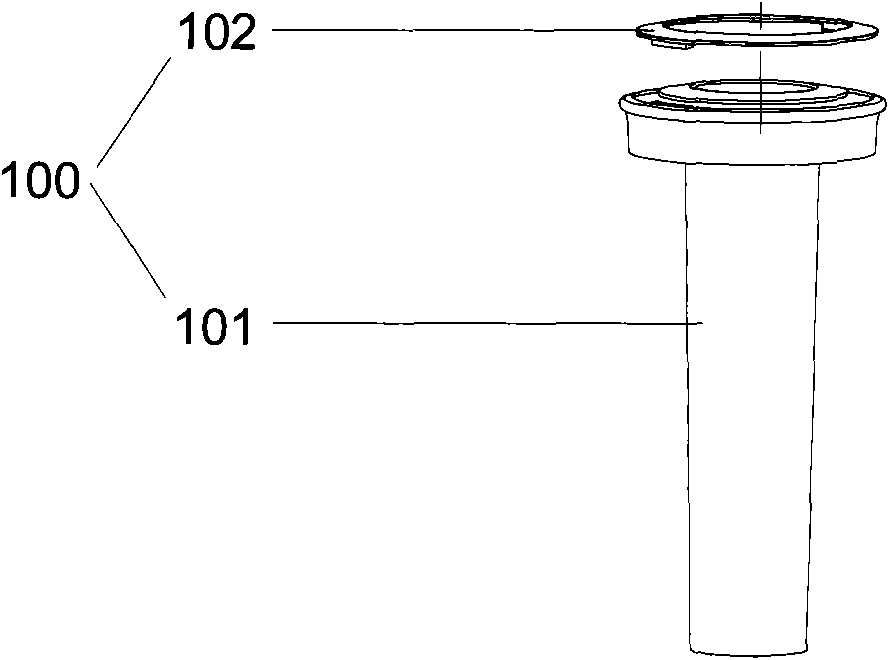

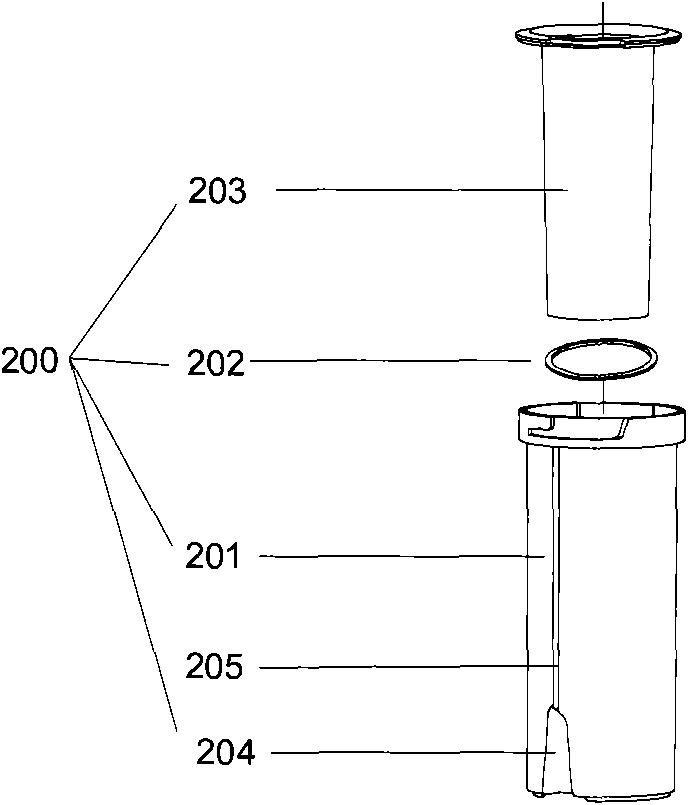

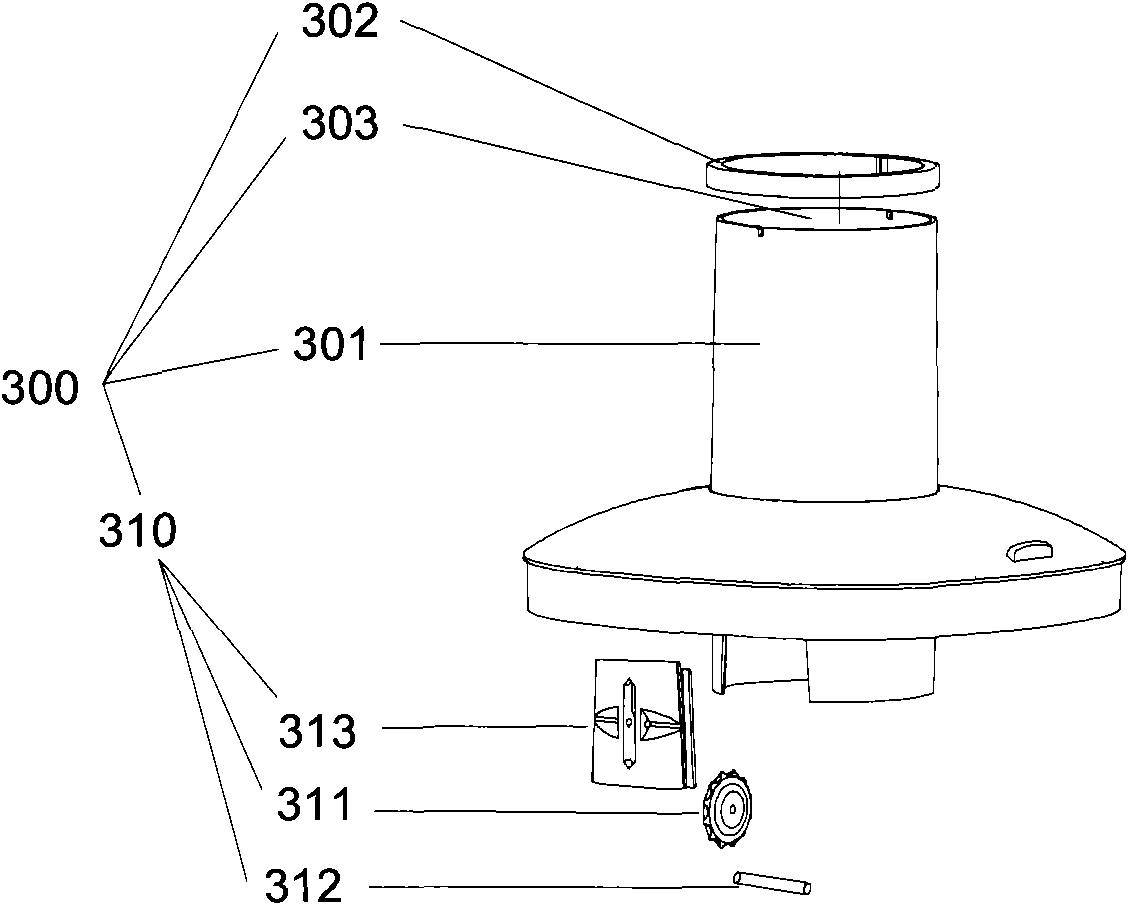

[0030] like Figure 1 to Figure 8 As shown, the anti-slip and anti-seize centrifugal juice extractor of the present invention includes a motor base assembly 800 , and a slag loading tray assembly 600 is installed on the motor assembly 800 . A motor is arranged in the motor base assembly 800, and a through hole is left in the middle of the slag loading pan assembly 600 to allow the drive shaft of the motor to pass through. The cutter head assembly 400 is installed on the top of the slag loading tray assembly 600 and is fixedly connected with the motor transmission shaft through the lower connector assembly 500 . The top cover assembly 300 is sleeved on the cutter head assembly 400 and the slag loading tray assembly 600 . A slicing wheel assembly 310 is provided at a position opposite to the cutter head assembly 400 at the bottom of the top cover assembly 300 . One end of the safety lock assembly 700 is connected to the motor base assembly 800, and can rotate up and down; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com