Henna natural plant hair dye

A hair dye and hair technology, applied in hair care, cosmetics, cosmetic preparations, etc., can solve problems such as long time, single color, heating, etc., and achieve the effect of reducing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

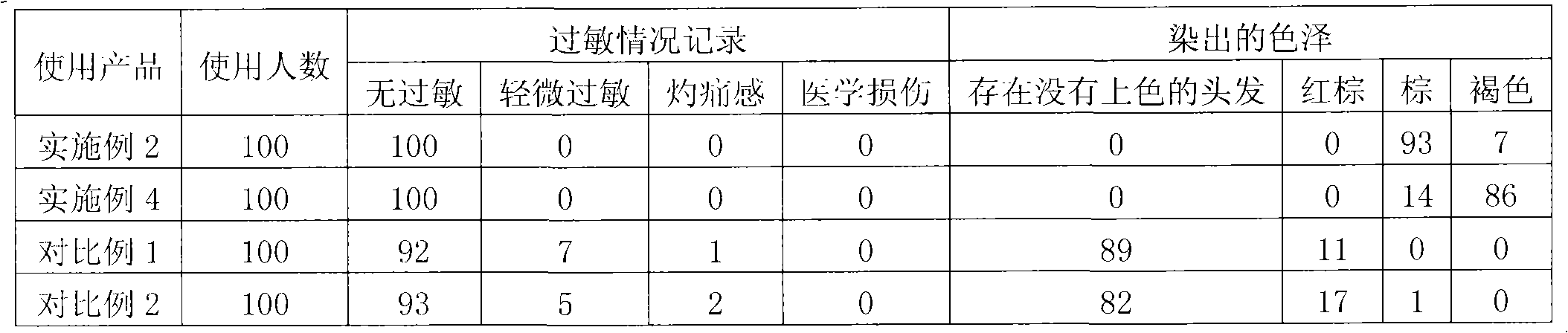

Examples

Embodiment 1

[0057] hair dye

[0058] Henna Ground Powder 15g

[0060] Sodium Carboxymethyl Cellulose 5g

[0061] Get henna ground powder, ferrous sulfate, sodium carboxymethyl cellulose and add into 44g deionized water, fully stir and mix evenly, obtain the hair dye of the present invention.

[0062] Wash the collected white hair, group it, apply the hair dye evenly on the hair and keep it for 1-2.5 hours, then wash the hair. The hair colors dyed are brown (1 hour), brown (1.5 hours), purple-brown (2 hours), and purple-black (2.5 hours).

Embodiment 2

[0064] Hair dye:

[0065] Henna Extract 10g

[0067] Sodium Carboxymethyl Cellulose 10g

[0068] Take henna extract, ferrous chloride, and sodium carboxymethylcellulose and add them to 40 g of water, stir and mix well to obtain the hair dye of the present invention.

[0069] Wash the collected white hair, group it, dry it, apply the hair dye evenly on the hair and keep it for 1-2.5 hours, then wash the hair. The hair colors dyed are brown (1 hour), brown (1.5 hours), purple-brown (2 hours), and purple-black (2.5 hours).

Embodiment 3

[0071] Hair dye:

[0072] Henna Ground Powder 24g

[0074] Clove Extract 2g

[0075] Gelatin 10g

[0076] Softener:

[0077] Cysteine 15g

[0078] Ethylenediamine 10g

[0079] Hydroxyethylcellulose 3g

[0080] Add cysteine, ethylenediamine, and hydroxyethyl cellulose into 40 g of water and stir until completely dissolved and uniform to obtain the treatment agent of the present invention.

[0081] Get henna ground powder, ferrous sulfate, clove extract, gelatin and add into 90g of water, fully stir and mix evenly, obtain the hair dye of the present invention.

[0082] Wash the hair, dry it, apply the softening treatment agent evenly on the hair, and keep it for 15 minutes; then wash the hair, apply the hair dye evenly on the hair, keep it for 40 minutes-2.5 hours, and then wash the hair. The dyed hair colors were brown (40 minutes), brown (1 hour), purple-brown (1.5 hours), purple-black (2 hours), black (2.5 hours).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com