Method and device for separating gas from liquid

A technology of gas-liquid separation and separator, which is applied in separation methods, combined devices, and separation of dispersed particles, etc. It can solve the problems of non-compliance with safety requirements and lack of steam, so as to save steam consumption and prevent landfill gas from being discharged. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

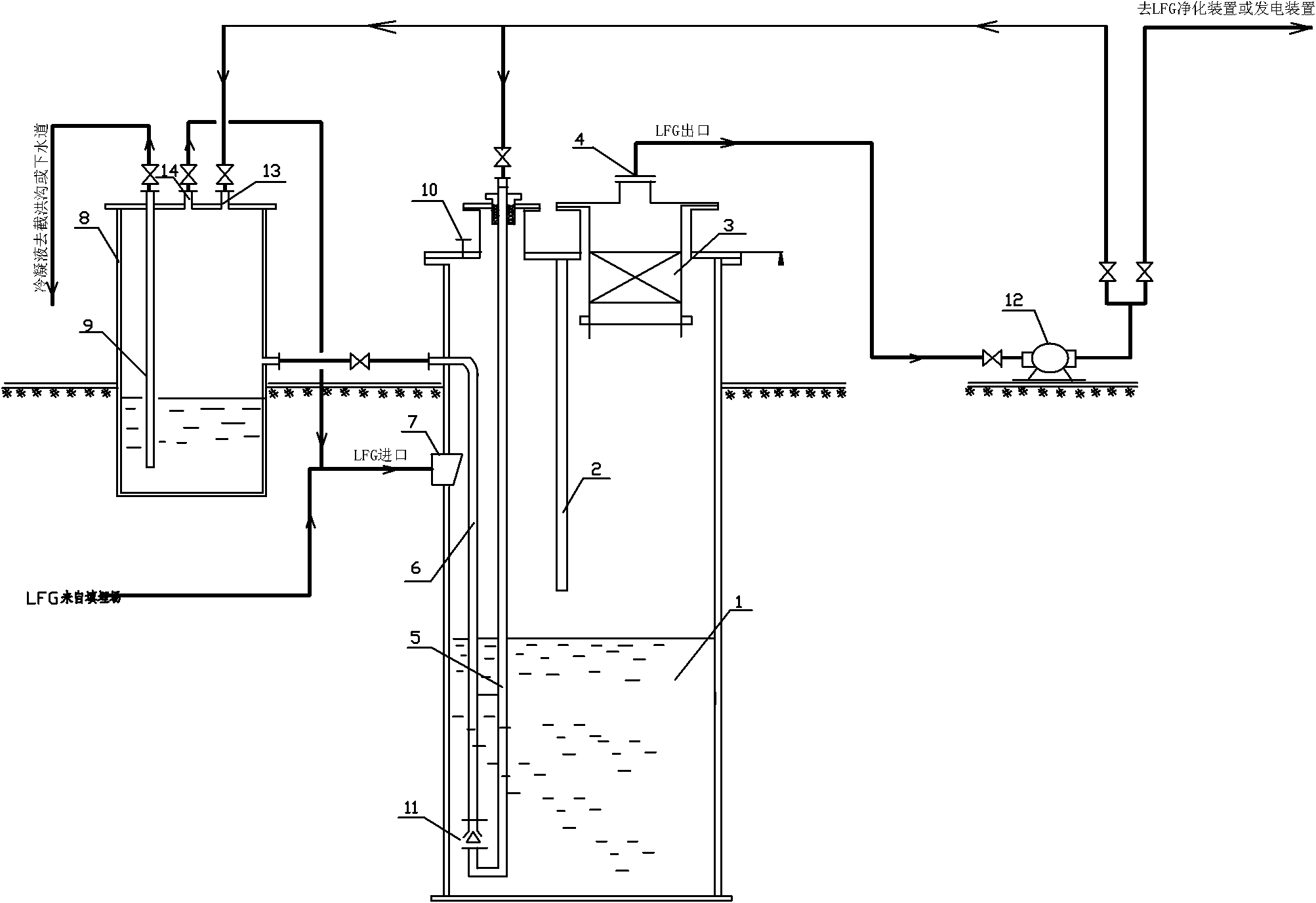

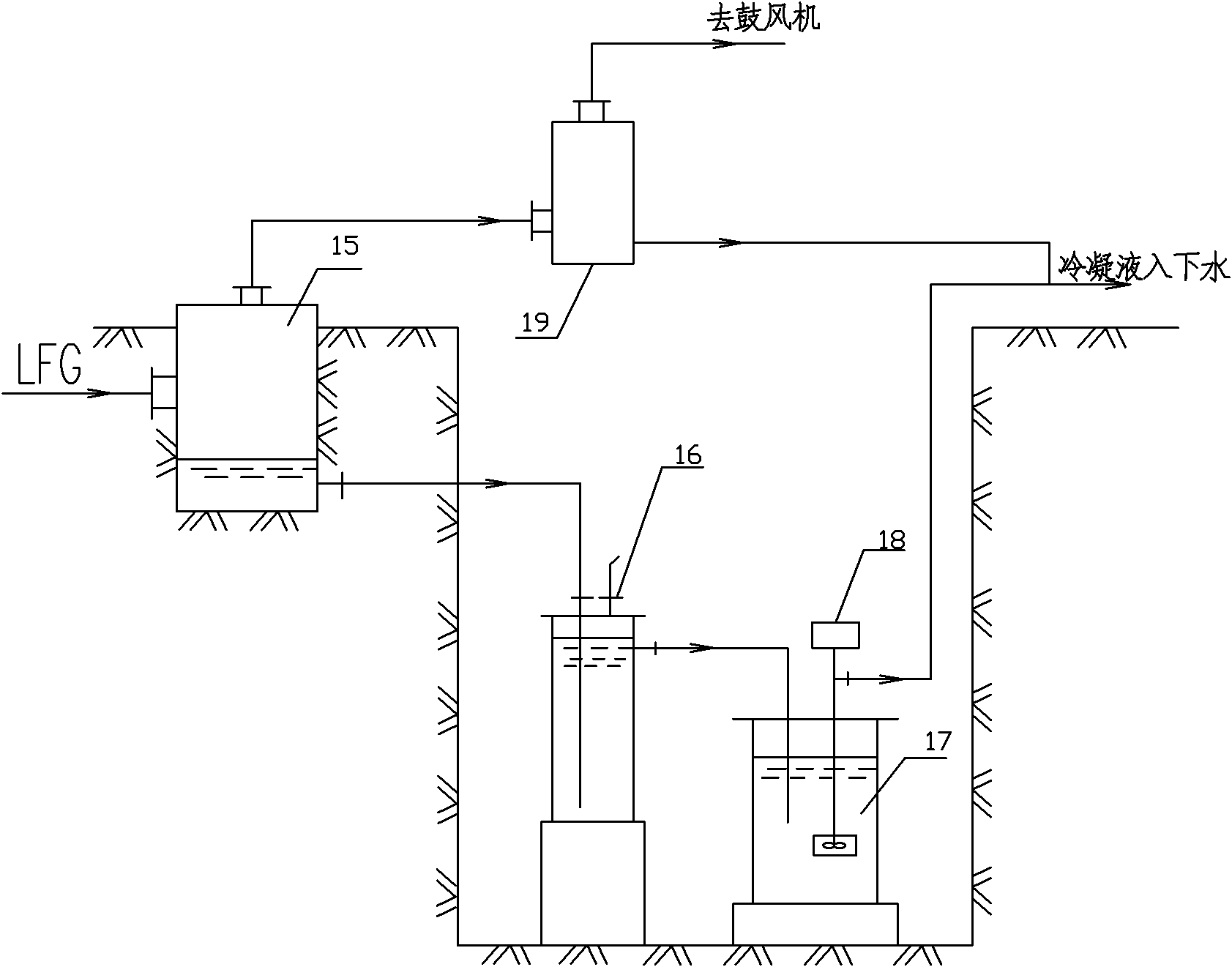

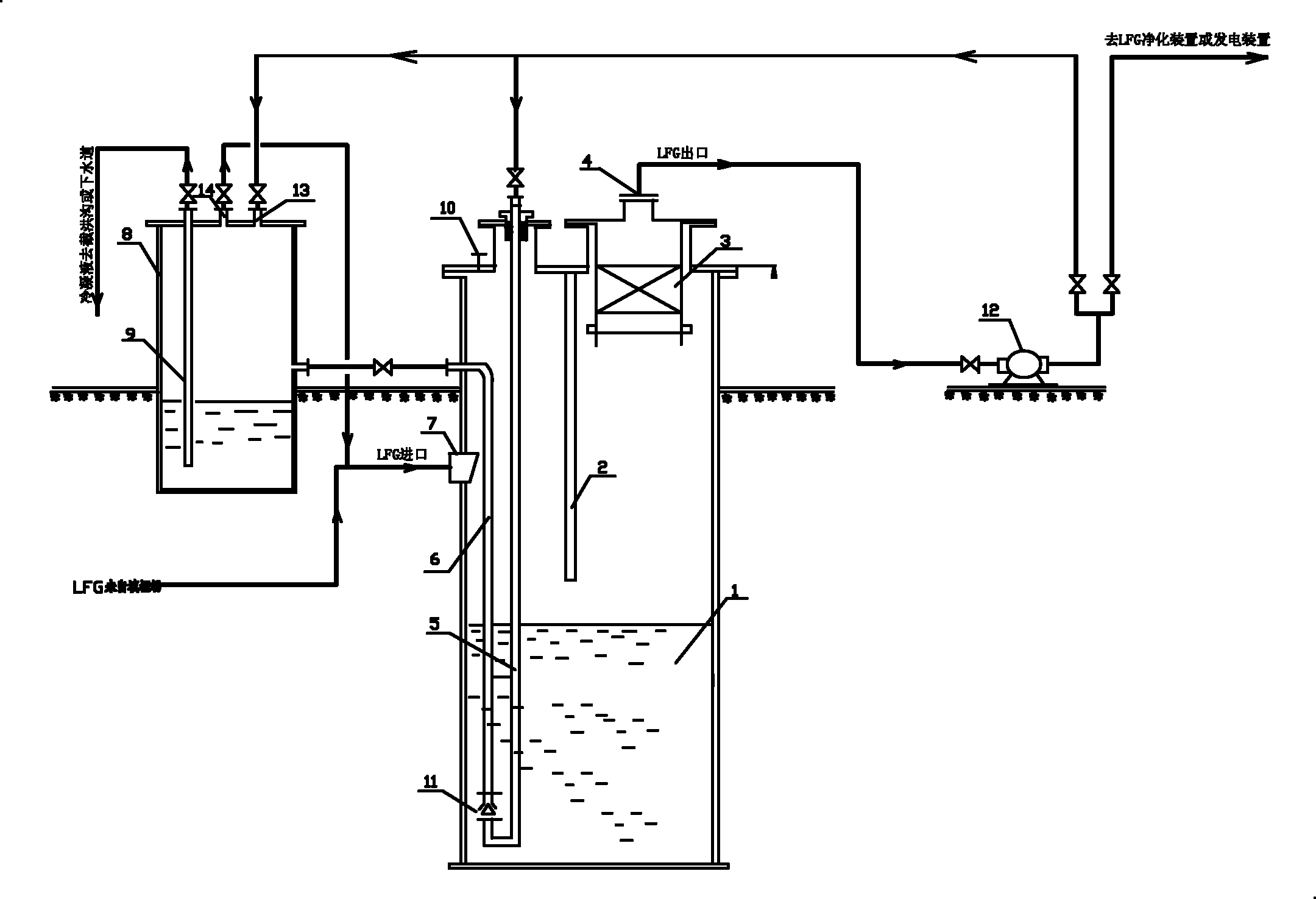

[0021] See figure 1 , a gas-liquid separation device, including a settling chamber 1, a baffle plate 2, a foam catcher 3, an LFG gas outlet pipe 4, an LFG gas inlet pipe 7, and a gas stripping medium separator 8, and the settling chamber 1 is provided with a condensate riser 6 and the baffle plate 2, the upper part is provided with a liquid level gauge interface 10, and the bottom of the condensate riser 6 is provided with a spray riser 11, and the condensate riser 6 is connected to the low-pressure landfill gas inlet pipe 5 output from the blower through the spray riser 11 Connection; the outlet at the top of the condensate riser 6 communicates with the gas stripping medium separator 8. The air-lifting medium separator 8 is provided with a low-pressure landfill gas inlet 13 output from the blower, and the air-lifting medium separator 8 is provided with a condensate discharge pipe 9, and the lower opening of the condensate discharge pipe 9 communicates with the condensate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com