Method for repairing bolt hole of cylinder cover

A bolt hole and cylinder head technology, applied in the field of machinery, can solve problems such as waste and scrapped cylinder heads, and achieve the effect of good leak trapping effect and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

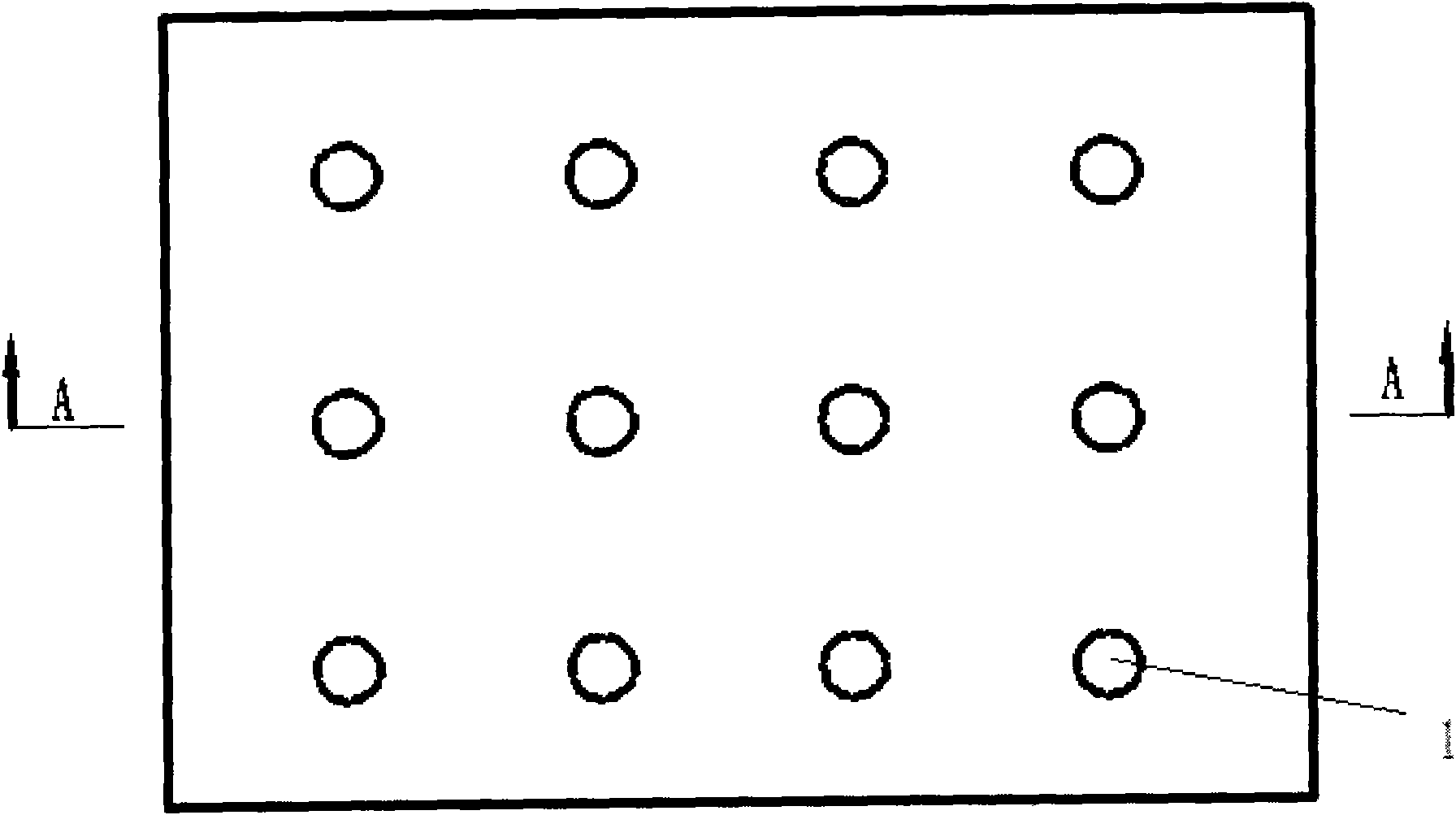

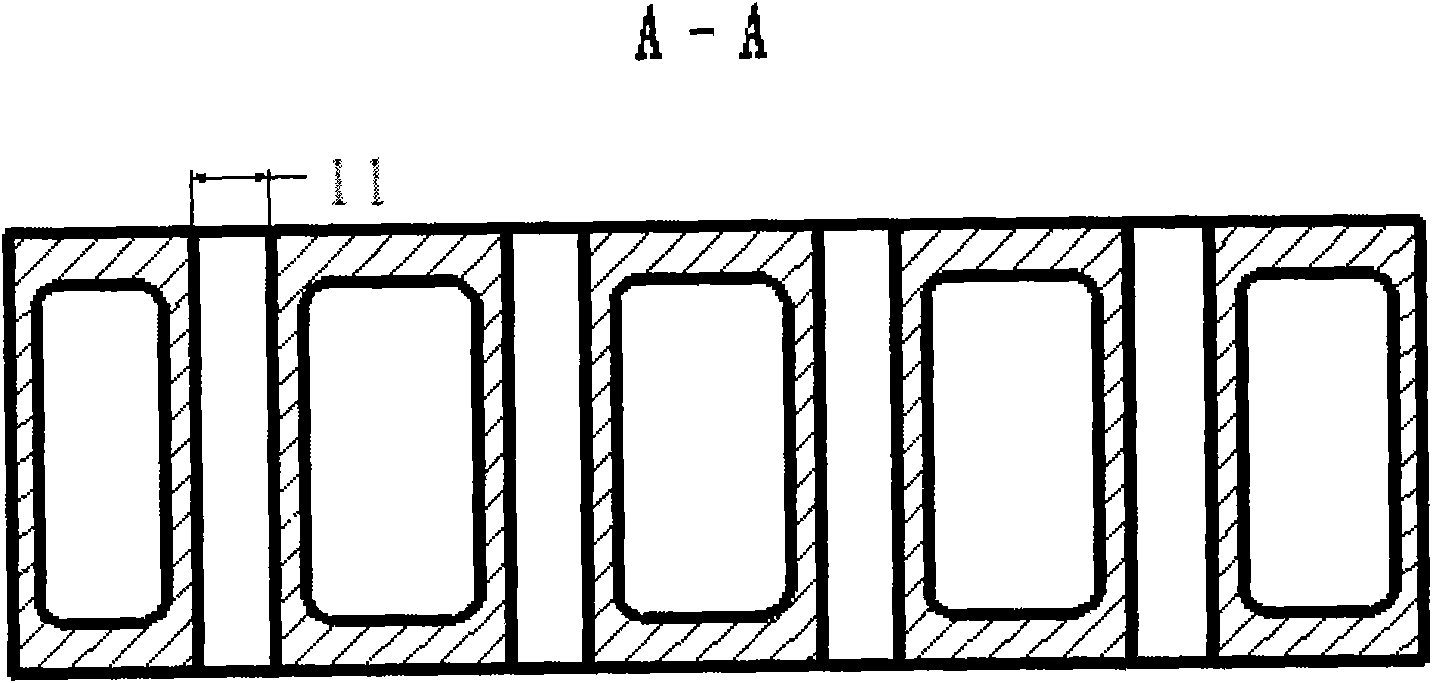

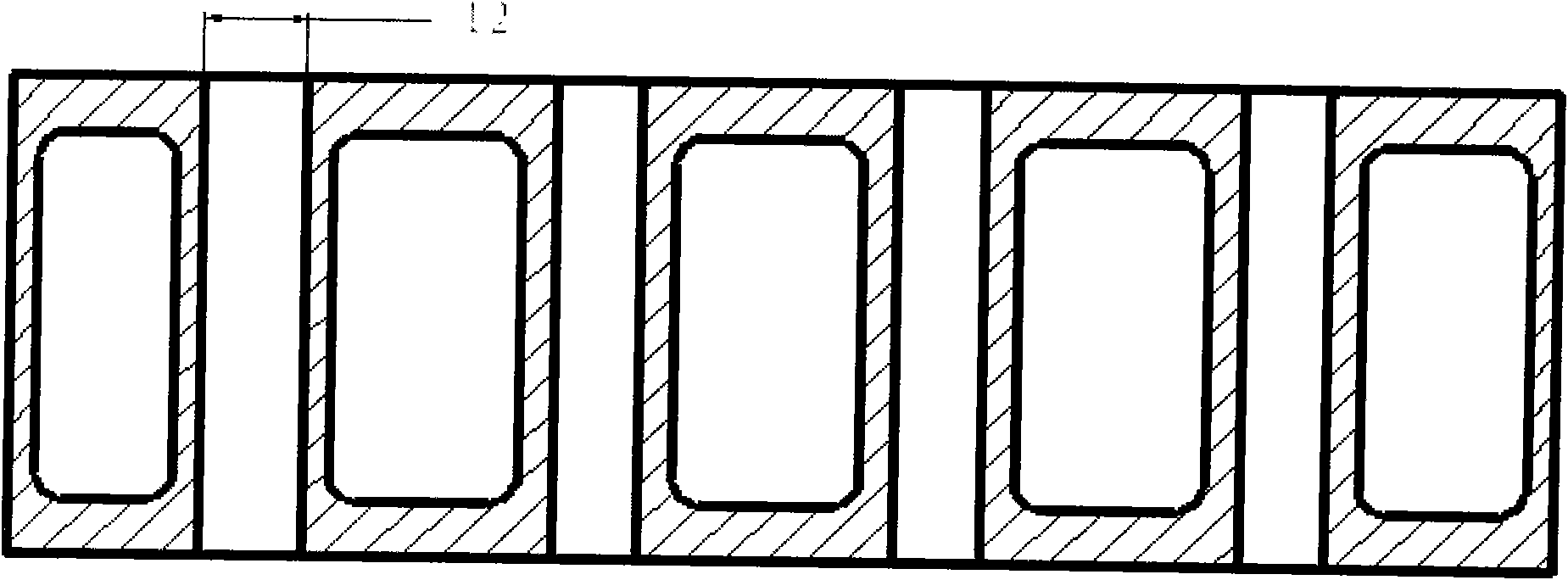

[0019] like Figure 1 to Figure 5 As shown, the cylinder head bolt hole repair method of the present invention is specifically as follows: first, the cylinder head bolt holes that have leaked have been reamed, that is, the bolt holes of Φ15mm are first expanded to Φ17.5mm; and then accurately reamed , that is, the fine reaming of the Φ17.5mm hole is (The tolerance range is -0.045 to -0.02mm), expand the original bolt hole to be repaired by 3mm; then apply repair glue on the enlarged bolt hole, and the repair glue is made of Luo alloy, alloy, ceramics, and diamond powder. Finally, the insert cooled by liquid nitrogen is pressed into the bolt hole, the insert is made of copper material, and the temperature of the liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com