Plastic building template system

A technology of building templates and templates, which is applied in the field of building auxiliary materials, can solve the problems of leakage of castables, loose joints of inner joints, and low compressive strength of connectors, and achieve the effect of improving the tightness of the joint and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

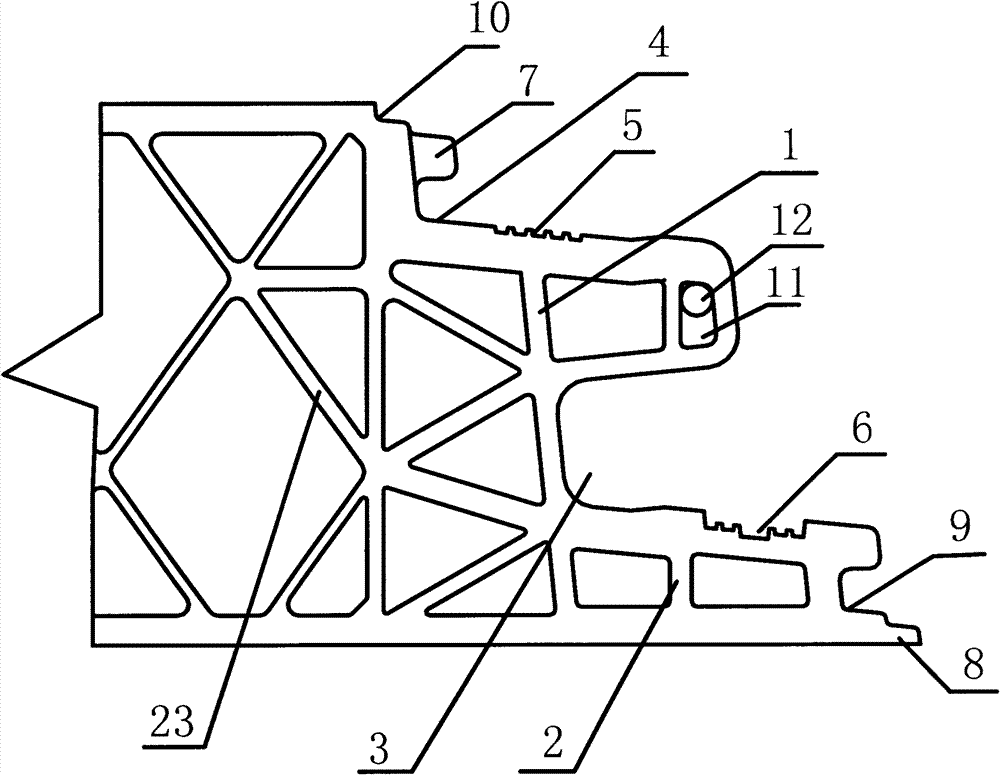

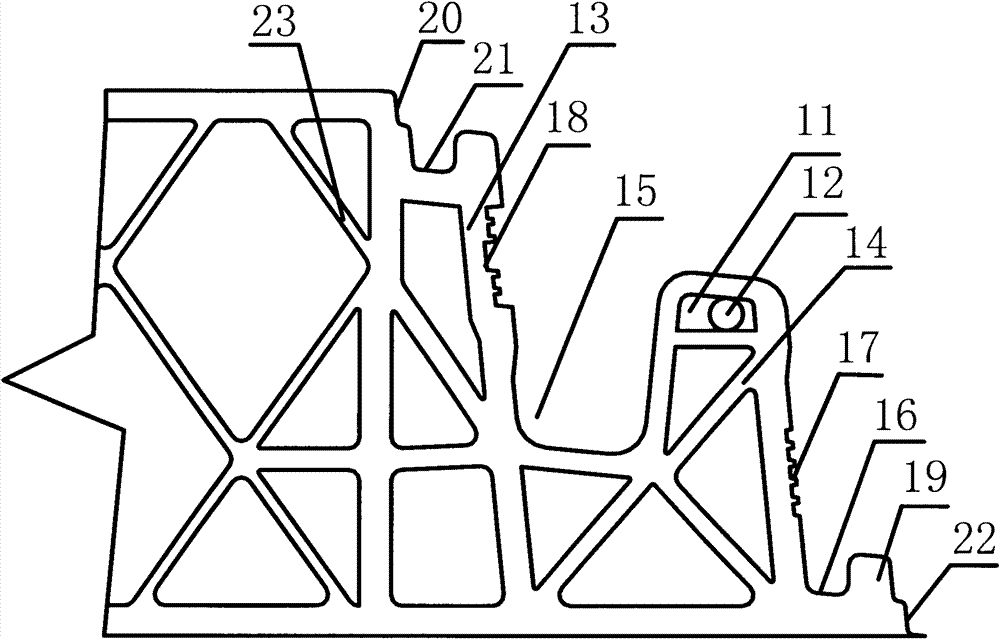

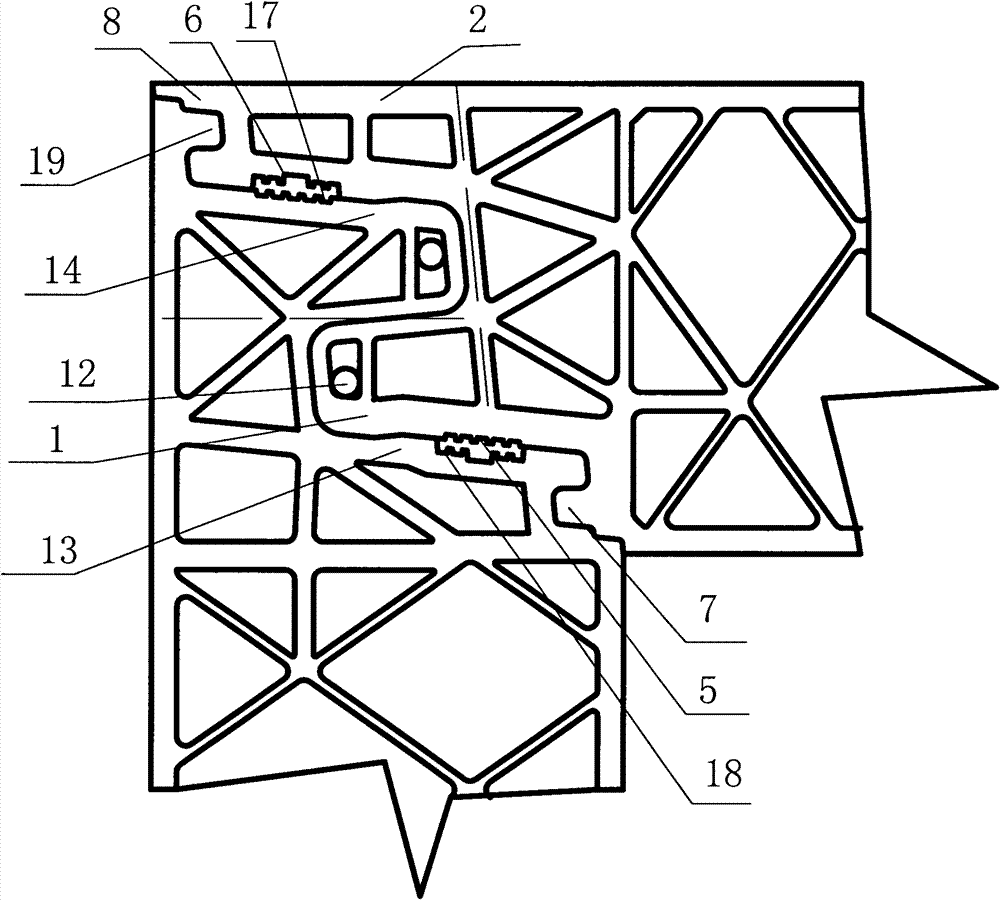

[0085] Combine figure 1 As shown, the present invention relates to a plastic building formwork system, which includes a first formwork spliced with each other to form a flat formwork system. The first formwork has two panels and a reinforcing rib 23 connecting the two panels. A plane connector is formed on the splicing edge of the template, and the plane connector, viewed from the cross section of the first template, includes:

[0086] The first chuck 1 and the second chuck 2 protruding to the adjacent template, the side of the first chuck 1 away from the second chuck 2 is on the same plane as a panel of the first template;

[0087] The first card slot 3 located between the first card head 1 and the second card head 2 and the second card slot 4 located on the side of the first card head 1 away from the first card slot 3;

[0088] A first fixing groove 5 arranged on the side wall of the first chuck 1 away from the first groove 3 and a first fixing groove 5 arranged on the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com