Multi-step spliced heat insulating door plate of electric rolling door

A technology for heat-resisting and rolling doors, which is applied in the direction of door leaves, fire doors, shutters/movable grilles, etc. It can solve the problems of reducing heat conduction area and difficult to avoid temperature, and achieves weight reduction of door panels, excellent fire protection performance, and overall weight reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

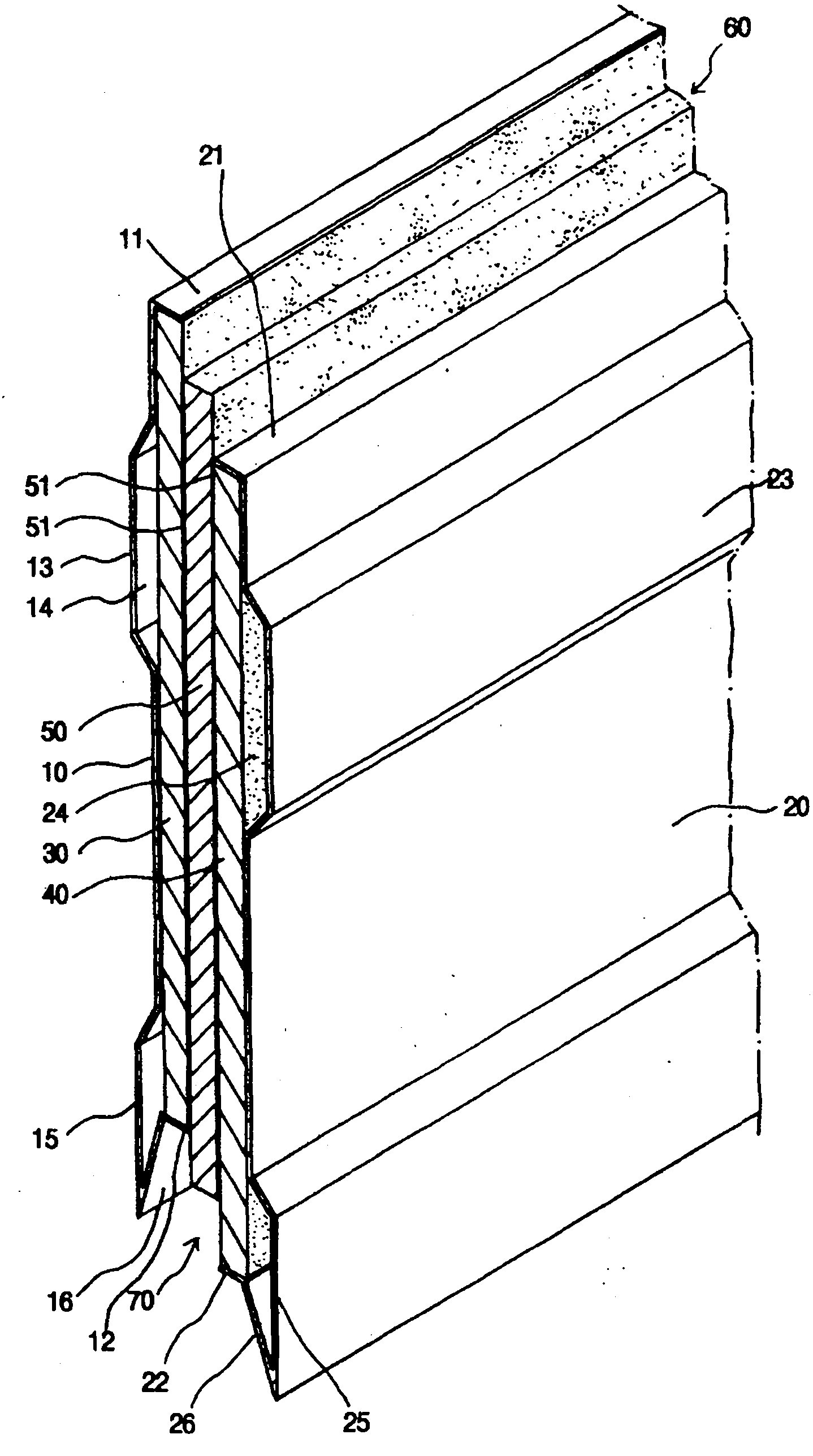

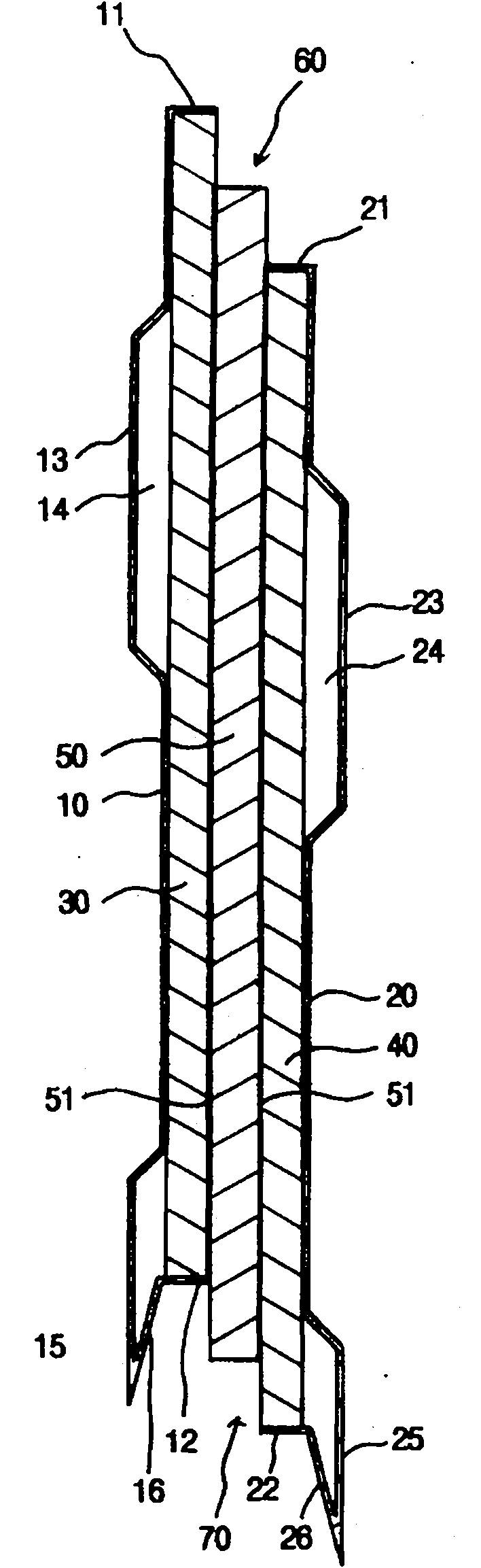

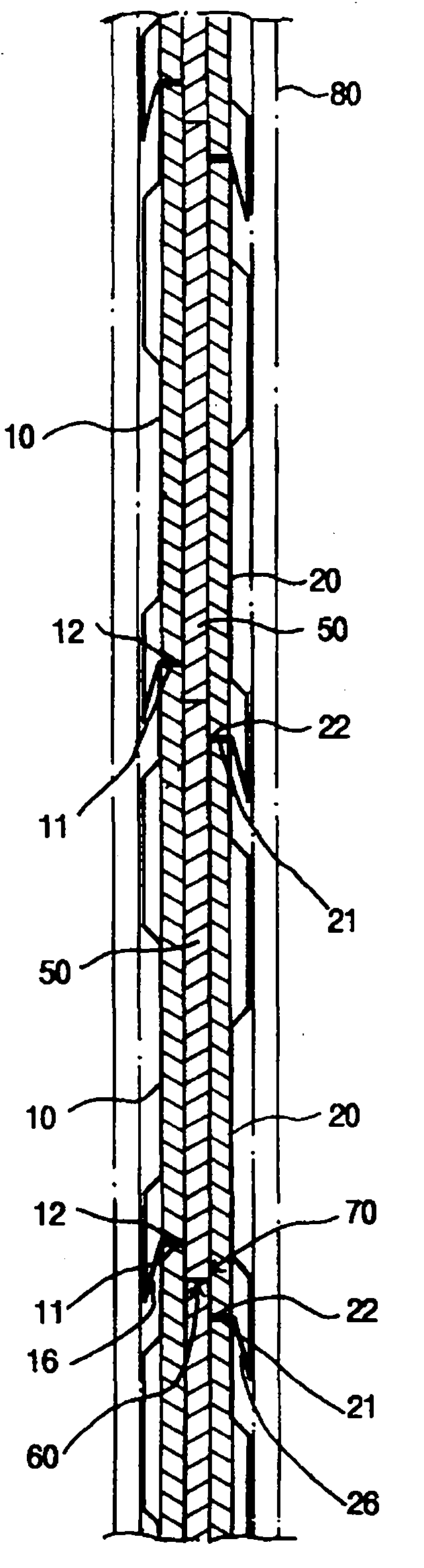

[0022] A multi-stage laminated heat-resistant door panel of an electric rolling door, such as figure 1 , 2 , which at least includes a first steel plate 10 and a second steel plate 20; the first steel plate 10 has a first upper fold 11 and a first lower frame 12 up and down, and inside the plate, the first An upper flange 11 and the first lower frame edge 12 are bonded together with a first ceramic fiber board 30; the upper end of the second steel plate 10 has a second upper flange 21 whose height is lower than the first upper flange 11, And the lower end has a second lower frame edge 22 that is lower than the first lower frame edge 12, and in the board surface, a second ceramic fiber board is bonded by the second upper edge 21 and the second lower frame edge 22. 40: The first and second ceramic fiber boards 30 and 40 are provided with at least one heat-resistant interlayer 50, so that the upper and lower parts of the door panel are respectively formed with a multi-step upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com