Spraying, cooling and exhausting muffler

An exhaust muffler and spray cooling technology, applied in mufflers, machines/engines, engine components, etc., can solve problems such as pollution, increase in muffler cost, and limitation of muffler volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

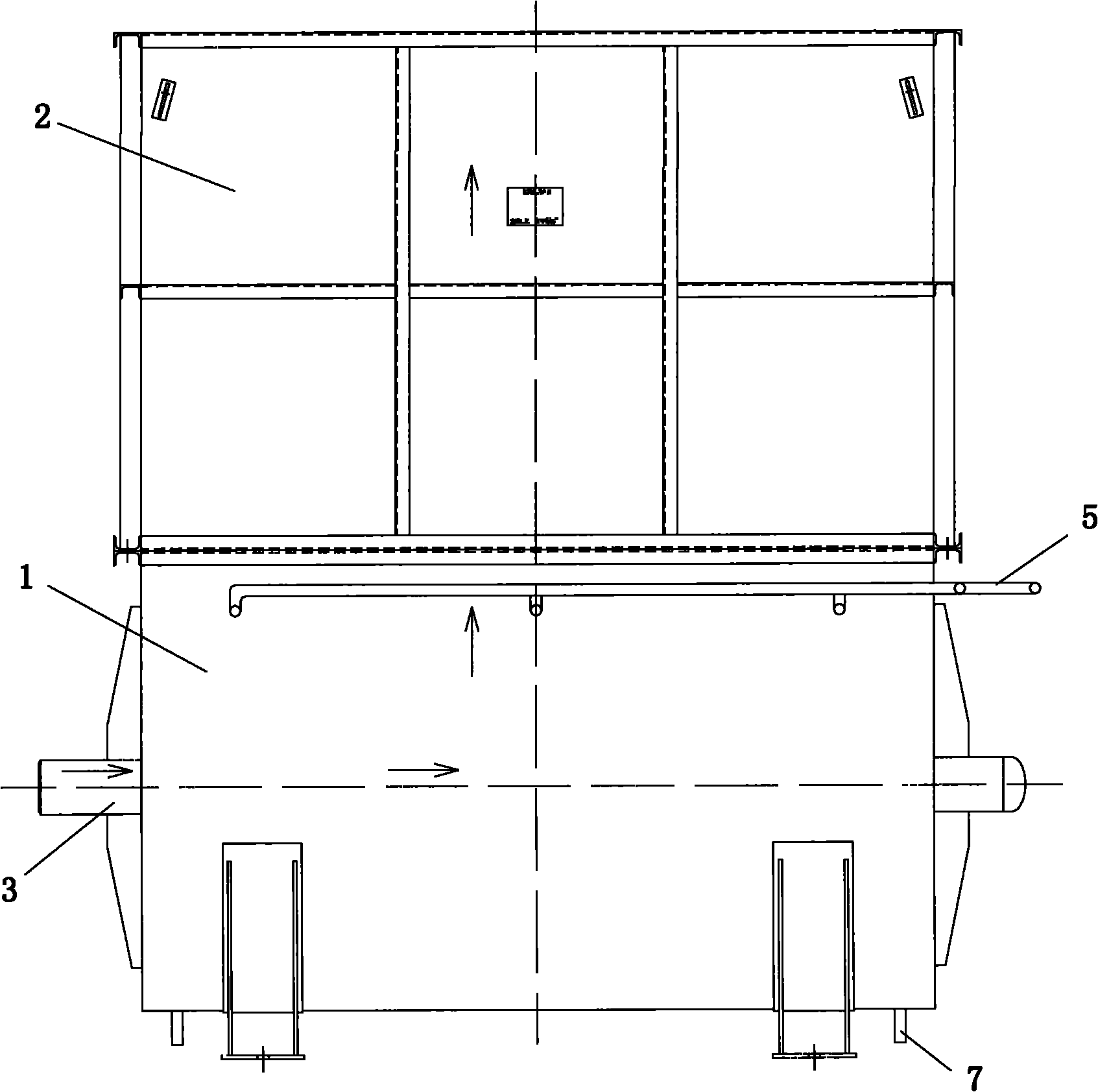

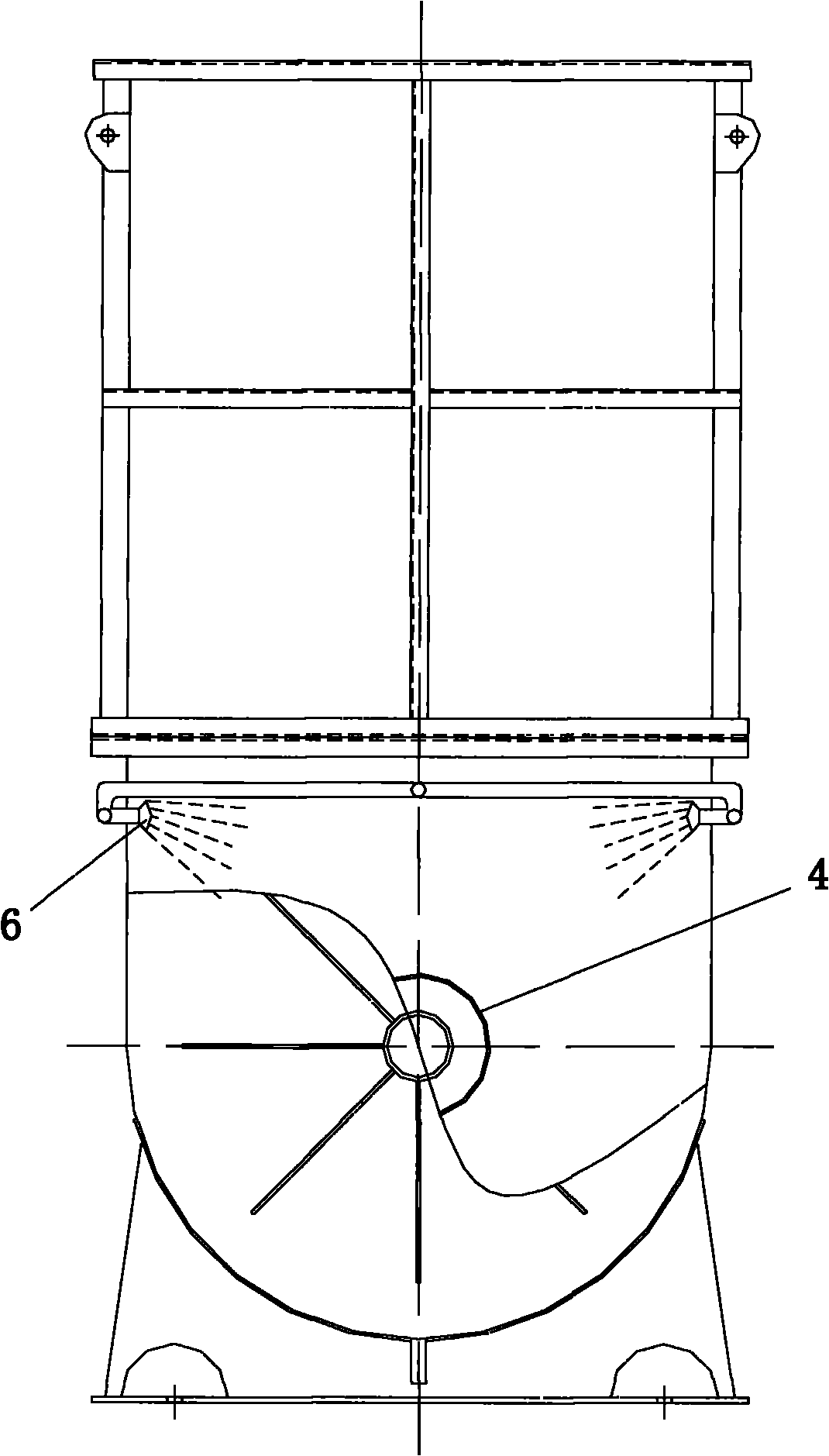

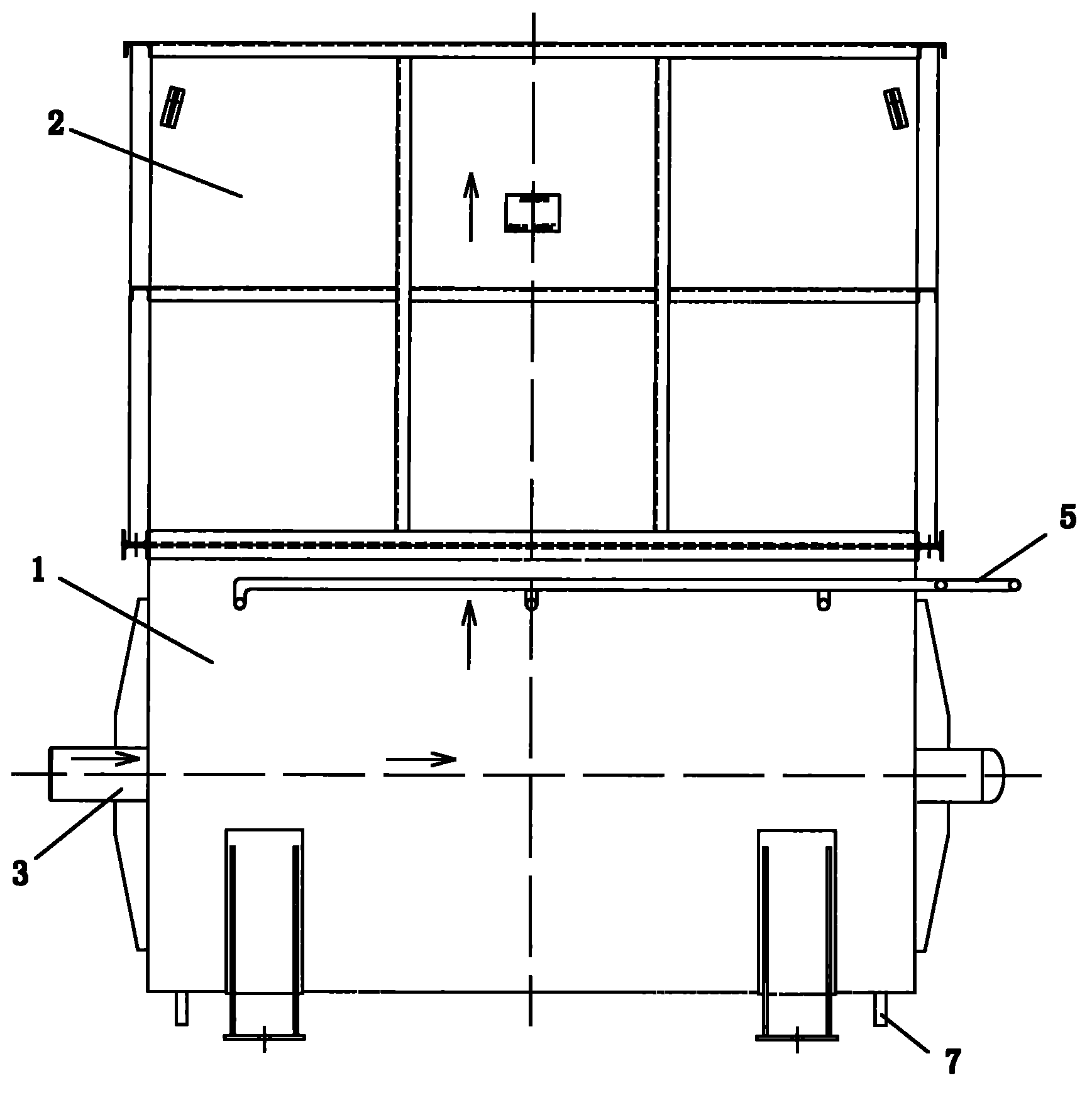

[0017] Each part in the attached drawing:

[0018] 1 Shell 2 Box 3 Inlet porous pipe

[0019] 4 coaxial perforated pipe 5 spray water pipe 6 water spray port

[0020] 7 drain pipe

[0021] figure 1 Shown is the front view of the muffler of the present invention, figure 2 It is a partial cross-sectional view of the muffler of the present invention. It can be seen from the figure that the spray cooling exhaust muffler consists of an inlet porous pipe 3, a coaxial porous pipe 4, a spray water pipe 5, a water spray port 6, a drain pipe 7, a housing 1 and The box consists of 2. In the present invention, the shell and its internal structure can be called a pre-muffler, and the box body and its internal structure can be called a follow-up muffler. The inlet porous pipe 1 of the spray cooling exhaust muffler of the present invention is a horizontal pipe with the same pipe diameter as the pipe flushing system and holes in the pipe wall. One end of it is open, and the pipe end ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com