Slide block type lubricating device for universal coupling slide block

A universal joint shaft, lubricating device technology, applied in the direction of engine lubrication, coupling, elastic coupling, etc., can solve the problem of high cost, good lubrication quality, automatic lubrication, economical and practical, and inconvenient maintenance of the protective cover. problems, to achieve the effect of simple structure, low equipment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

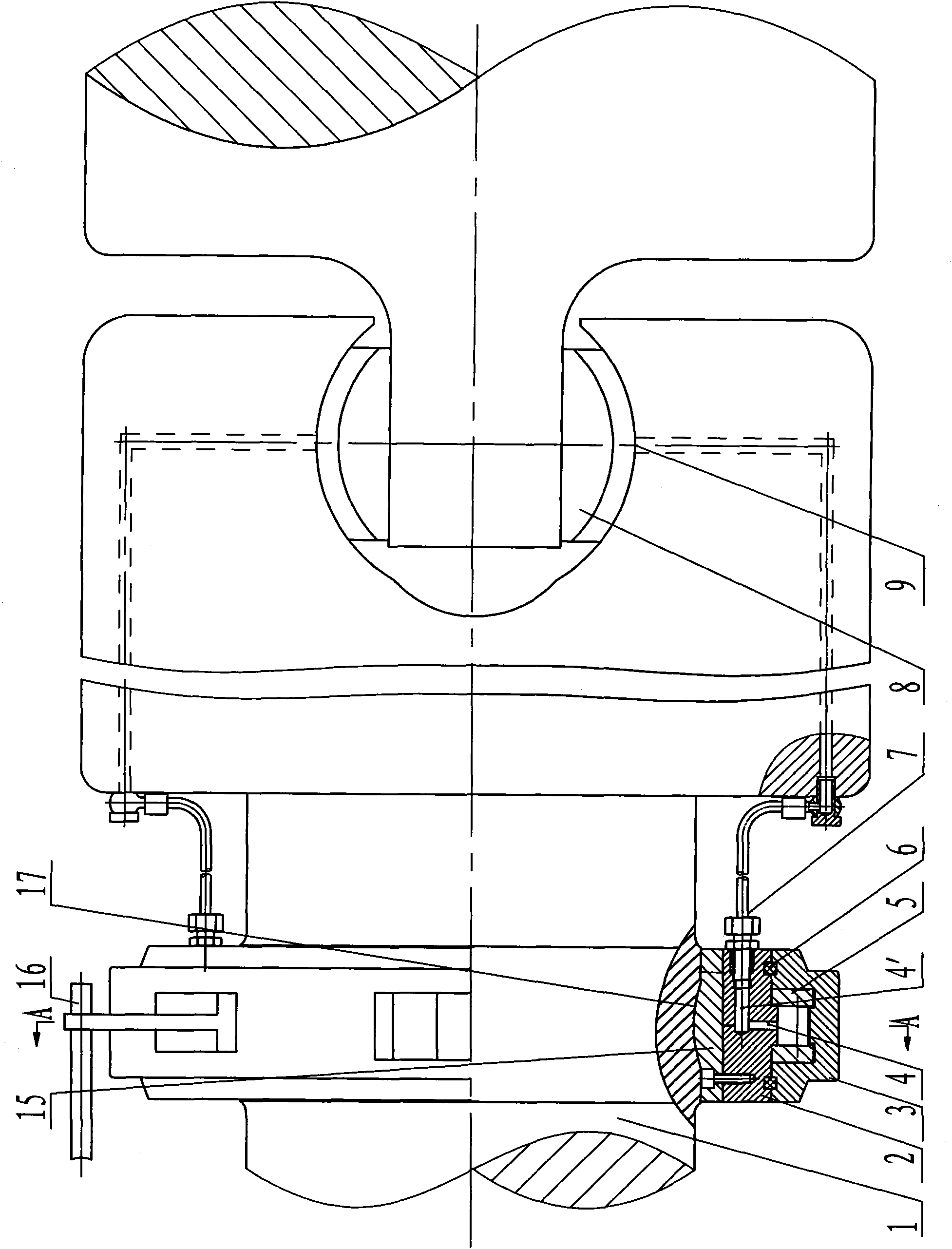

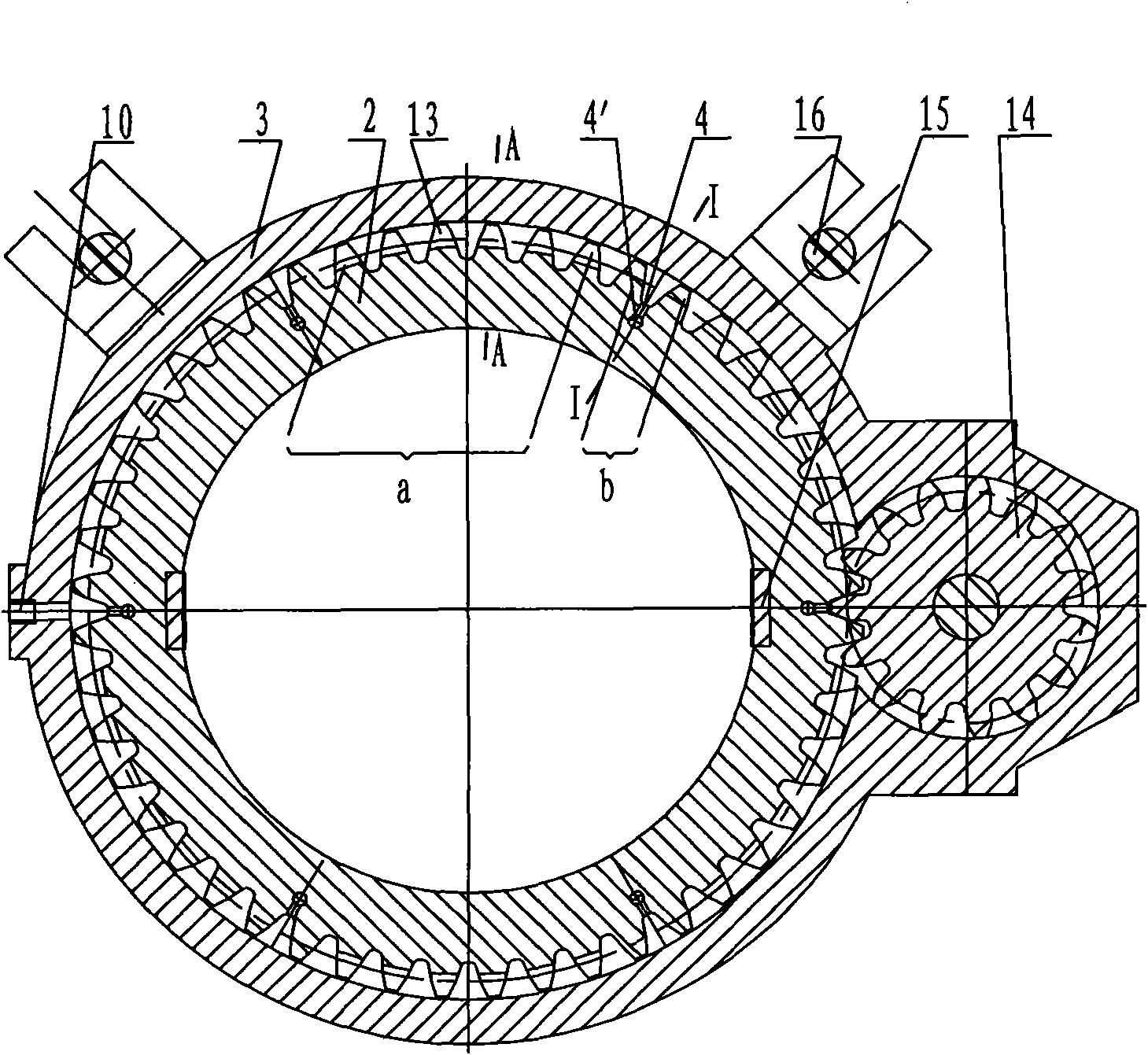

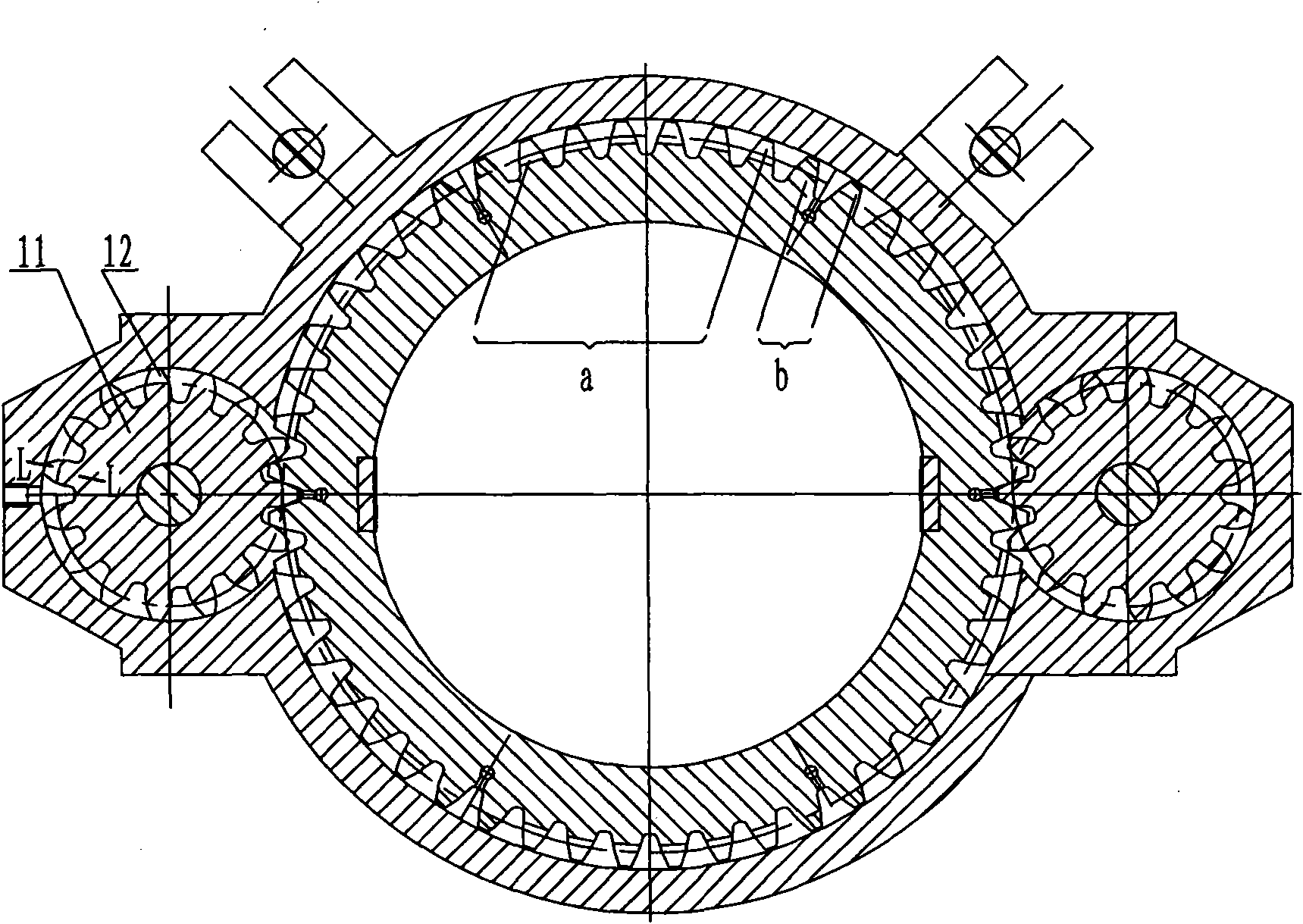

[0015] From figure 1 , figure 2 , Figure 4 , Figure 5 It can be seen that the lubrication device of the slider type universal joint shaft slider of the present invention includes a large gear 2, a sealing cover 3, and a small gear 14. The large gear 2 is fixed on the shaft 1 through a backing plate 15, and the large gear 2 is externally mounted There is a sealing cover 3, a sealing ring 6 is installed between the sealing cover 3 and the big gear 2, and an end cover 5 is sealed between the sealing cover 3 and the gear teeth of the big gear 2; a cavity is provided in the sealing cover 3, which A small gear 14 is installed inside. The small gear 14 has the same width as the large gear 2 and meshes with the large gear 2. An end cover 5 is sealed between the two ends of the gear teeth and the sealing cover 3; the sealing cover 3 is provided with an oil inlet 10; The gear teeth of the large gear 2 are divided into two types: one kind of gear tooth a has grooves 13 in the circumfere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com