Micro negative pressure heat radiator

A radiator and micro-negative pressure technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of corroded heating, shortening of heating life, large pressure changes, etc., to achieve easy cleaning , Not easy to hurt people, not easy to corrode effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

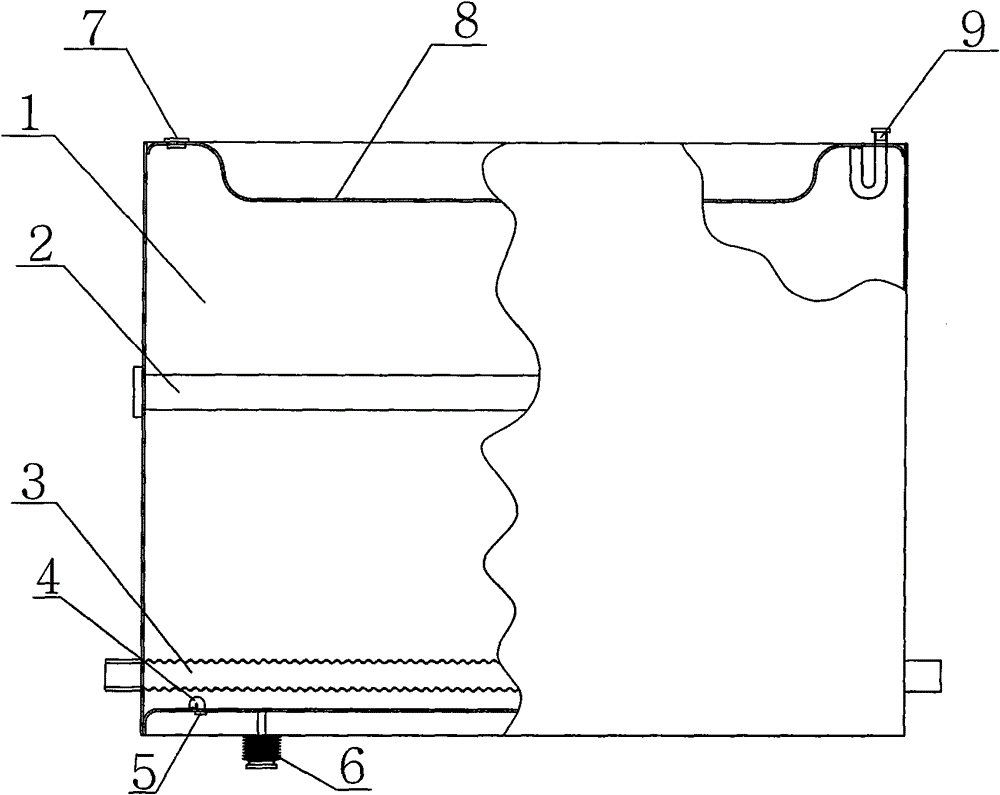

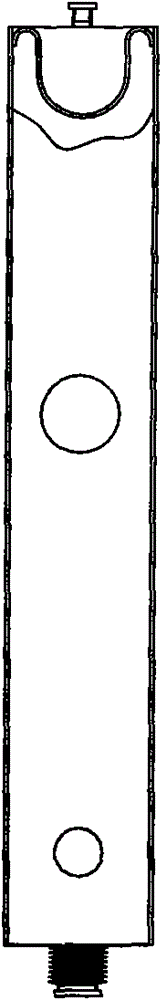

[0011] Refer to attached figure 1 , the present invention comprises a fully enclosed box body 1, is provided with heat exchange tube 3 in box body 1, and the two ends of heat exchange tube 3 extend out box body, is provided with liquid injection port 7 on box body 1, and liquid injection The mouth is closed by a plug, and a pressure relief hole 5 is provided at the bottom of the box body. An inverted "U"-shaped pipe 4 is installed on the pressure relief hole 5, and is closed by a plug. The expansion bag 6, the external expansion bag 6 is an expansion bag that can store liquid; the heat exchange tube is made of stainless steel corrugated tube, which has high heat exchange efficiency and corrosion resistance. An open water tank 8 embedded in the box is provided on the top of the box, and an exhaust valve 9 is provided on the box; an electric heating rod 2 can also be installed in the box 1, and the electric heating rod 2 is installed on the heat exchange tube 3 above. When in ...

Embodiment 2

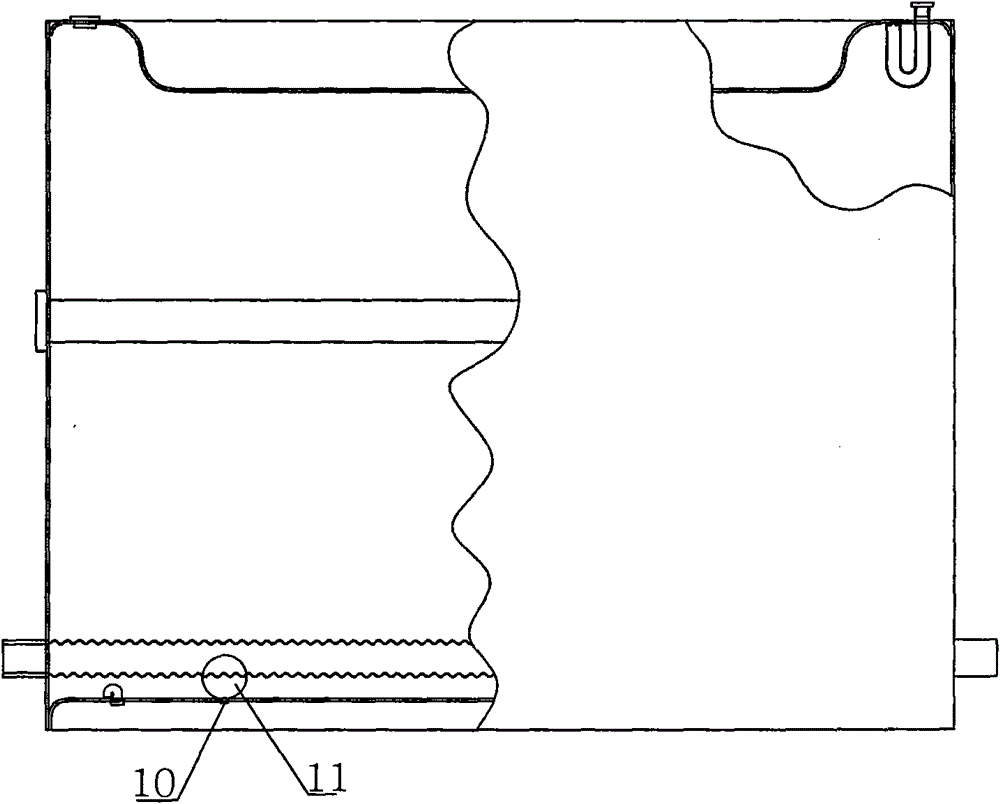

[0013] Refer to attached image 3 , its basic structure is the same as that of Example 1, except that the external expansion bag 6 is replaced by a built-in expansion bag 11. Gas valve 10. When in use, inflate the expansion bag first. When heating, when the heat medium expands, it will squeeze the expansion bag, and the expansion bag will exhaust outwards, so that a slight negative pressure will be generated in the box, so as to ensure that the box will not be deformed under pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com