Ultrasonic flower meter for eliminating zero point error

A zero point error and ultrasonic technology, applied in the field of ultrasonic flowmeter, can solve the problems of large zero point error of ultrasonic flowmeter, large measurement error of flowmeter, ultrasonic propagation time difference, etc., and achieve the effect of eliminating zero point error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described with reference to the accompanying drawings.

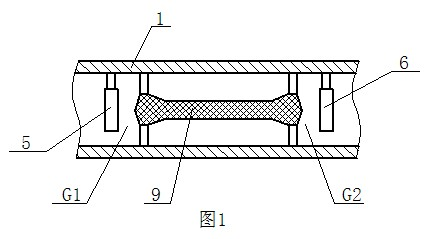

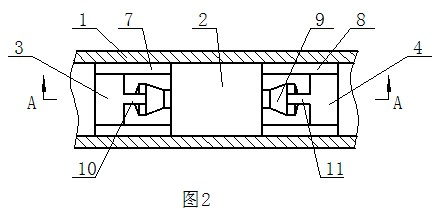

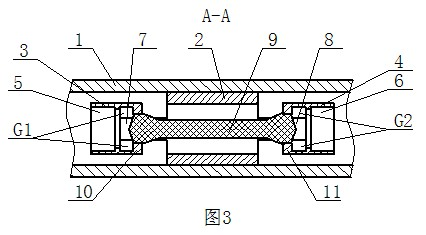

[0008] The main design of the ultrasonic flowmeter for eliminating zero-point error of the present invention is to use a sound guide column to divide the sound wave into two paths, one path is a fast sound wave, and the other path is a slow sound wave. The fast sound wave is used to measure the error time difference formed by the asymmetry of the circuit and the probe, and the slow sound wave is used to measure the composite time difference of the real time difference and the error time difference, and then subtract the error time difference from the composite time difference to obtain the real time difference, from The zero point error is basically eliminated. Therefore, the ultrasonic flowmeter for eliminating zero point error according to the present invention has a main structure of an outer tube 1, an ultrasonic transmitting probe and an ultrasonic receiving probe are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com