Manufacturing method of piezoresistive acceleration sensor based on son structure

The technology of an acceleration sensor and its manufacturing method is applied in the direction of acceleration measurement using inertial force, microstructure technology, microstructure device, etc., which can solve problems such as measurement errors of piezoresistive acceleration sensors, and achieve zero-point error elimination, good mechanical properties, The effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

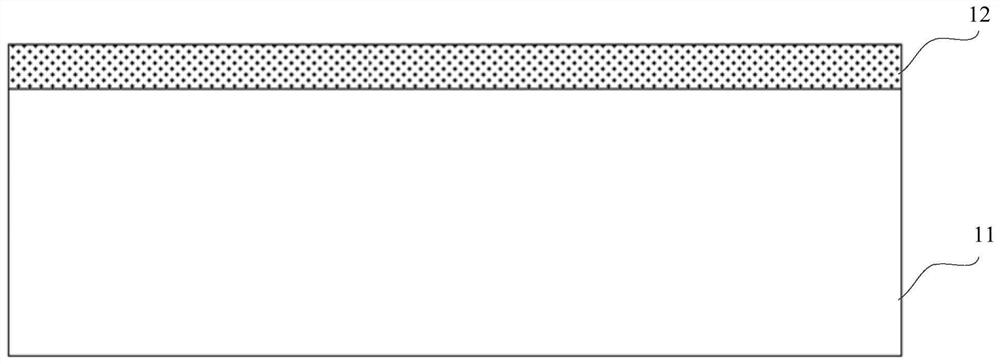

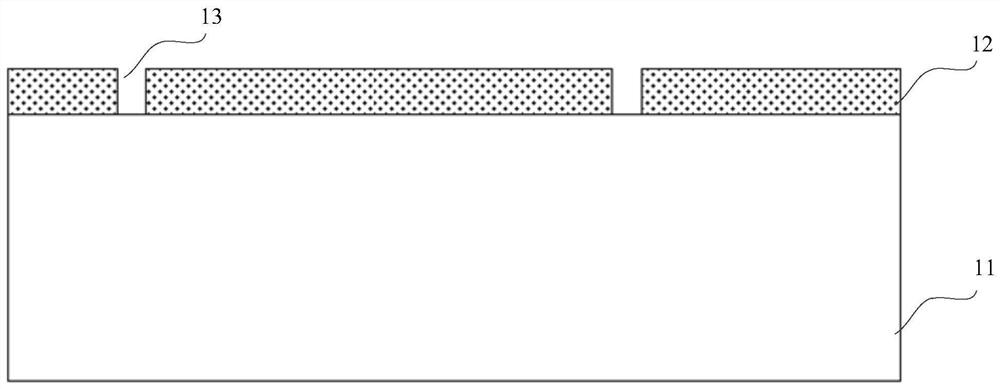

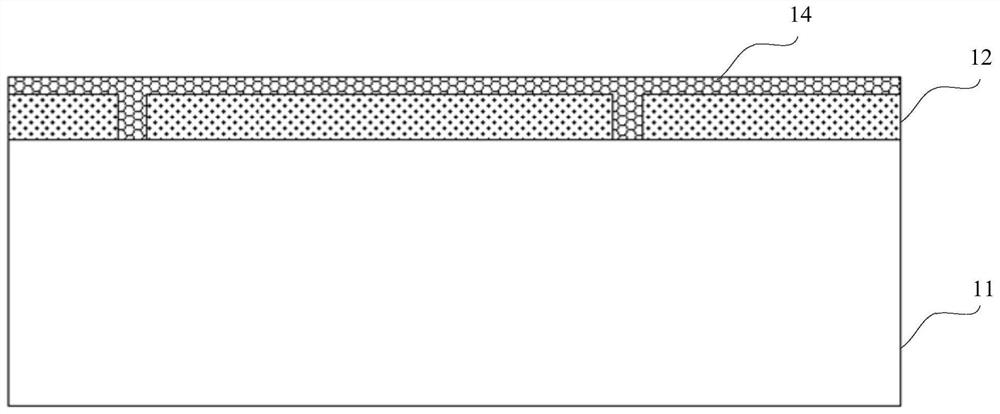

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0039] The present application provides a method for manufacturing a piezoresistive acceleration sensor based on a SON structure. The piezoresistive acceleration sensor based on a SON structure belongs to a MEMS device, and the preparation process is based on a MEMS process platform. The piezoresistive acceleration sensor based on the SON structure includes a SON (Silicon-on-Nothing) cavity structure at the lower part, and a MEMS acceleration sensor structure at the upper part; a sensitive film and a force sensitive resistor are arranged in the upper part of the MEMS acceleration sensor structure , when the MEMS acceleration sensor structure is applied acceleration, the sensitive membrane structure is deformed, the resistance of the for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com