A Calibration System of High Precision Laser Scanning Mirror Position Sensor

A laser scanning galvanometer and calibration system technology, which is applied in the field of high-precision laser scanning galvanometer position sensor calibration systems, can solve the problems of lack of, difficult to achieve scanning galvanometer position sensor calibration, etc., to achieve precise positioning and continuous rotation, reduce The effect of small measurement error and elimination of installation deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

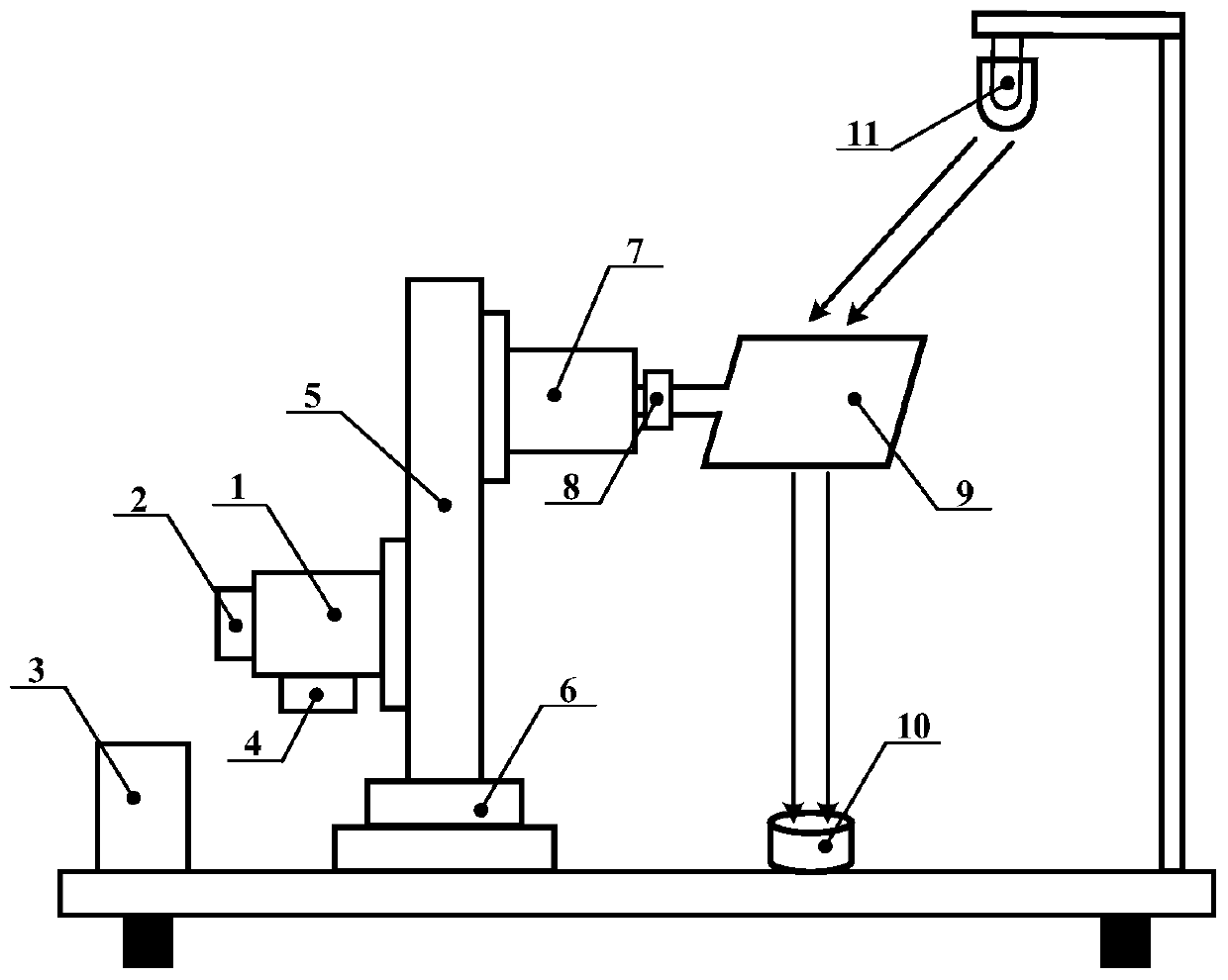

[0052] figure 1 It is a high-precision laser scanning galvanometer position sensor calibration system of the present invention, which consists of a permanent magnet synchronous motor 1 with low torque pulsation, a high-precision angular position sensor 2, a computer control system 3, a permanent magnet synchronous motor driver 4, and a reducer 5 , a zeroing mechanism 6, a calibrated galvanometer motor 7, a calibrated galvanometer 9, a calibrated angular position sensor 8, a laser source 11 and a photoelectric position detector 10.

[0053] Among them, the permanent magnet synchronous motor 1 with low torque ripple adopts a surface-mounted three-phase permanent magnet synchronous motor with 22 poles and 24 slots. thermal stability.

[0054] Among them, the high-precision angular position sensor 2 adopts the 17-bit absolute photoelectric senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com