Finite element numerical model debugging method based on grid structure

A grid structure and numerical model technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as time-consuming, model errors, errors that need to be eliminated one by one, repeated repeatedly, etc., to achieve Overcoming time-consuming and laborious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

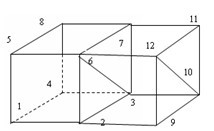

[0046] Step 2 Number the surface elements in the 2 hexahedral 8-node units, the 6 surface elements of unit 1 are 1 2 3 4; 2 6 7 3; 3 7 8 4; 4 8 5 1; 1 5 6 2; 5 8 7 6; the 6 bins of unit 2 are 2 9 10 3; 9 12 11 10; 10 11 7 3; 3 7 6 2; 2 6 12 9; 6 7 11 12. Panels are numbered sequentially 1-12.

[0047] Among the 12 bins, there is no bin with zero area, n0=0.

[0048] Model left boundary xmin=0; model right boundary xmax=20; model front boundary ymin=0; model rear boundary ymax=10; model upper boundary ymax=10; model lower boundary ymin=0.

[0049] Among the 12 spatial elements, Nos. 1 and 7 are the lower boundary elements, No. 6 and 12 are the upper boundary elements, No. 4 is the left interface element, No. 8 is the right interface element, and No. 5 and 11 are the The front boundary interface, No. 3 and 9 are the rear boundary interface. The total number of boundary surface elements is n1=10, and the remaining surface elements are 2.

[0050] Step 3 Among the 2 remaining ...

Embodiment 2

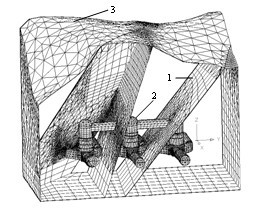

[0053] (1) Classify the finite element grid information into node information and unit structure information, including the number of nodes and units, node coordinates, unit structure shape, information on building unit structure by node numbers; the total number of nodes is 38954, and the total number of units for 184336.

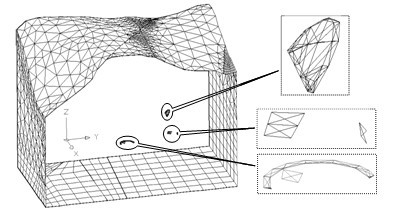

[0054] (2) Transform tetrahedral elements and triangular prism elements into hexahedral 8-node elements. Split each 6-hedron 8-node unit into 6 space elements, analyze the properties of each surface element, and eliminate the surface elements with obvious characteristics (zero area and boundary surface elements).

[0055] (3) Perform grid self-retrieval. Analyze whether each unit body satisfies the rules of numerical calculation through the surface element correspondence of each unit body. By judging whether each surface element is shared by two or more unit bodies, if a certain surface element is only used by one unit body, it is a Potential error bins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com