Rotor rubbing acoustic emission signal denoising method

An acoustic emission signal and emission signal technology, which is applied in the directions of sound-emitting instruments, measuring devices, instruments, etc., can solve the problems of noise pollution of acoustic emission signals, inability to reflect the rubbing state of rotating machinery, etc., and achieves fast noise reduction, multiplication and division operations. Less, improve the effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

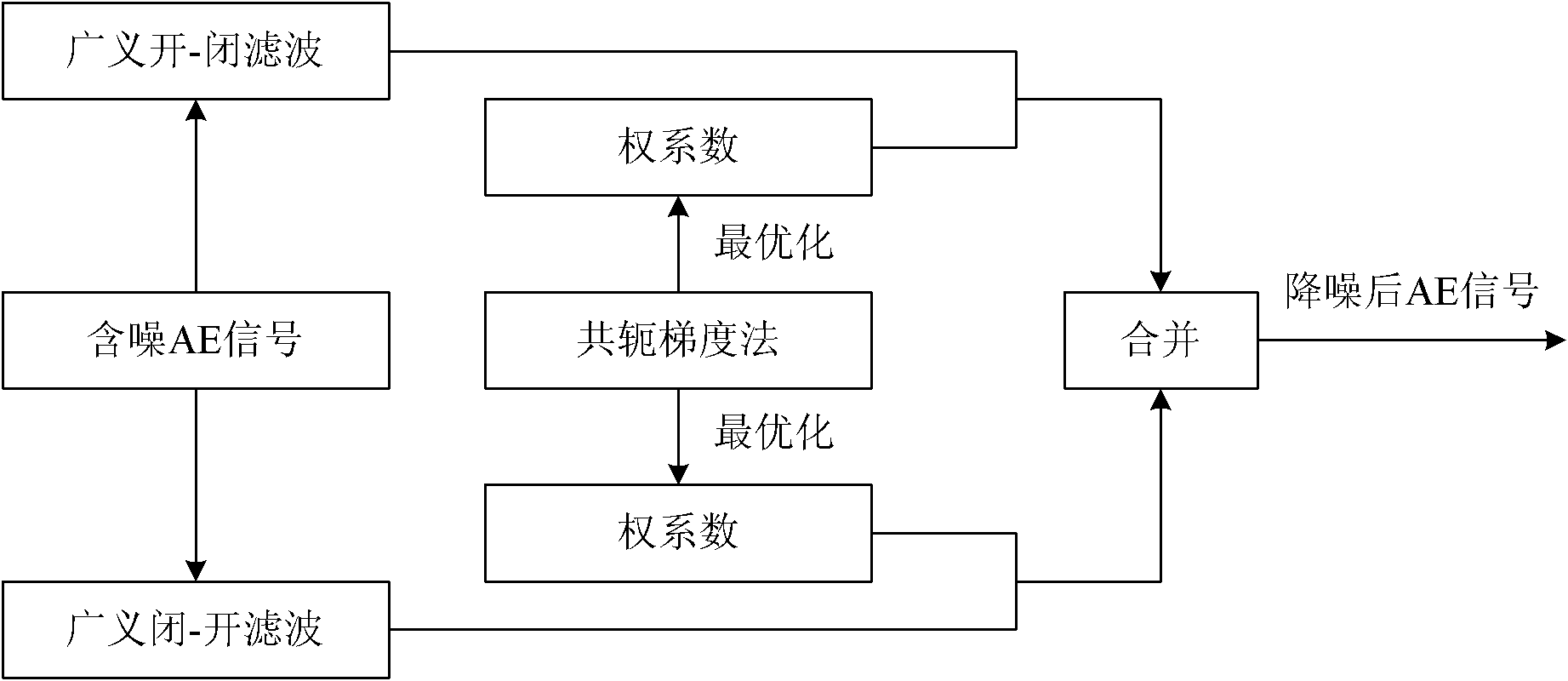

[0020] figure 1 It is an overall flowchart of the method for noise reduction of rotor rubbing acoustic emission signal based on conjugate gradient method and adaptive generalized morphological filtering. The steps of this method are as follows:

[0021] (1) Using the rubbing acoustic emission experimental device to obtain the noise-containing rubbing acoustic emission signal;

[0022] (2) Carry out generalized open-close and close-open filtering to the noise-containing rubbing acoustic emission signal obtained in step 1, and obtain the output signals of generalized open-close and close-open filters respectively;

[0023] (3) The initial weight coefficients of the generalized open-close and close-open filters are set to be 0.5, and the weight coefficients of the generalized open-close and close-open filters are adaptively transformed to optimal values by using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com