Fixed structure of carbon brush fixed sheet

A fixed structure and fixed piece technology, applied in current collectors, electrical components, rotary current collectors, etc., can solve the problems of loose solder joints, deformation of carbon brush fixed pieces, and failure of regulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

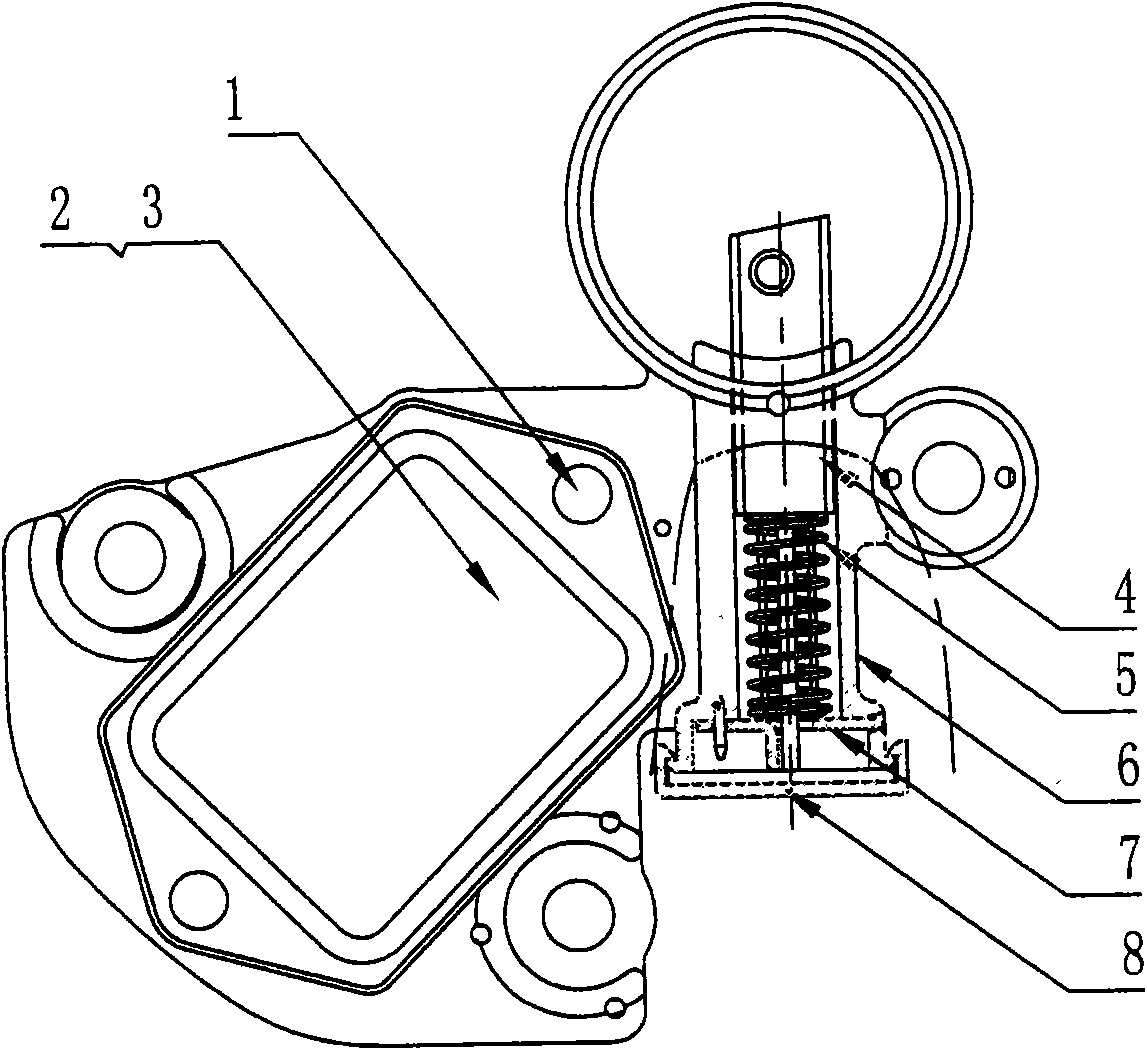

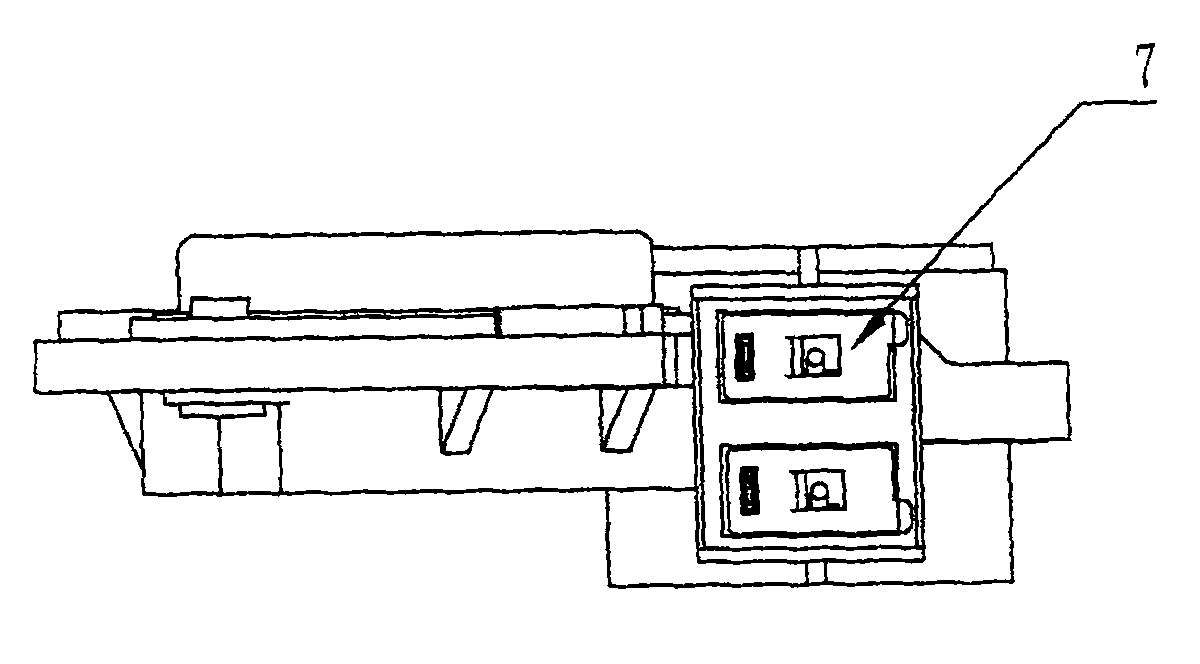

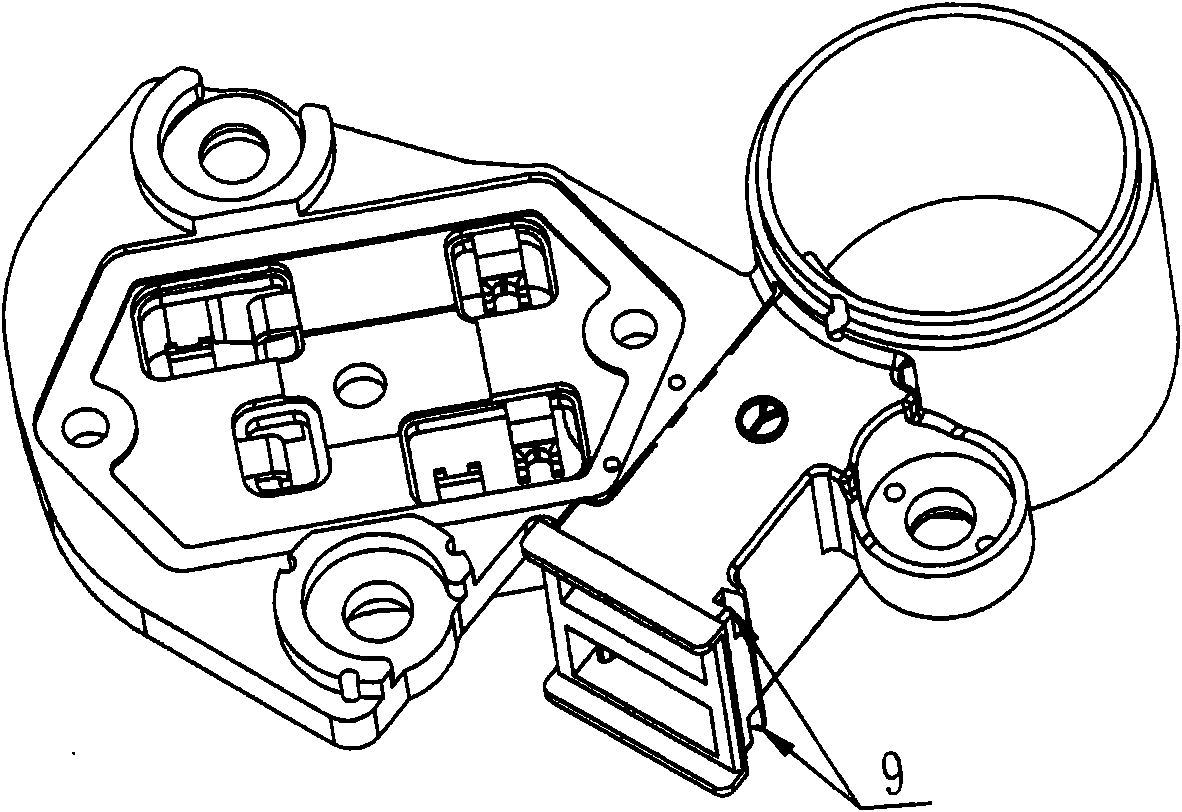

[0011] Reference figure 1 , figure 2 with image 3 Among them, the present invention includes an adjuster bracket, a carbon brush, a carbon brush fixing piece, a carbon brush protective cover, and a notch. First, a new carbon brush fixing piece (7) is made by stamping, and an adjuster bracket (6) is made by injection molding. A gap (9) is provided on the adjuster bracket, and the carbon brush (4) The lead wire passes through the spring (5), and then the lead wire of the carbon brush (4) is welded to the carbon brush fixing piece (7). Insert one side of the carbon brush fixing piece (7) into the gap of the regulator bracket (6), and fix the carbon brush fixing piece (7) on the regulator bracket (6) by soldering. Then install the carbon brush protective cover (8) on the regulator bracket (6), and finally rivet the thick film (2) and the heat sink (3) on the regulator bracket (6) with rivets (1) to form the regulator .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com