Equipment having rotary pistons usable as compressors, pumps, vacuum pumps, turbines, motors and other driving and driven hydropneumatic machines

A technology of rotary piston and compressor, applied in the direction of rotary piston engine, rotary or oscillating piston engine, rotary piston pump, etc., can solve the problems of heavy equipment, expensive manufacturing, low vacuum rate, etc., to reduce friction, prolong longevity, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

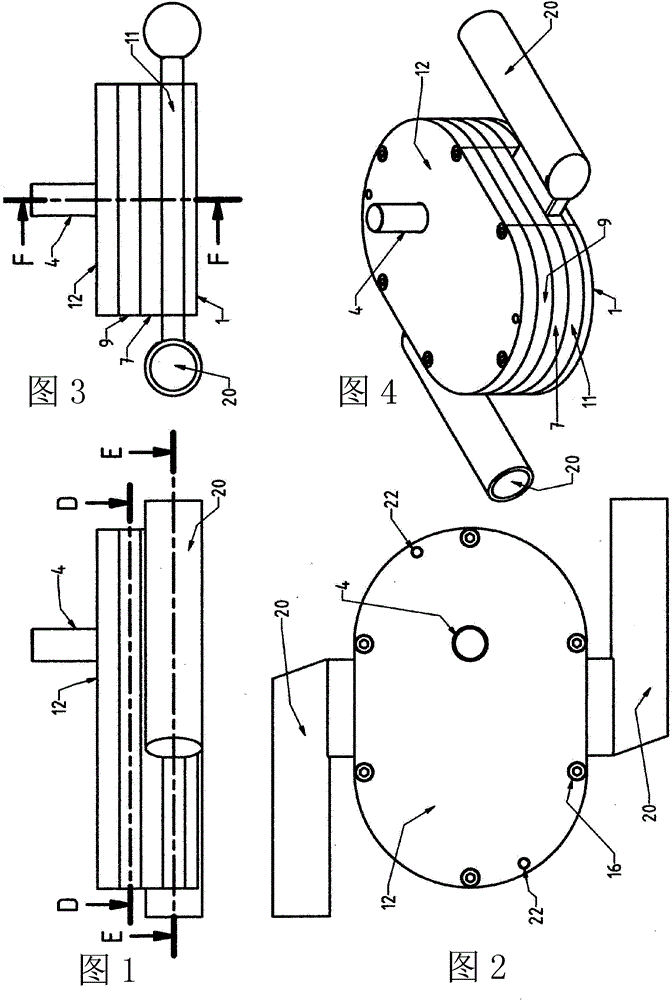

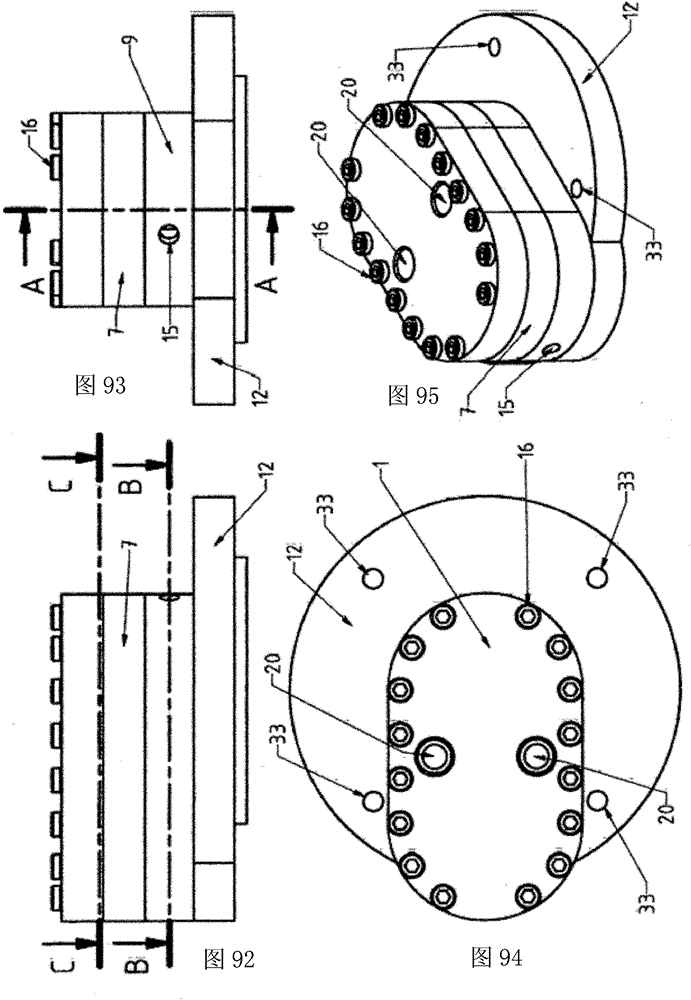

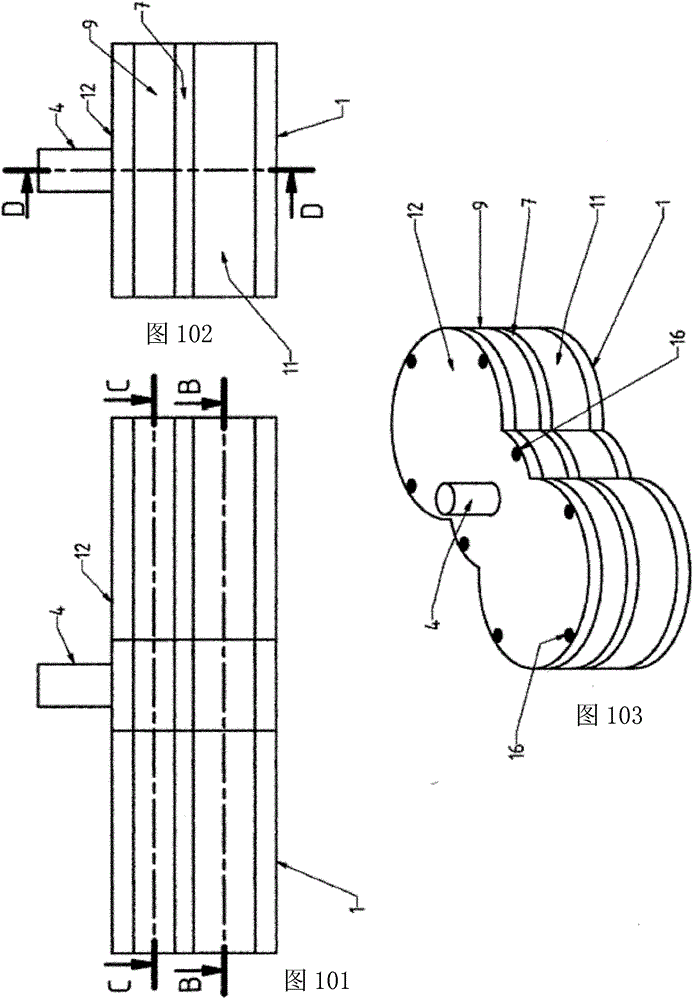

[0210] Figures 138 to 174 ,as well as Figures 1 to 137 The device in is described: a rotary piston with a cylindrical-semi-cylindrical body 6, which is integrated with the shaft, or has a hole in the center which is suitable for the diameter of the shaft, with separate or combined ( working) protrusions (A, B, C, D, E, F) or auxiliary grooves (G, H).

[0211] The one and / or several working longitudinal projections on the body 6 of the rotary piston are cylindrical-semi-cylindrical or otherwise shaped and parallel to the axis of the body 6 of the rotary piston. For easy shape identification, each shape is identified by the letter "A", "B", "C", "D", "E" or "F".

[0212] The auxiliary longitudinal groove / grooves on the body 6 of the rotary piston are cylindrical-semi-cylindrical and parallel to the axis of the body 6 of the rotary piston. For ease of shape identification, each shape is designated with the letter "G" or "H".

[0213] - (A) is a cylindrical-semi-cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com