Automatic analyzer

An automatic analysis device and action technology, applied in measurement devices, analysis materials, biological material analysis, etc., can solve the problems of increased cost of reagent containers, large amount of bubbles, difficult high-speed processing, etc., and achieve high reliability and processing capacity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

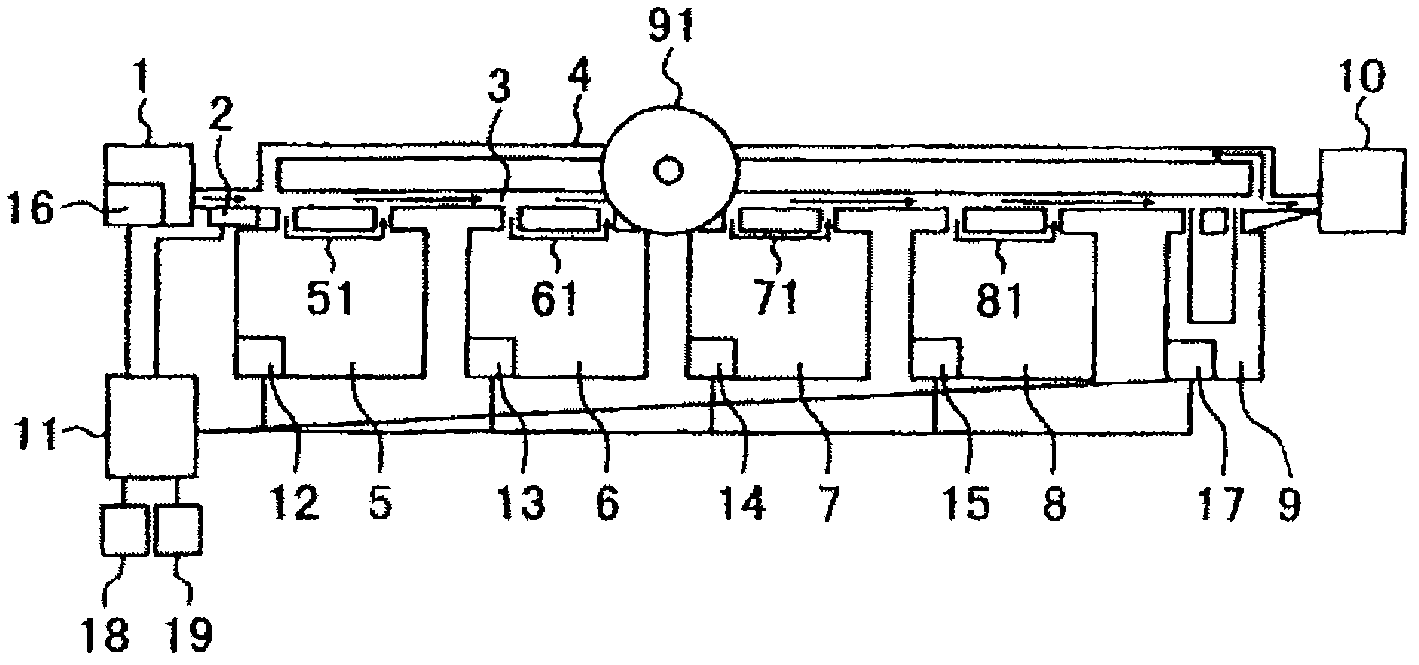

[0034] figure 1 It is a system block diagram showing the overall structure of the automatic analysis system to which the present invention is applied.

[0035] exist figure 1 Among them, the automatic analysis system includes: a sample rack feeding unit 1, an ID reading unit 2, a transport line 3 as a rack transport device, a transport line 4 for re-examination, analysis modules 5 to 8, a sample rack standby unit 9, and a testing unit. A frame collection unit 10 and a computer 11 for overall management.

[0036] The sample rack delivery unit 11 is a part for delivering a plurality of sample racks storing a plurality of samples (samples). The analysis modules 5 to 8 are arranged along the rack transport line 3 and connected to the transport line 3 in a detachable manner. The number of analysis modules can be arbitrary, in figure 1 Four in the example shown.

[0037] In addition, in figure 1 In the example shown, the analysis module is shown as a biochemical analysis modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com