Optical member for photomask and method for manufacturing the optical member

A technology of optical components and manufacturing methods, applied to optics, manufacturing tools, glass manufacturing equipment, etc., can solve problems that cannot be said to be sufficient transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

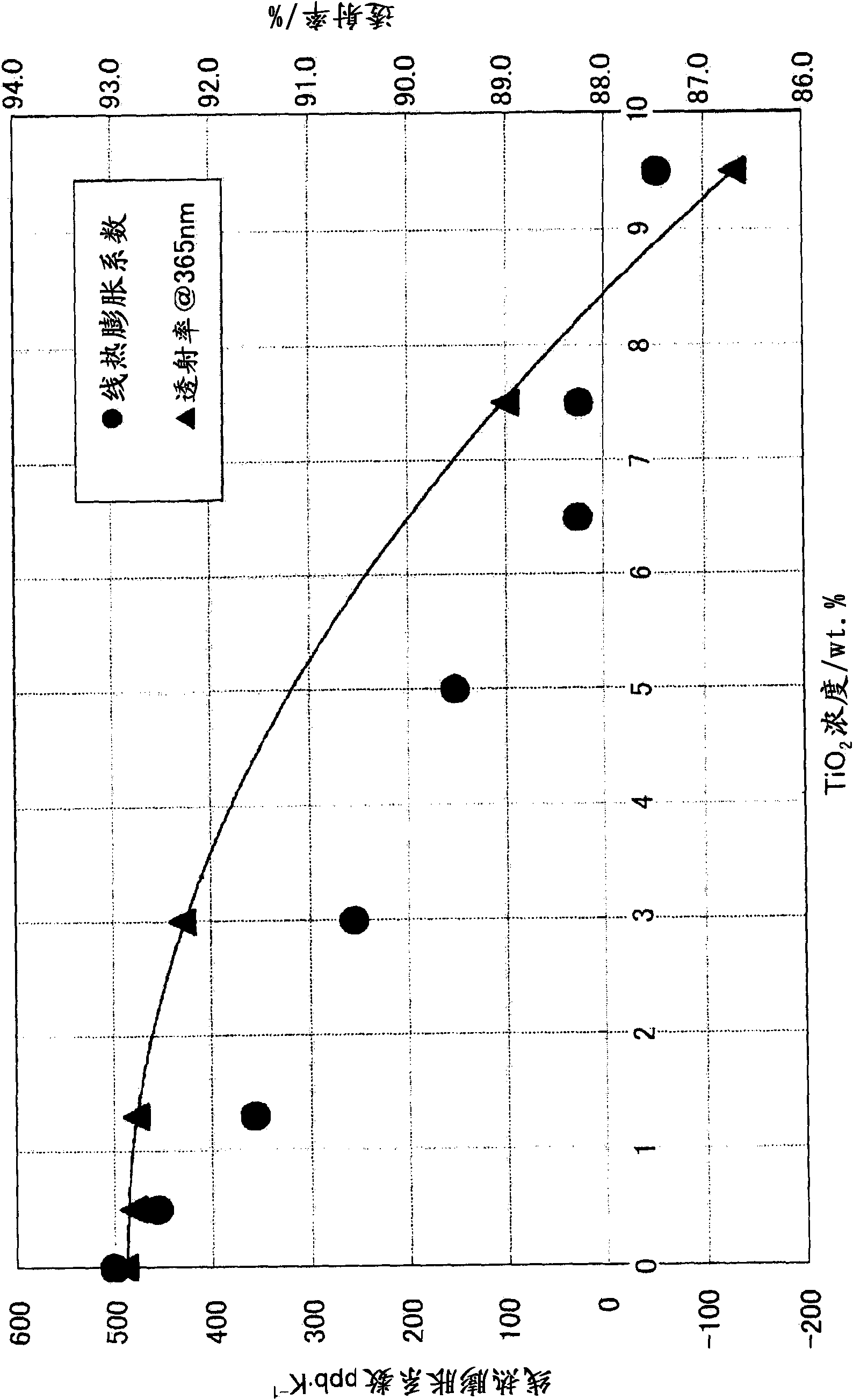

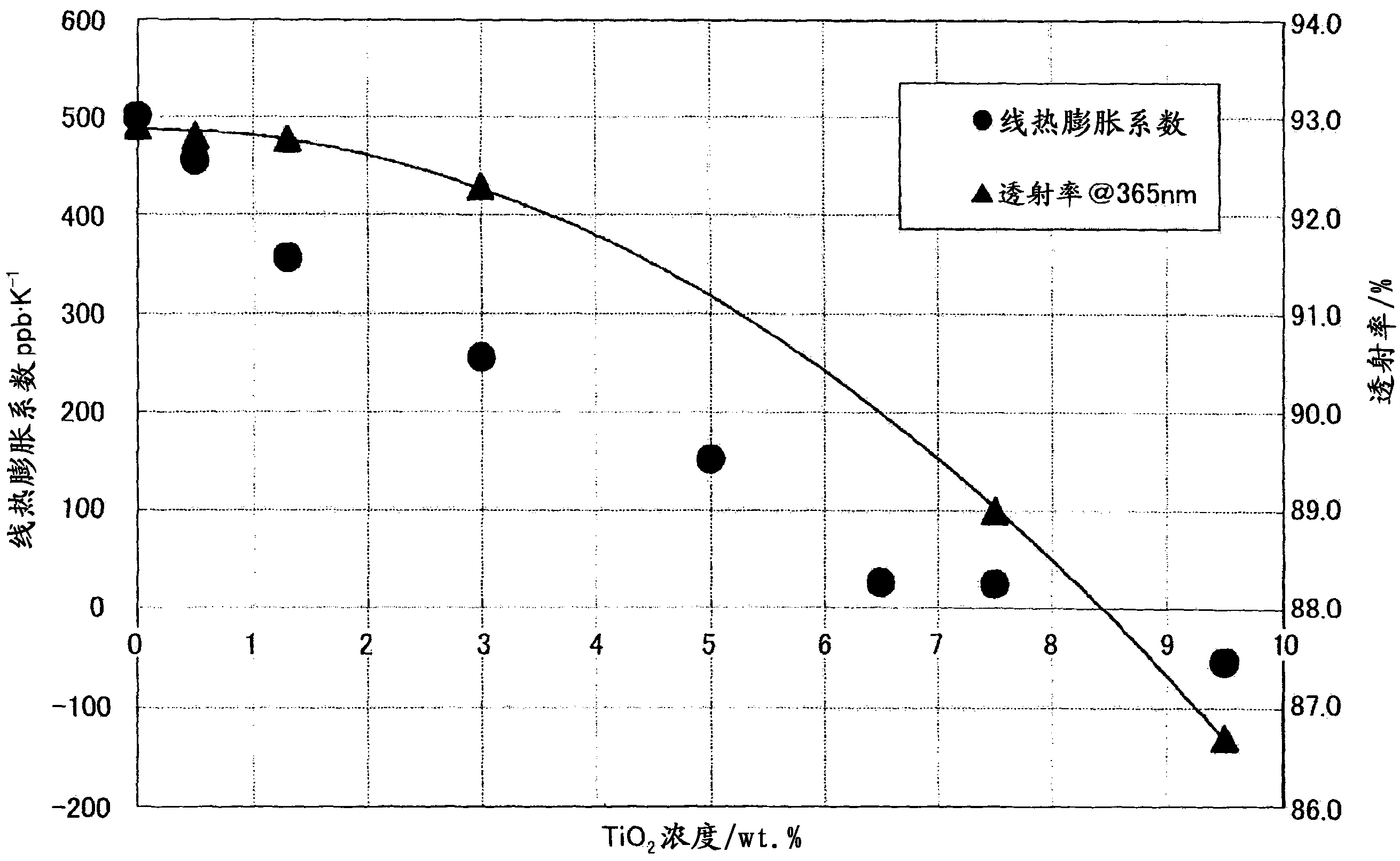

[0018] Embodiments of the optical member of the present invention will be described. The optical member of this embodiment is made of synthetic quartz glass (SiO 2 ) added 3.0 to 6.5% by weight of TiO 2 The resulting optical member can be in any shape. It is desirable that the optical member does not contain TiO 2 with SiO 2 other substances. For example, even when elements such as Al, Cu, Fe, Na, and K are contained as impurities, it is preferable that, for example, Al is 0.1 wt.ppm or less, Cu is 0.05 wt.ppm or less, and Fe is 0.1 wt.ppm or less, Na is 0.05 wt·ppm or less, and K is 0.05 wt·ppm or less.

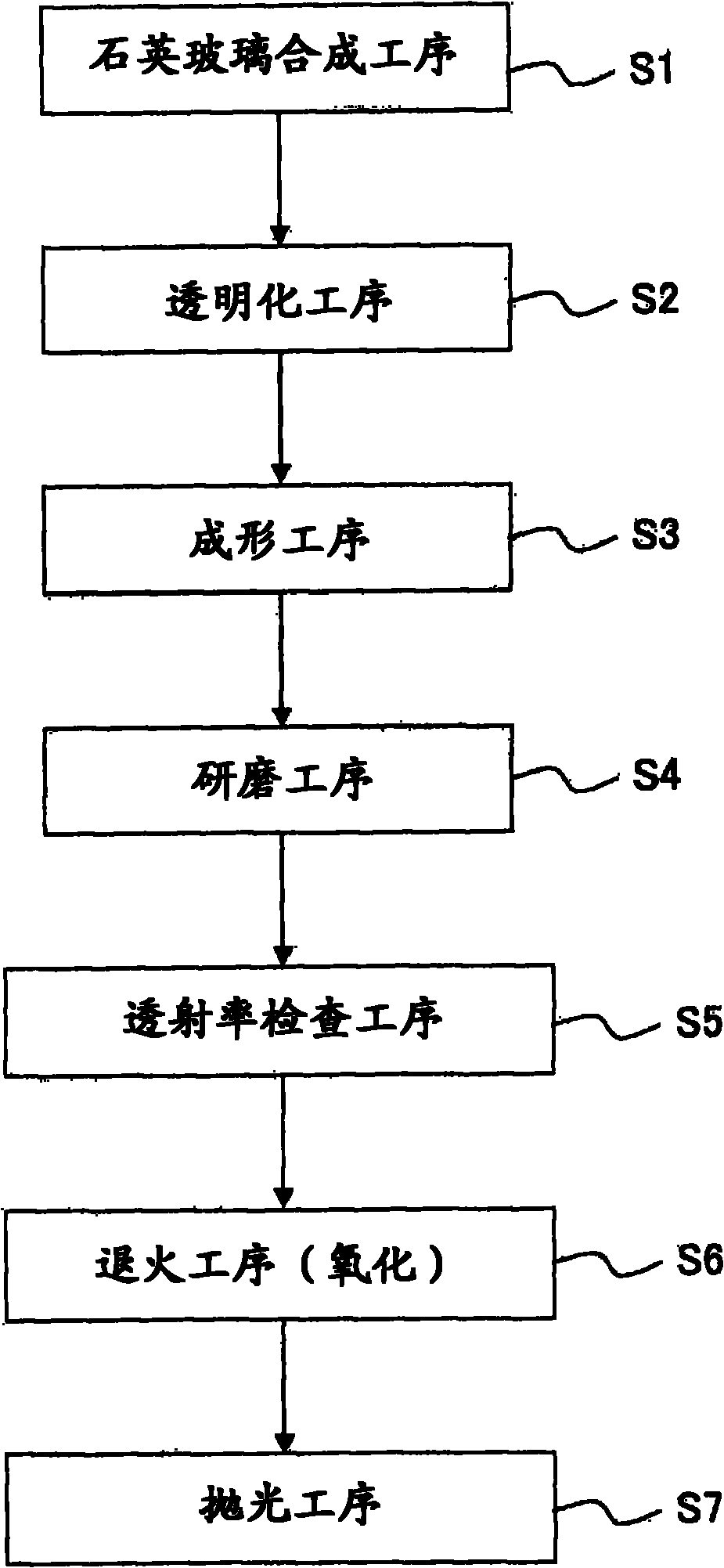

[0019] A method for producing the glass material of this embodiment will be described. First, in the synthesis furnace modulated by SiO 2 Particles and TiO 2 A stacked intermediate (soot body) composed of a mixture of particles. The soot body is an aggregate of fine particles, and a method of making the aggregate transparent by heating the aggregate to a glass trans...

Embodiment approach 2

[0030] In this embodiment, the improvement method of the manufacturing method of the optical member for photomasks demonstrated in Embodiment 1 is demonstrated. As mentioned above, by containing TiO 2 When quartz glass with a smaller expansion coefficient is used as an optical member for a photomask, TiO is preferable. 2 Resulting in less internal absorption. When using a material with a lot of internal absorption as an optical member for a photomask, in order to prevent the absorbed exposure light from increasing the temperature of the photomask or from irradiating the wafer due to a decrease in the transmittance of the photomask The reduction of the exposure light requires countermeasures such as increasing the power of the exposure light on the light source side, so it is different from that not containing TiO 2 Compared to quartz glass, it is desirable to increase the internal absorption of the material with as little as possible. The present inventors, as described in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com