Method for mounting a bush around a part of a shaft by means of a tight fitting

A one-part and bushing technology, which is applied to the rigid support of bearing components, bearings, couplings, etc., can solve the problems of difficult mass production and high cost, and achieve the effect of saving time and benefiting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

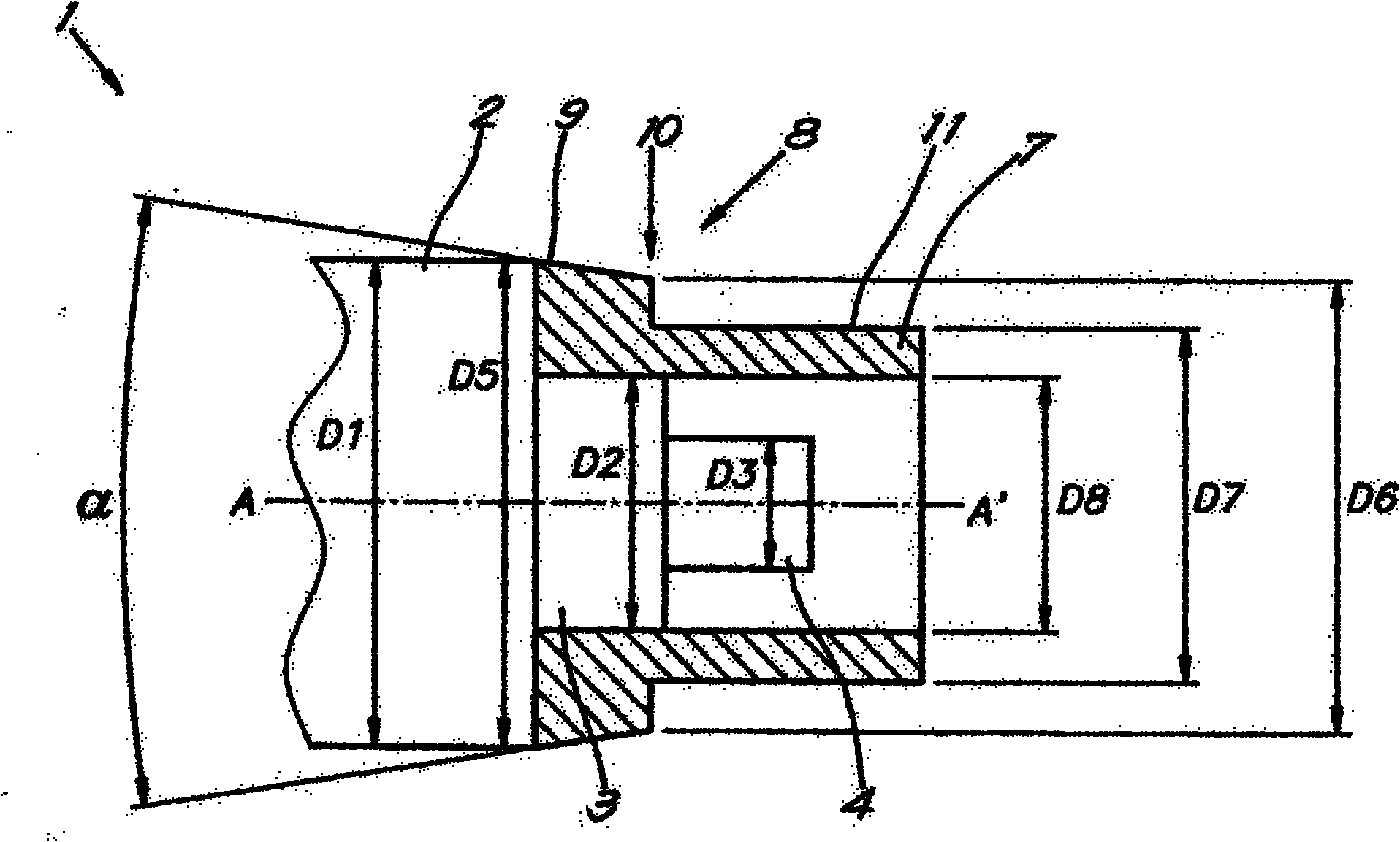

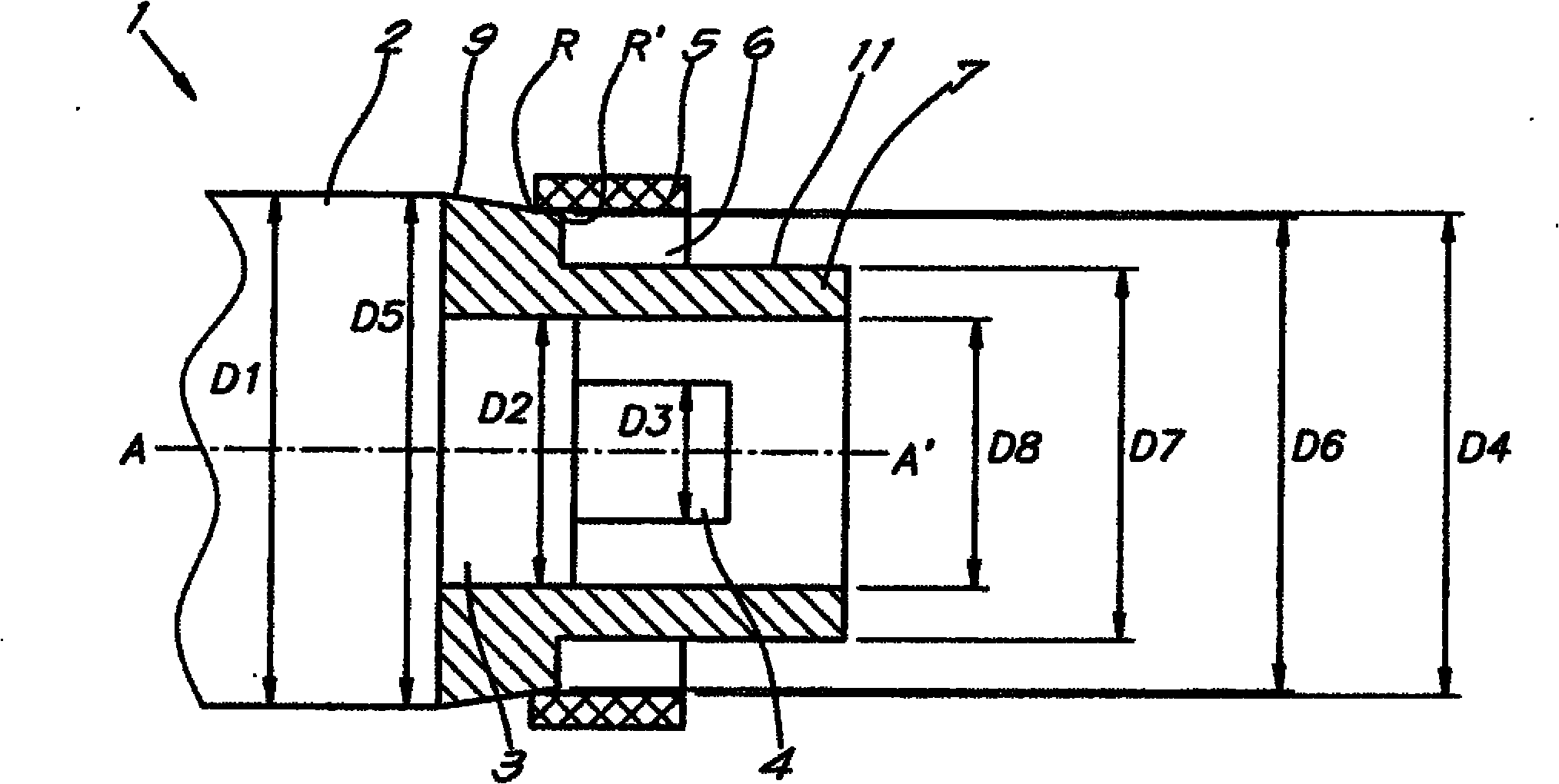

[0062] The present invention relates to a method of installing a bushing on a portion of a shaft using an interference fit.

[0063] figure 1 denotes a portion of one distal end of a stepped cylindrical shaft 1, and in this case according to the reduced shaft thickness here, the shaft 1 amounts to at least three cylindrical portions 2, 3 and 4, whereby each of the shaft 1 Sections 2 to 4 have their own diameters, ie from largest to smallest respective diameters D1 , D2 and D3 .

[0064] Such a shaft 1 is only an example of a shaft involved in the method according to the invention, and it may for example be a rotor shaft of a generator, on which permanent magnets are provided and on which a bushing must be provided to Protection such as magnets.

[0065] In another application, the shaft 1 must be, for example, the shaft of an engine, on which a flywheel is provided in order to allow a more stable operation of the motor shaft.

[0066] Of course, many other uses are not exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com