Chilli sauce and making process thereof

A production process, technology of chili sauce, applied in the direction of food preparation, application, food science, etc., can solve the problem of non-standard products, and achieve the effect of low cost, good taste and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Yak Beef Flavored Chili Sauce

[0023] Formula: 16% pepper, 47.9% rapeseed oil, 16% garlic, 16% dried yak meat, 1.6% ginger, 1.6% chili pepper, 0.15% piyazi, 0.75% edible salt;

[0024] Ingredients: 20 kg of pepper, 60 kg of rapeseed oil, 20 kg of garlic, 20 kg of dried yak meat, 2 kg of ginger, 2 kg of Chaotian pepper, 0.2 kg of Piyazi, 1 kg of edible salt;

[0025] Such as figure 1 Shown, the chili sauce of above-mentioned formula, its manufacture process is as follows:

[0026] (1) Weigh the ingredients according to the formula of the claim;

[0027] (2) Then select the peppers, dry the peppers, pull out the seeds of the dried peppers, wash and crush them;

[0028] (3) Mix the peppers in the above step (2) with the rest of the weighed ingredients, splash the oil, and sterilize by X-ray;

[0029] (4) After filling the ingredients in the above step (3), carry out secondary sterilization.

[0030] The degree of crushing in the step (2) is 0.3 mm in diameter.

[00...

Embodiment 2

[0036] Garlic Spicy Chilli Sauce

[0037] Formula: 16% pepper, 47.9% rapeseed oil, 16% garlic, 16% dried yak meat, 1.6% ginger, 1.6% chili pepper, 0.15% piyazi, 0.75% edible salt;

[0038] Ingredients: 20 kg pepper, 50 kg rapeseed oil, 20 kg garlic, 3 kg ginger, 1.5 kg salt, 0.1 kg pepper, 2 kg ginger, 4 kg Chaotian pepper, 2 kg Piyazi;

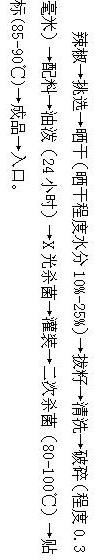

[0039] Pepper→picking→drying→pulling seeds→cleaning→crushing→ingredients→oil splashing→X-ray sterilization→filling→secondary sterilization (80°C-100°C)→labeling (85-90°C)→finished product→import.

[0040] This recipe is the same as that of yak chili sauce, and the yak meat-flavored chili sauce can be mixed with yak meat on the original recipe.

[0041] Ingredients: Ingredients: 20kg pepper, 60kg rapeseed oil, 20kg garlic, 20kg yak jerky, 2kg ginger, 2kg chaotian pepper, 0.2kg Piyazi, 1kg edible salt

[0042] Formula: 16% pepper, 47.9% rapeseed oil, 16% garlic, 16% dried yak meat, 1.6% ginger, 1.6% pepper, 0.15% piyazi, 0.75% edible salt.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com