Preparation technology of nano arsenic trioxide/poly (lactic-co-glycolic acid) coated bracket

A technology of lactic acid glycolic acid copolymer and lactic acid glycolic acid, applied in medical science, surgery, etc., can solve problems affecting the long-term efficacy of PTA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

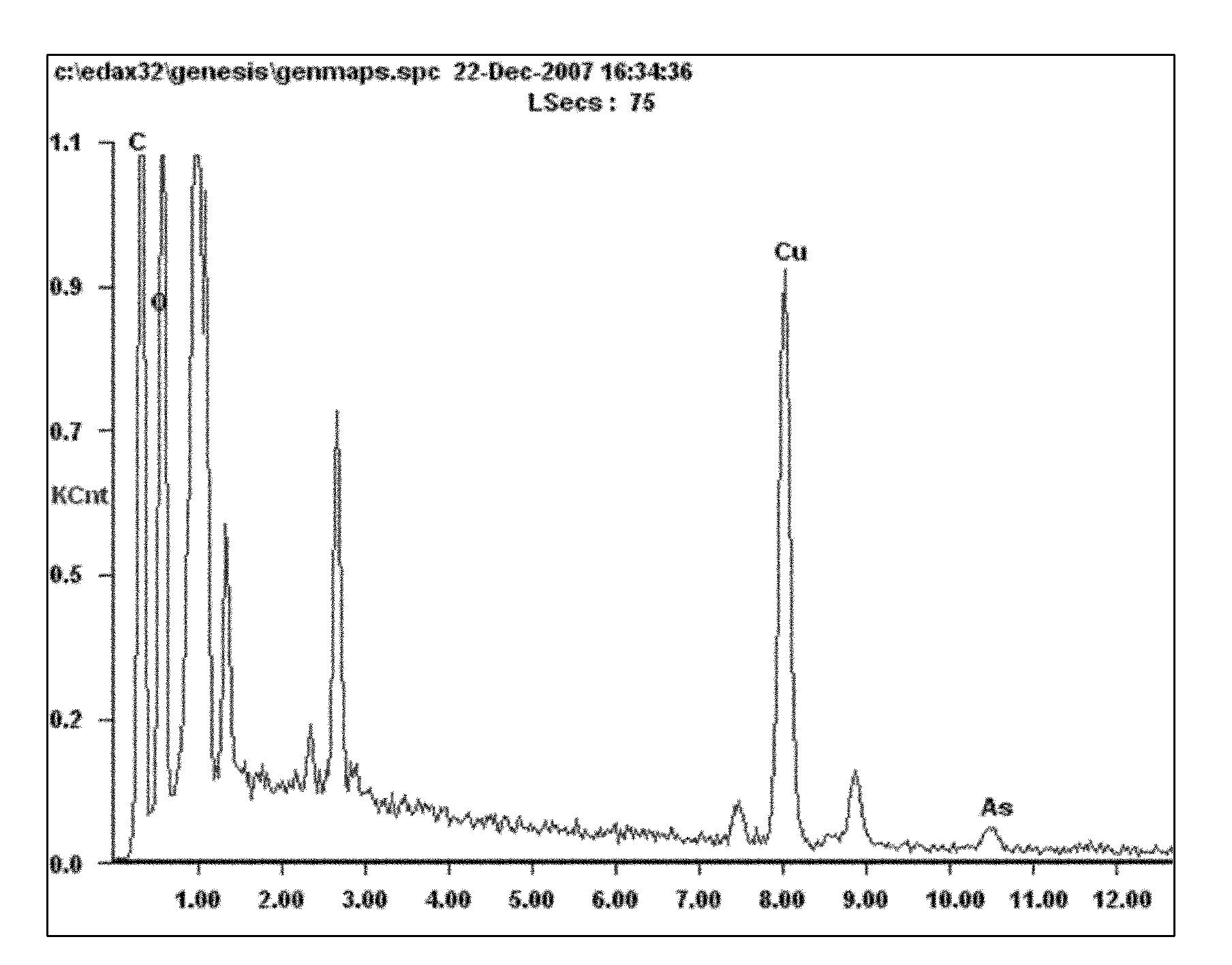

[0056] A nano-arsenic trioxide / lactide-glycolic acid copolymer coated stent comprises: a stent body, and the outside of the stent body is coated with nano-arsenic trioxide / lactide-glycolic acid copolymer.

Embodiment 2

[0058] A kind of preparation method of nano arsenic trioxide / lactic acid glycolic acid copolymer coating stent,

[0059] Preparation of step 1 nano arsenic trioxide / lactic acid glycolic acid copolymer:

[0060] Take 0.01-0.03g of arsenic trioxide powder and fully dissolve it in a sodium hydroxide solution with a molar concentration of 1mmol / L, and adjust the pH value to 7.2-7.4 with 1mmol / L hydrochloric acid to form a liquid;

[0061] Dissolve 100mg of lactic acid-glycolic acid copolymer in 2ml of dichloromethane to form liquid B;

[0062] Add liquid A into liquid B, wherein the volume ratio of liquid A to liquid B is 6-10:1, this embodiment can choose 6:1, 7:1 or 10:1, ultrasonic emulsification for 1 min to form liquid C;

[0063] Add 12ml of polyvinyl alcohol with a mass percentage concentration of 2.25% to 60-100ml of liquid C, use an ultrasonic generator to ultrasonicate liquid C for 90 seconds, disperse in ice water, and form liquid D, among which, the model of the ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com