Spinning method of variable diameter pipe dieless floating rolling ball and fixture

A technology of moldless floating ball spinning and variable diameter tubes, which is applied in the direction of manufacturing tools, feeding devices, positioning devices, etc., can solve the problem that ball spinning cannot meet the process requirements of variable inner diameter tubes, and achieve strong replaceability and work High efficiency and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

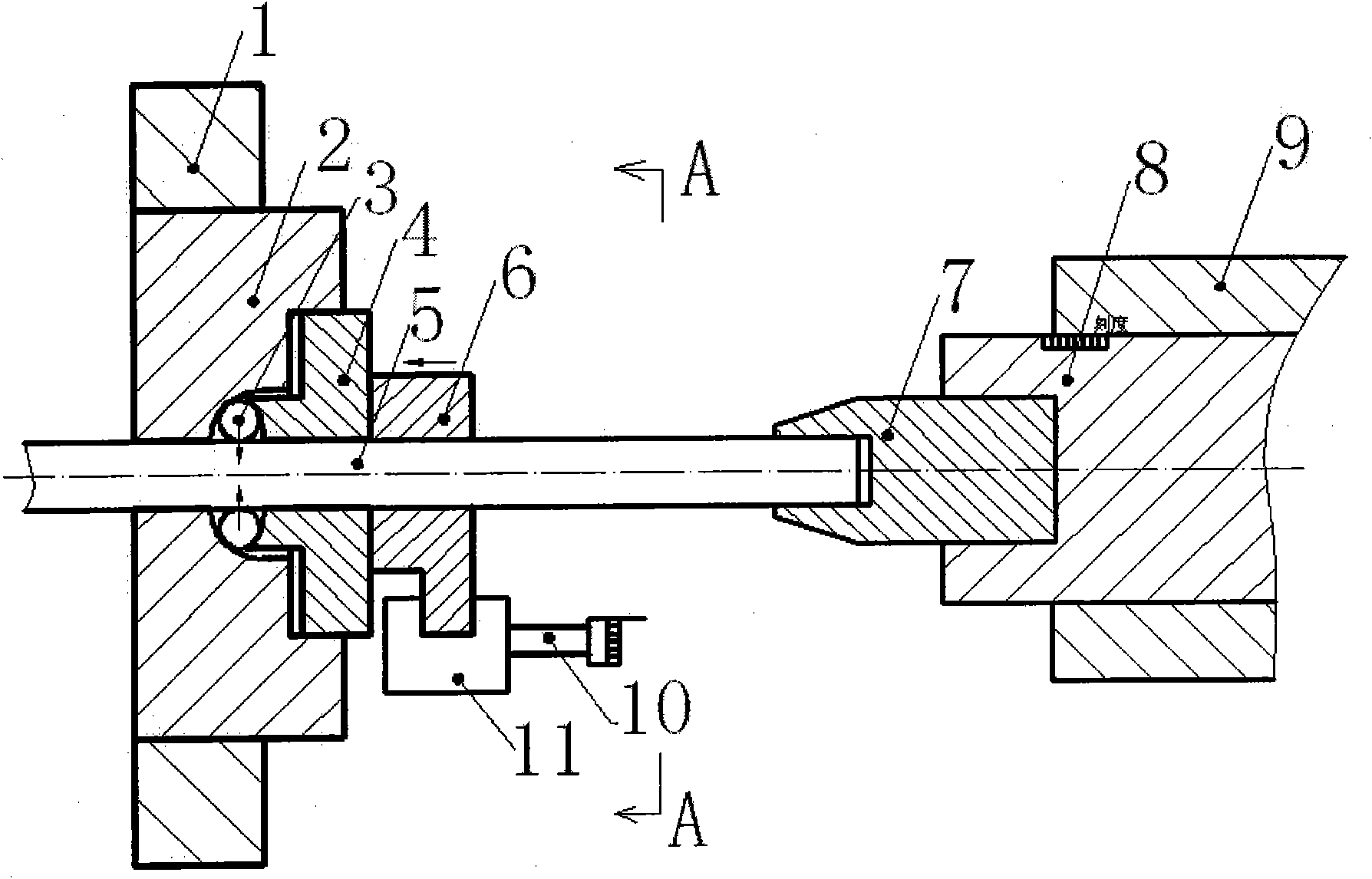

[0030] This embodiment is a dieless floating ball spinning method for a variable diameter tube, and its specific process is:

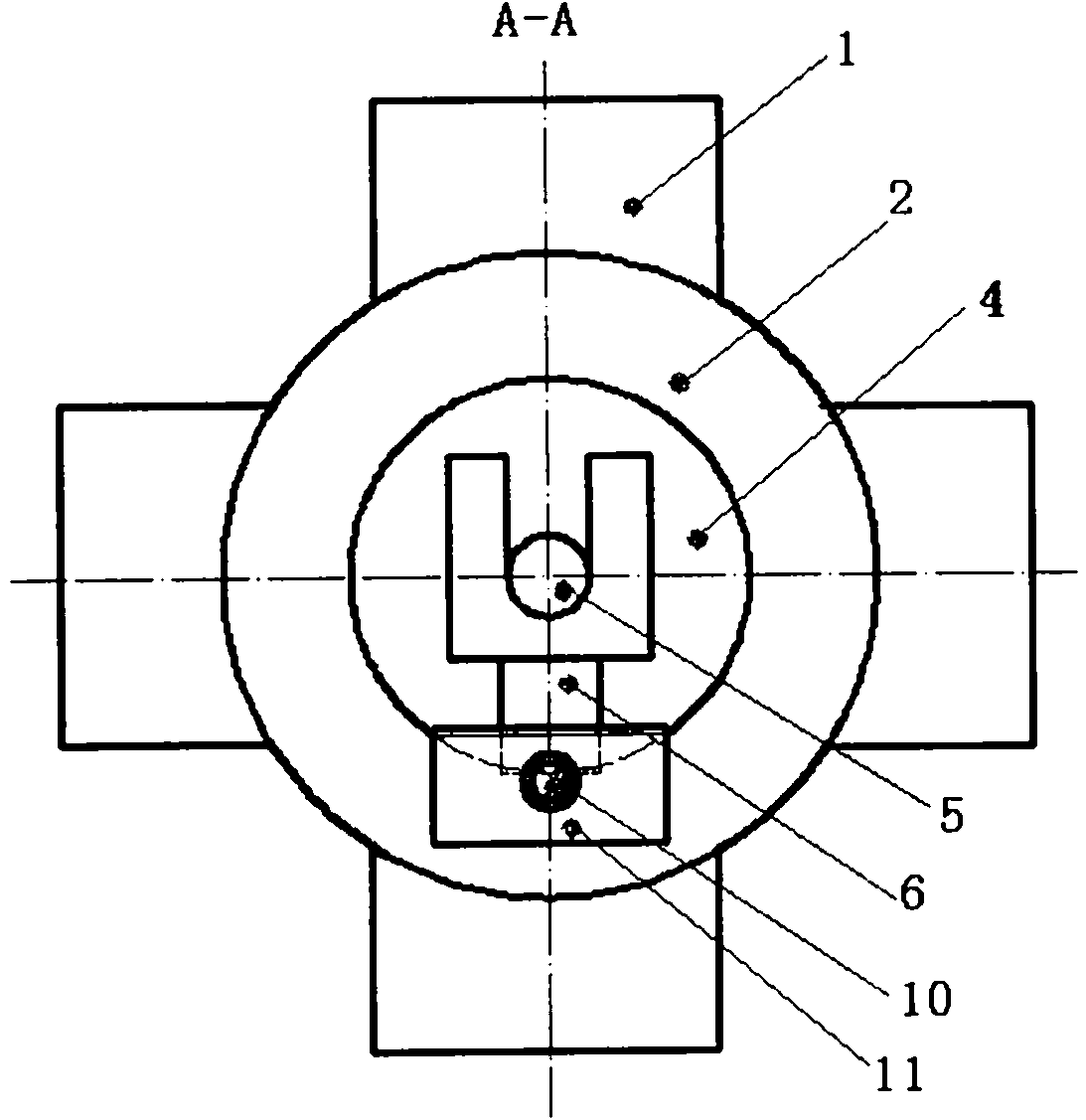

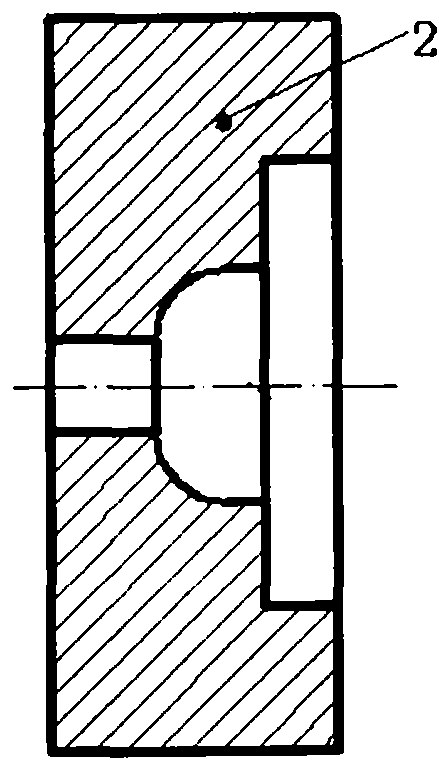

[0031] The first step is to install the spinning tooling. Apply lubricating oil in the groove of the die ring, select 7 φ8 balls, distribute them evenly in the groove of the die ring one by one, and seal the balls in the groove by pressing blocks. Pass one end of the tube blank through the inner hole of the spindle box main shaft, the center hole of the die ring and the pressing block, and the U-shaped groove of the fork push rod, and tighten the tube blank with the chuck, which is fixed on the sleeve; through the control of the small The number of grids on the dial on the supporting plate determines the axial movement distance of the fork-shaped push rod, and the fork-shaped push rod further pushes the pressing block to move. When the right end face of the pressing block is 5.2mm from the end face of the die ring, the pressing block presses the tube b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com