Two-degree-of-freedom dynamic error counteracting device for free-form surface ultra-precision turning

A technology of dynamic error and degrees of freedom, applied in turning equipment, auxiliary devices, accessories of toolholders, etc., can solve the problem that multi-axis motion servo device does not meet the performance requirements of free-form surface ultra-precision turning dynamic error cancellation device, etc. Easy-to-control implementation, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

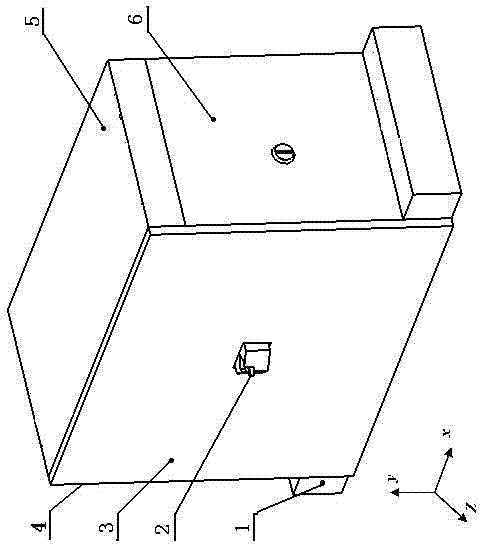

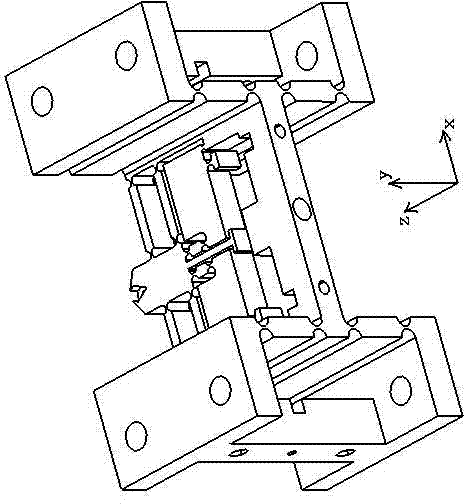

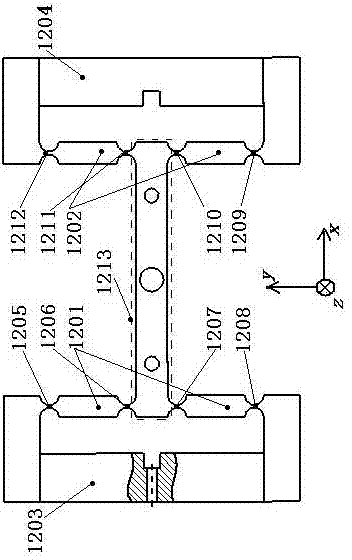

[0021] The left side panel 4, the right side panel 6 and the front cover 3 are fixedly connected with the base 1 and the upper cover 5 respectively, and the two-degree-of-freedom flexible hinge mechanism 12 is positioned and fixedly connected with the base 1 by bolts, The surfaces 101, 102, and 103 are positioned, the diamond tool 2 is fixedly connected to the two-degree-of-freedom flexible hinge mechanism 12, and the X-direction piezoelectric actuator 11 is respectively connected to the left column 1203 in the two-degree-of-freedom flexible hinge mechanism 12 through the X-direction U-shaped block 10. 1. The U-shaped groove on the right column 1204 is fixedly connected with the X-direction pre-tightening screw 9; the Z-direction piezoelectric actuator 13 and the Z-direction piezoelectric actuator 17 respectively pass through the Z-direction U-shaped block 14 and the Z-direction U Type block two 18, and the two U-shaped grooves at the rear of the X-direction motion platform 121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com