Process for manufacturing press-forming mould for simultaneously manufacturing a plurality of parts

A press forming and process technology, which is applied in the field of press forming mold manufacturing process, can solve problems such as difficulty in guaranteeing coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

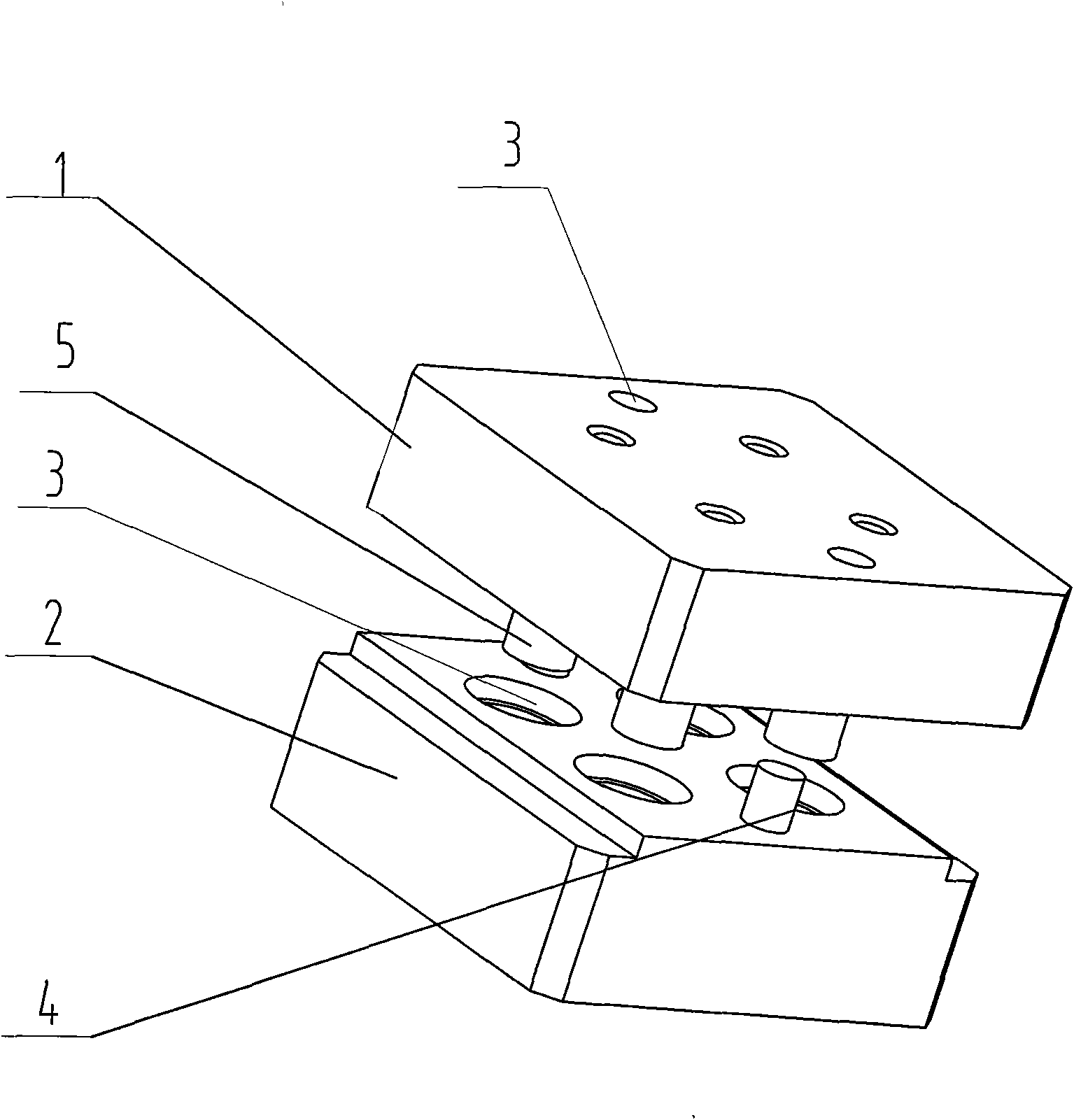

[0019] like figure 1 Shown is a press-forming mold for multiple parts. The mold includes an upper mold 1, a lower mold 2, a guide post 4, and a mandrel 5. The upper mold and the lower mold are respectively provided with a plurality of mold cavities 3.

[0020] manufacture figure 1 The mold shown, its steps are as follows:

[0021] 1. Process the upper and lower templates to ensure the parallelism of the upper and lower templates. The upper and lower templates are welded together by spot welding, and the center holes of each cavity are drilled on the upper surface of the upper template, and the guide post holes are drilled into through holes;

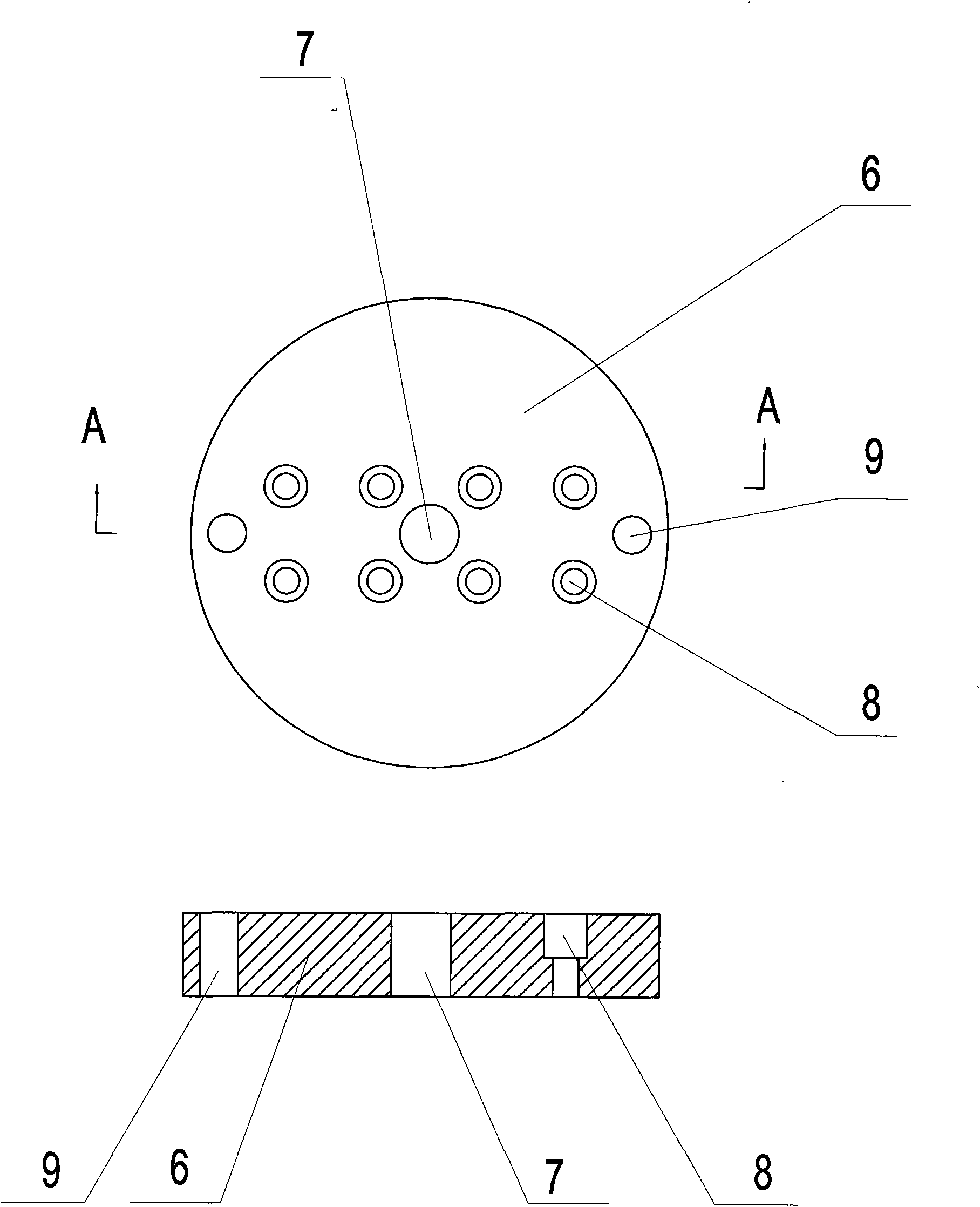

[0022] 2. Manufacturing tooling such as figure 2 As shown, the tooling is provided with a top through hole 8, a counterbore 9 and a machine tool puller fixing hole 7. During production, the size of the top through hole 8 should be larger than the size of the top of the machine tool. The size, quantity and position of the counterbore 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com