Eccentric expansion brick-jacking mould device of brick press

A brick press and eccentric technology, which is applied in the field of eccentric telescopic top brick mould devices of brick presses, can solve the problems of low processing accuracy, inability to maintain, waste of piston structure, etc., achieve smooth and accurate transmission, convenient disassembly and maintenance, The effect of low operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings, but it does not constitute any limitation to the present invention.

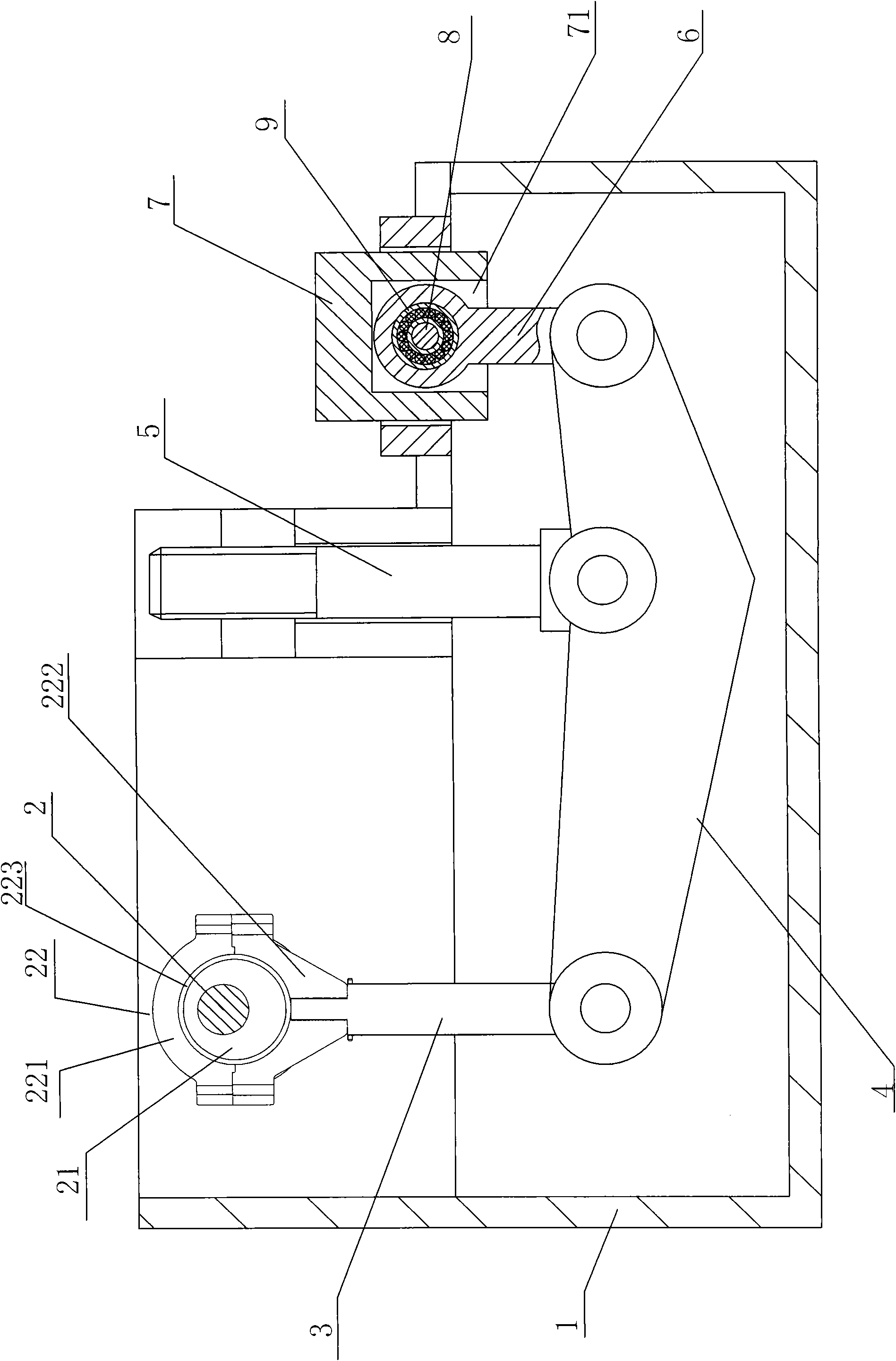

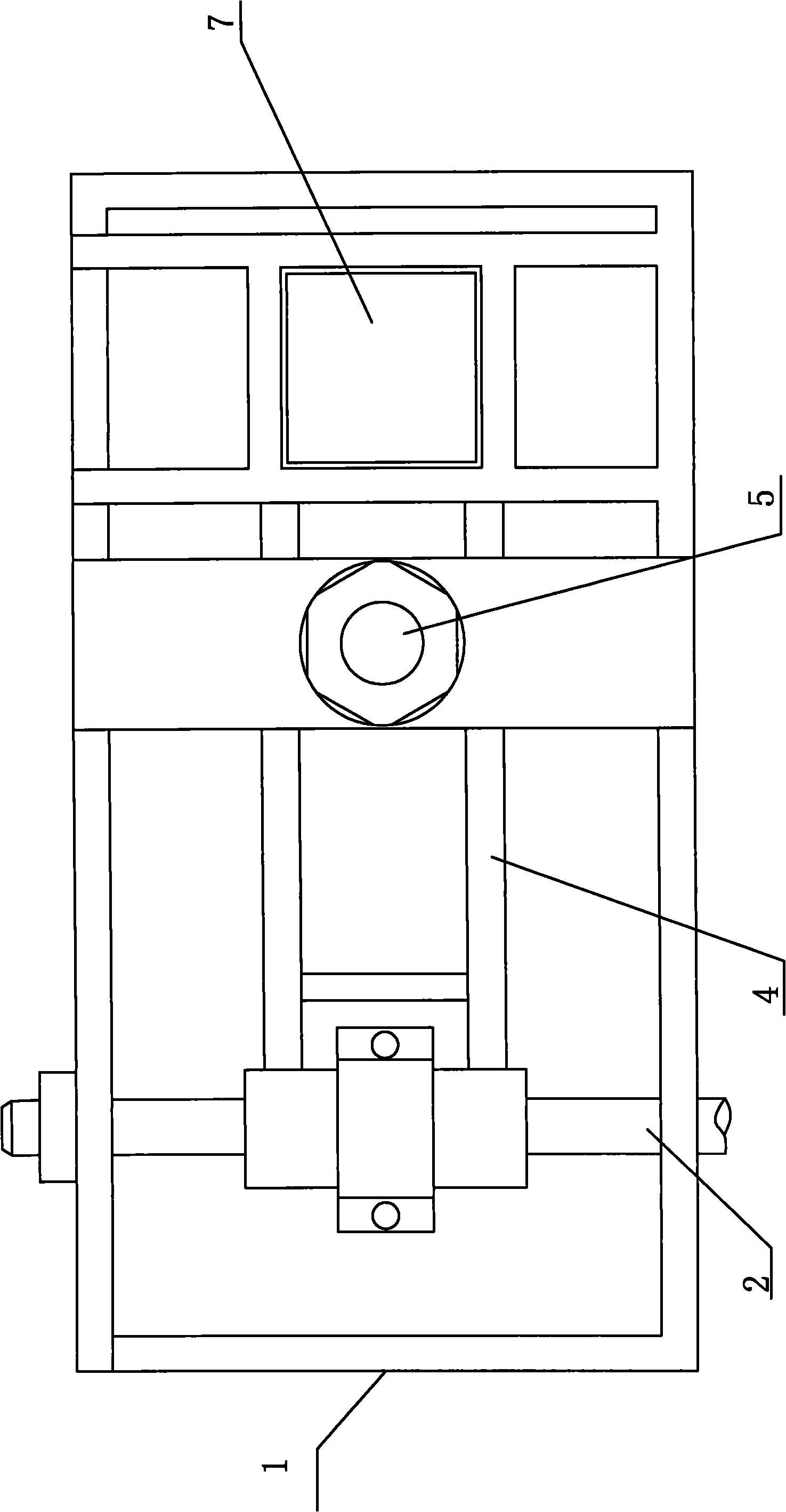

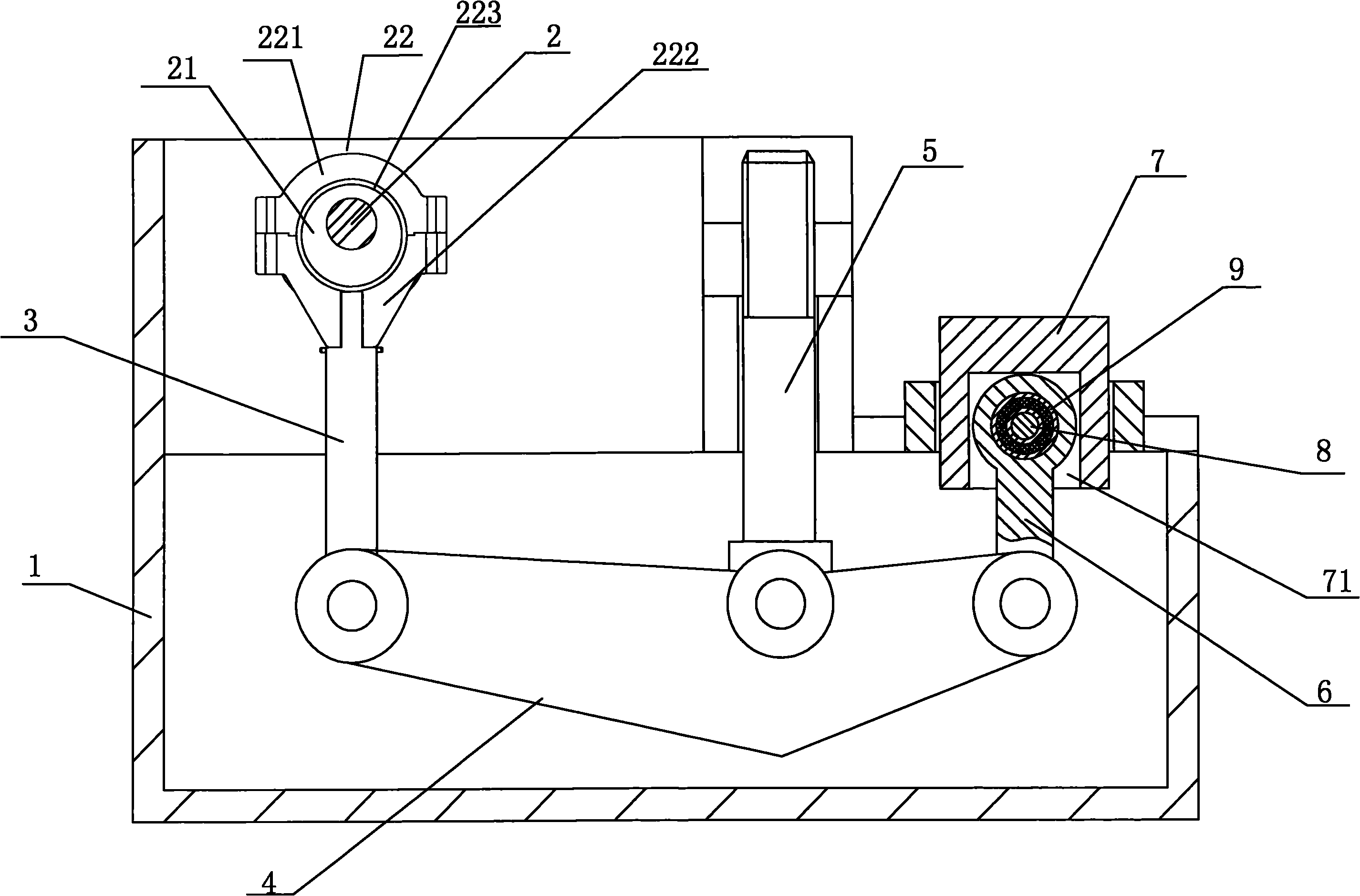

[0013] as attached figure 1 , figure 2 As shown in , an eccentric telescopic brick ejector mold device for a brick press is composed of a body 1, a horizontal main shaft 2, a connecting rod 3, a rocker 4, a fulcrum vertical shaft 5, a ejector rod 6 and a top pressing die 7, and the horizontal main shaft 4-axis linkage rotation power, the horizontal main shaft 2 is provided with an eccentric wheel 21, and the eccentric wheel 21 is sleeved with a rotating matching sleeve 22, the middle part of the rocker 4 is pinned and positioned by the fulcrum vertical shaft 5, and its front end is rotatably pinned with the ejector rod 6, The rear end is rotatably pinned with the lower end of the connecting rod 3, and the upper end of the connecting rod 3 is fixedly connected with the rotating matching sleeve 22.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com