Method for designing overheating prevention heat preserving water tank

A technology of thermal insulation water tank and design method, which is applied in heating methods, thermal insulation containers, lighting and heating equipment, etc., can solve the problems of high cost, waste of water resources, complicated system design, etc., and achieves low cost, avoidance of waste, and simple system design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the design method of a kind of anti-overheating heat preservation water tank of the present invention is given below in conjunction with accompanying drawing.

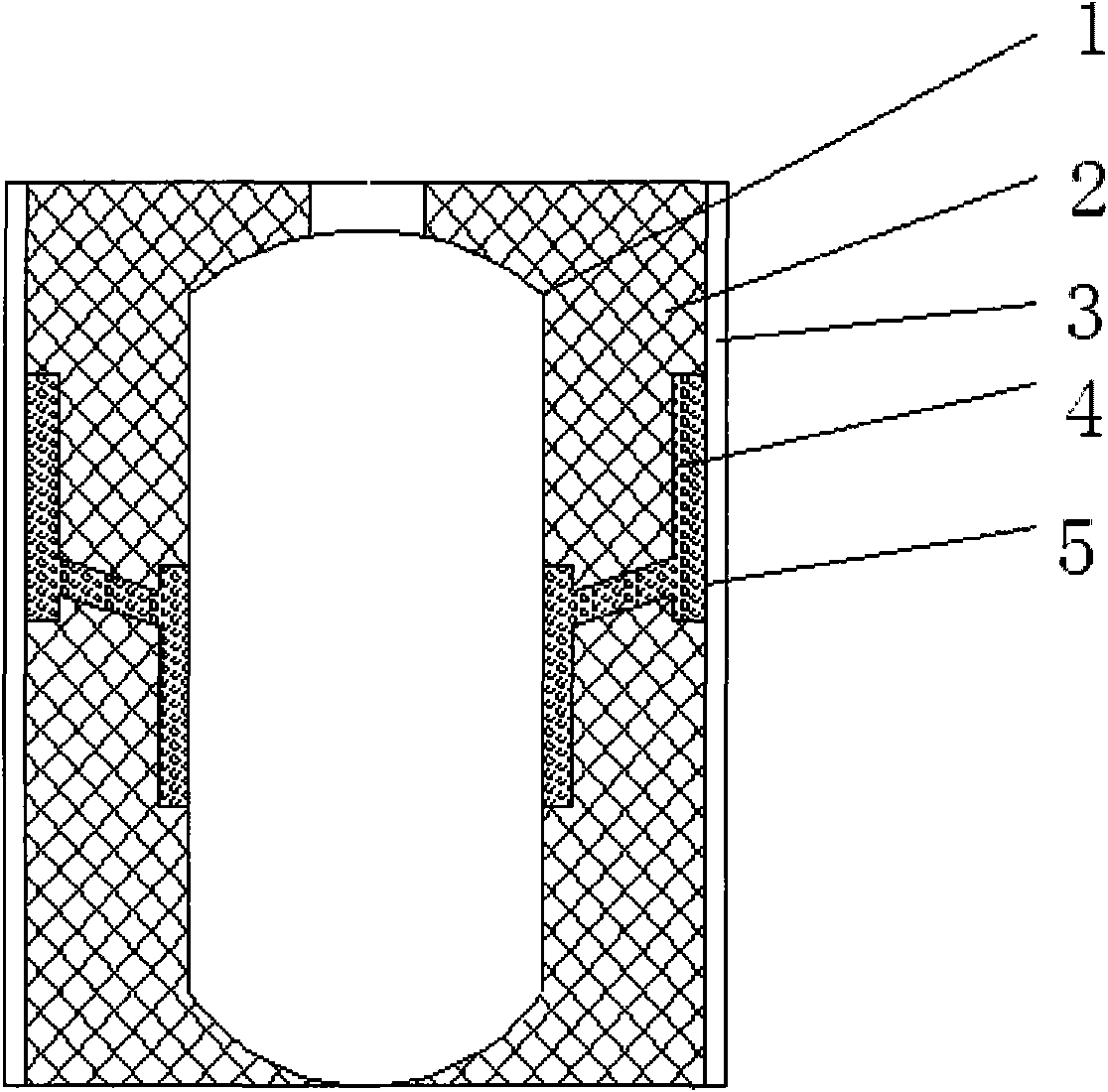

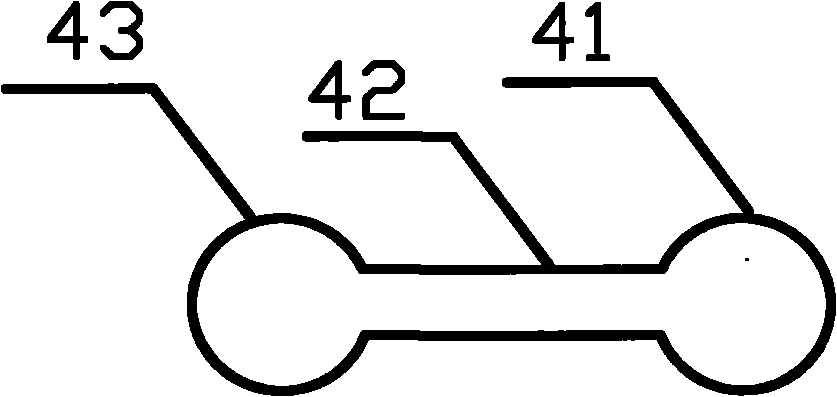

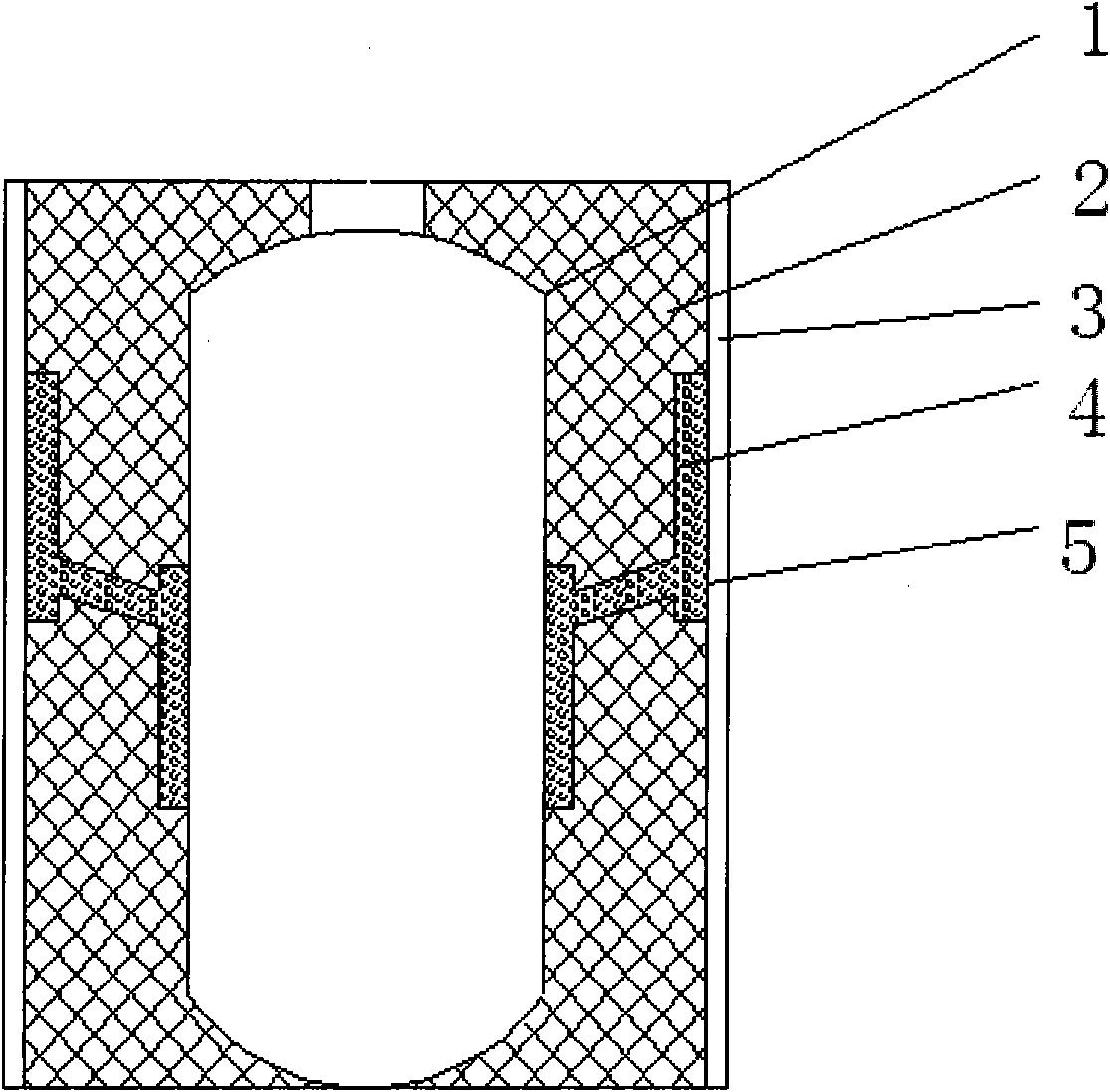

[0020] figure 1 It is a schematic diagram of an anti-overheating thermal insulation water tank, figure 2 For the top view of the thermal guide structure, please refer to figure 1 and figure 2 As described above, the present invention is an anti-overheating heat preservation water tank, comprising a water tank liner 1, an insulation layer 2 and a water tank skin 3, the water tank liner 1 is used for storing hot water, the water tank liner 1 is covered with an insulation layer 2, and two sets of heat preservation layers A water tank skin 3 is provided; wherein, a hollow thermal conduction device 4 is embedded in the insulation layer 2, and both sides of the thermal conduction device 4 are attached to the water tank liner 1 and the water tank skin 3 respectively, so that the water tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com