Small-sized wet spinning device

A wet-spinning, small-scale technology, which is applied in the field of spinning devices and small-scale wet-spinning devices, can solve the problems of inconvenient fiber spinning experiments in production-type spinning devices, and achieve the effect of increasing transmission power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

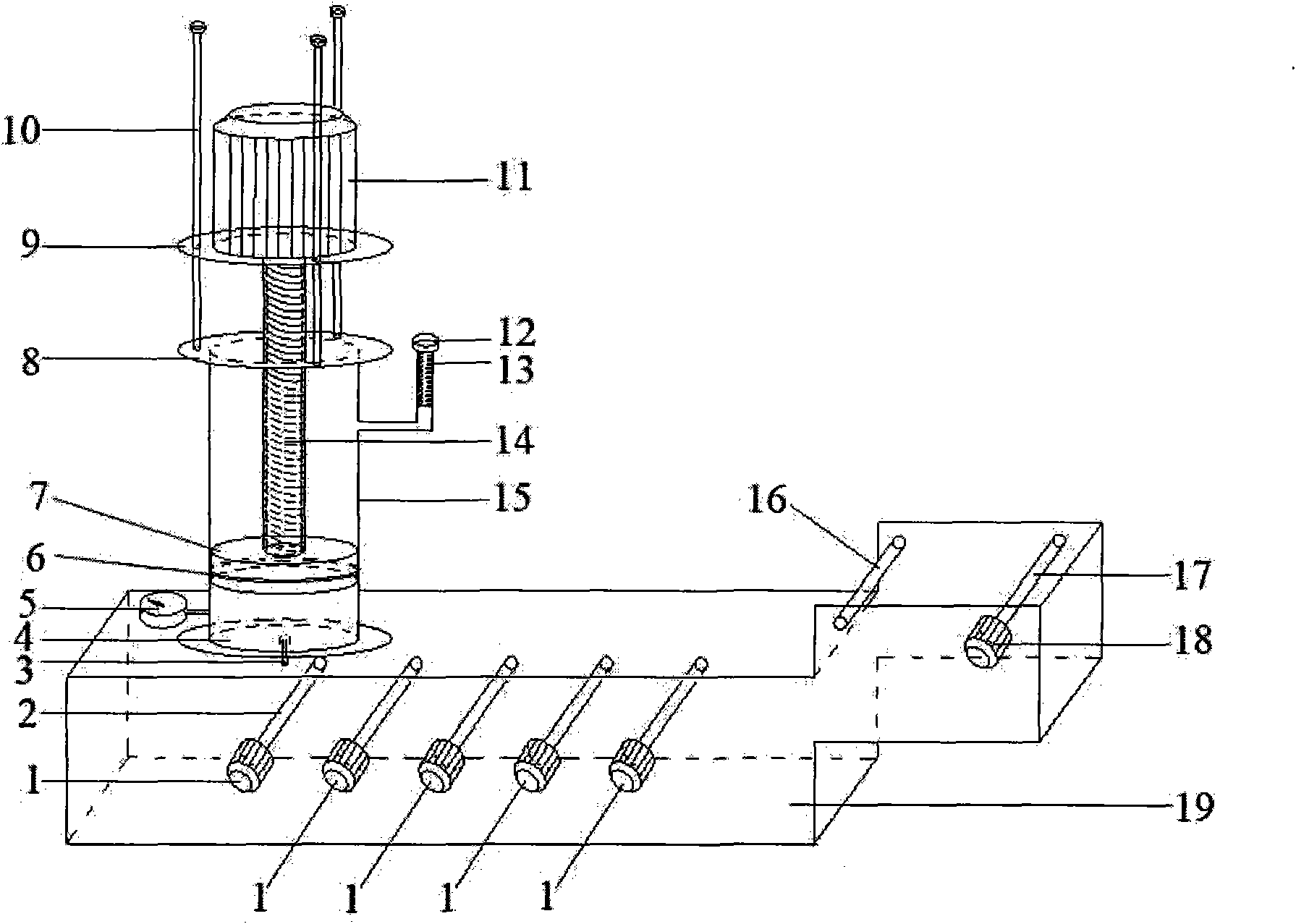

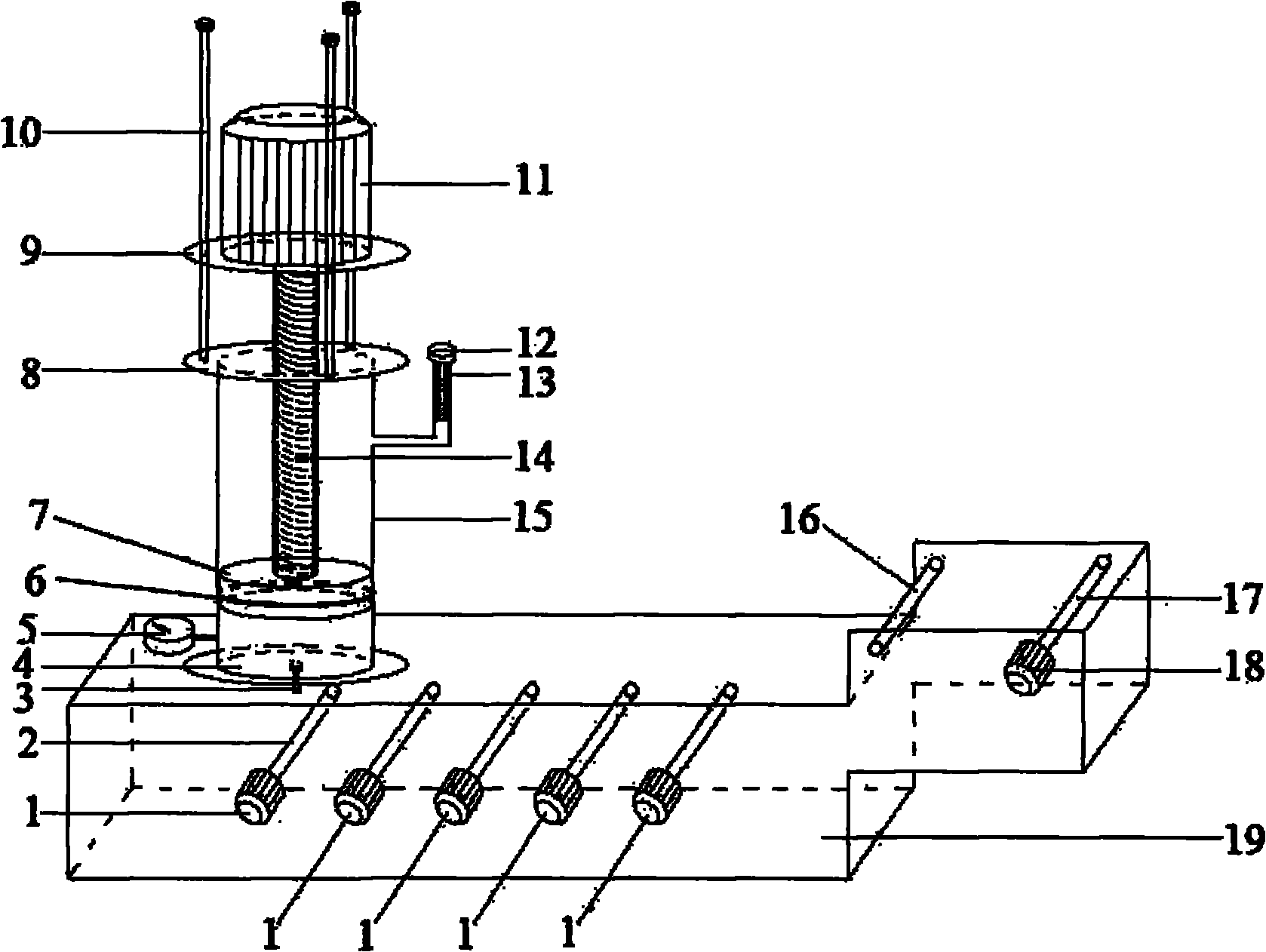

[0016] Such as figure 1 As shown, it includes a spinning dope delivery machine, a spinneret hole connected to the outlet of the spinning dope delivery machine, a coagulation bath and a winding roller, wherein the spinning dope delivery machine consists of a spinning solution cylinder 15, a piston 7, The screw rod 14 and the screw motor 11 are formed, the lower end of the screw rod 14 is fixedly connected with the piston 7, the piston ring 6 is arranged between the piston 7 and the inner wall of the spinneret liquid cylinder 15, the upper end of the spinneret liquid cylinder 15 is fixedly provided with a cylinder head 8, and the screw rod 14 passes through the screw thread The pair is connected with the cylinder head 8, the thread between the screw rod 14 and the cylinder head 8 of the spinneret liquid cylinder is a coarse thread, the upper end of the screw rod 14 is fixedly connected with the output shaft of the screw motor 11, and the lower end of the spinneret liquid cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com