Lifting installation method of integral bridge arch rib

An installation method and overall upgrading technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as complex stress, long construction period, and increased difficulty of bridge construction, and achieve the effect of reducing impact and construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

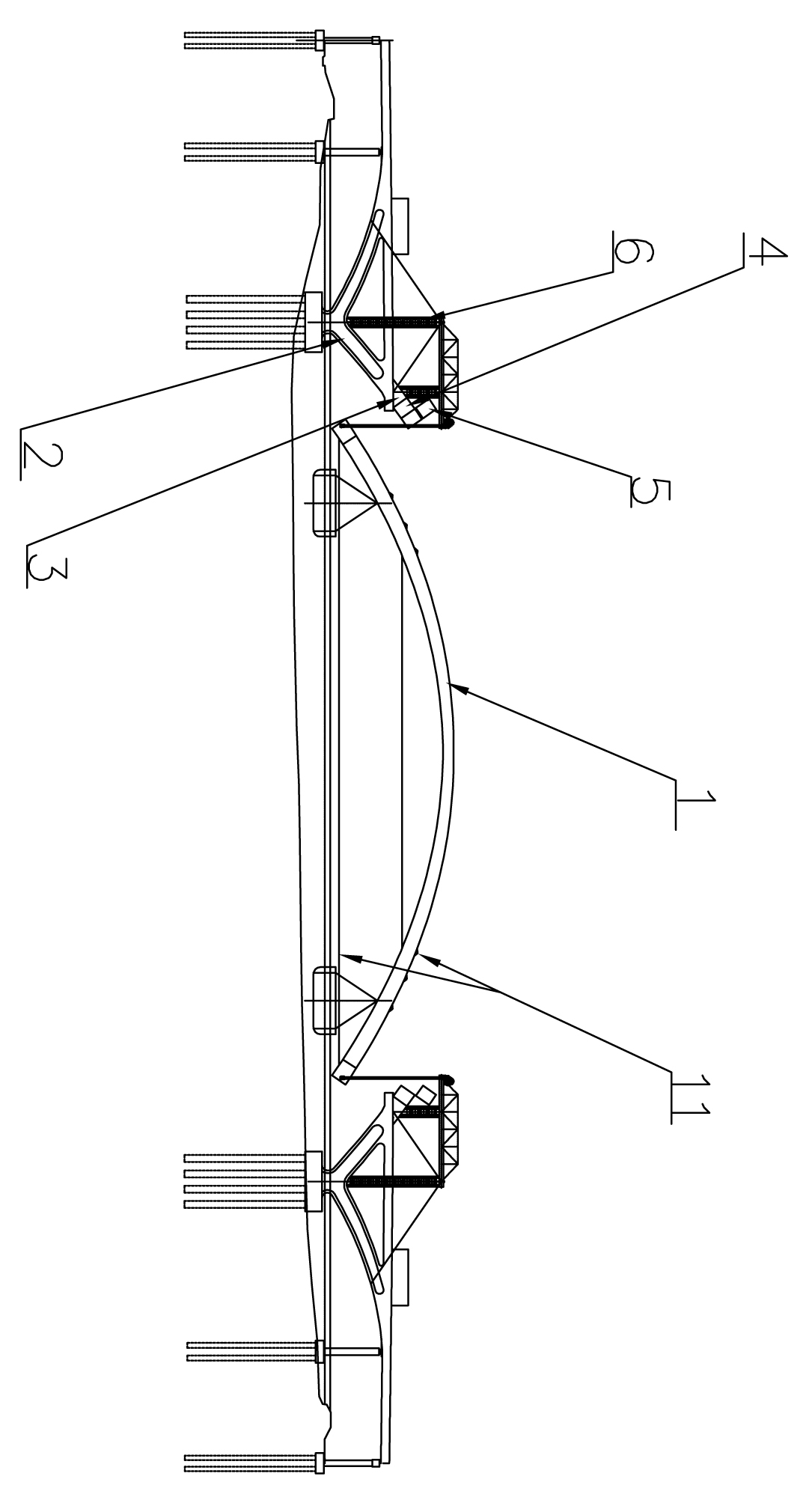

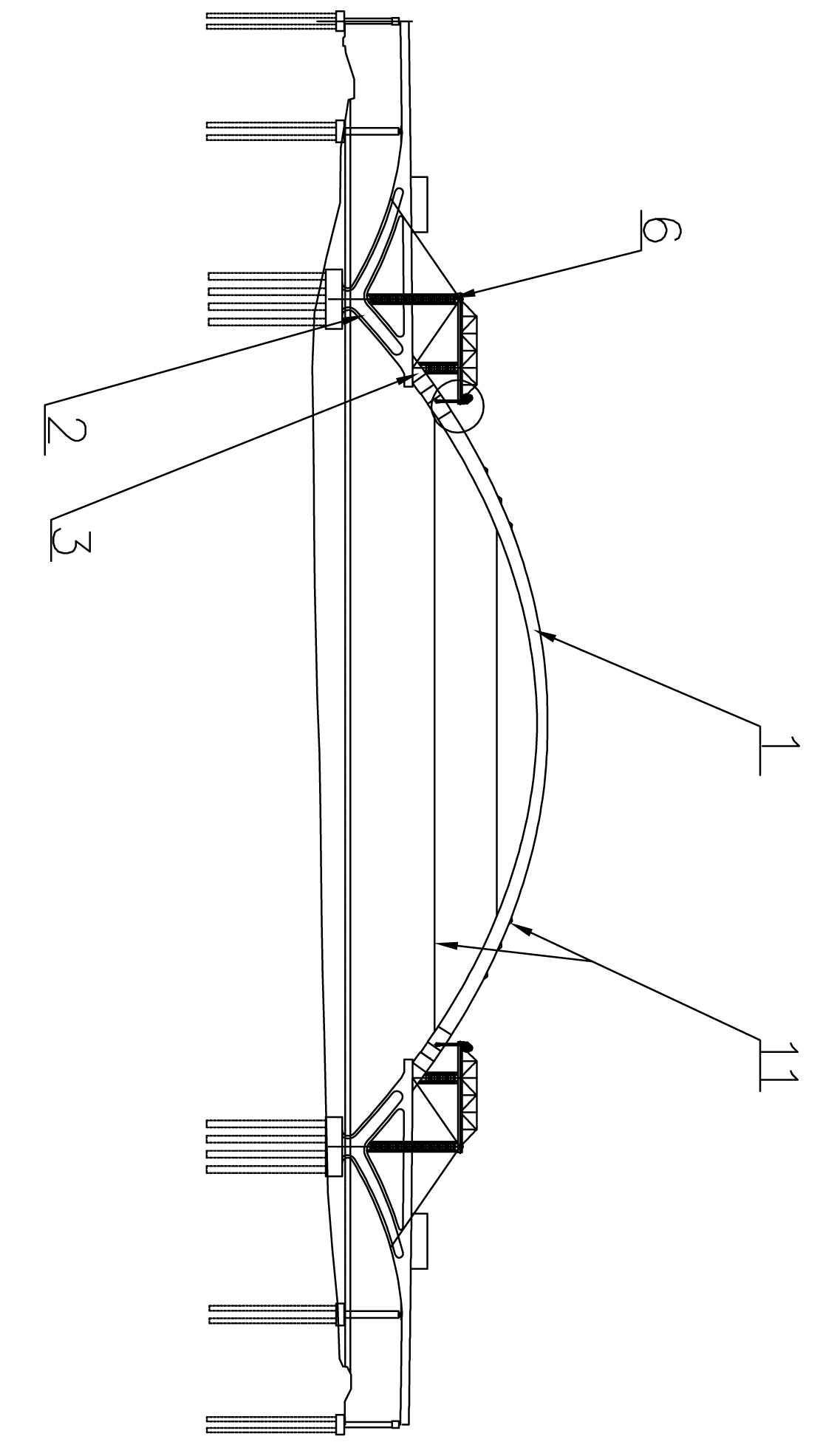

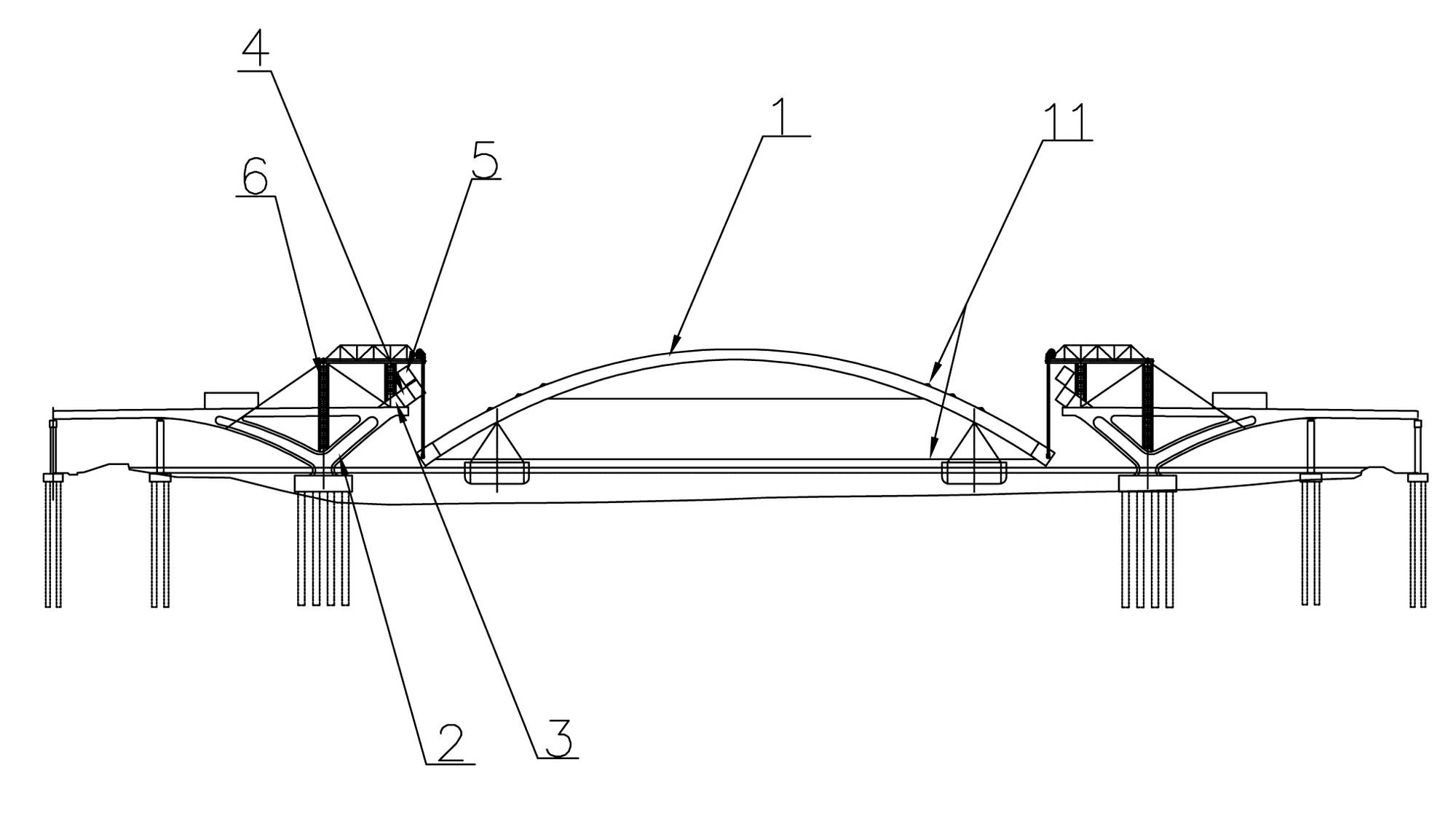

[0053] As a preferred embodiment of the present invention, step 2) includes the following steps:

[0054] , Pre-embed the embedded parts of the tower at the cap of the main pier 2, and pre-embed the shaped steel as the anchoring device for the tower, and pre-embed the shaped steel in the front and rear of the tower as the tower cable wind;

[0055] , Reserve a hole at the tower position of the main beam at the main pier 2;

[0056] , The front tower is directly welded on the embedded section of the arch rib.

[0057] As a preferred embodiment of the present invention, step 3) includes the following steps:

[0058] , Use the overturned formwork to construct the arch foot section, connect the main pier into a whole through temporary connection, and reserve holes as the positions of the tower columns during the bridge deck construction process;

[0059] 1. Use the floating crane to assemble the bracket and the arch foot segment, tighten the front and rear cable winds,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com