Intelligent lifting method and device for scraper knife in engineering machine

A technology of engineering machinery and shovel blades, which is applied in the field of intelligent lifting methods and devices for shovel blades in construction machinery, which can solve the problems of poor control of the lifting amount of shovel blades, high labor intensity of operators, and slow response, so as to improve operating efficiency , Simple and compact structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

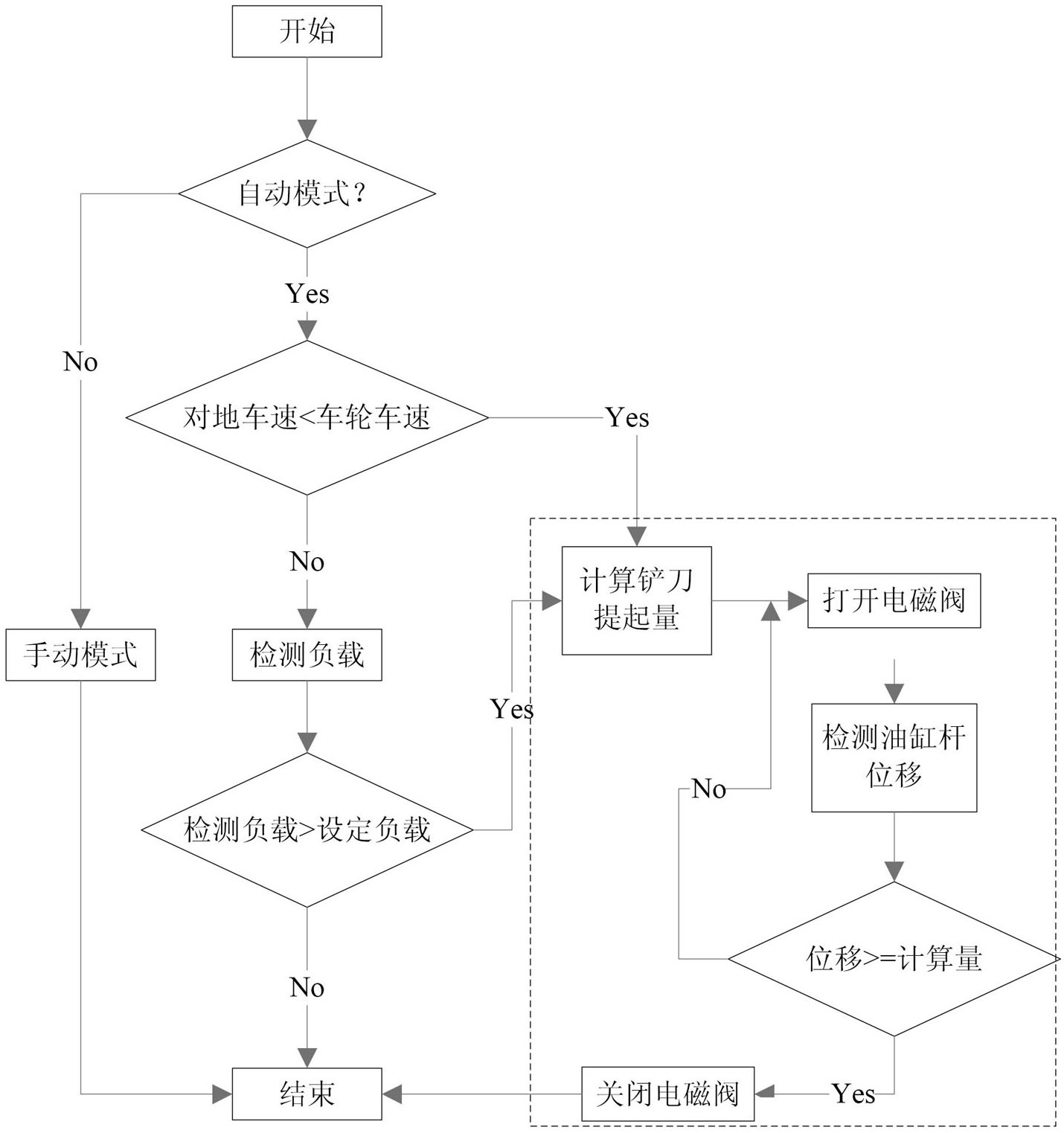

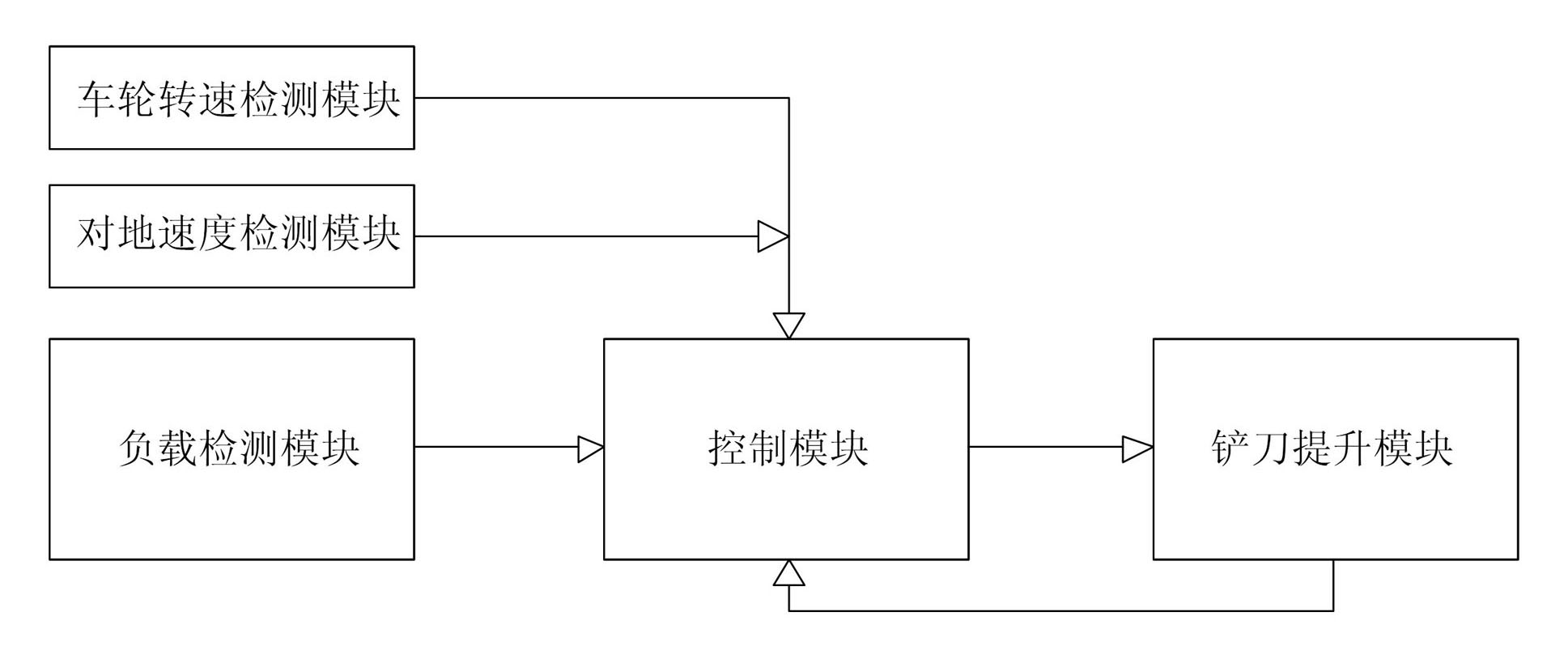

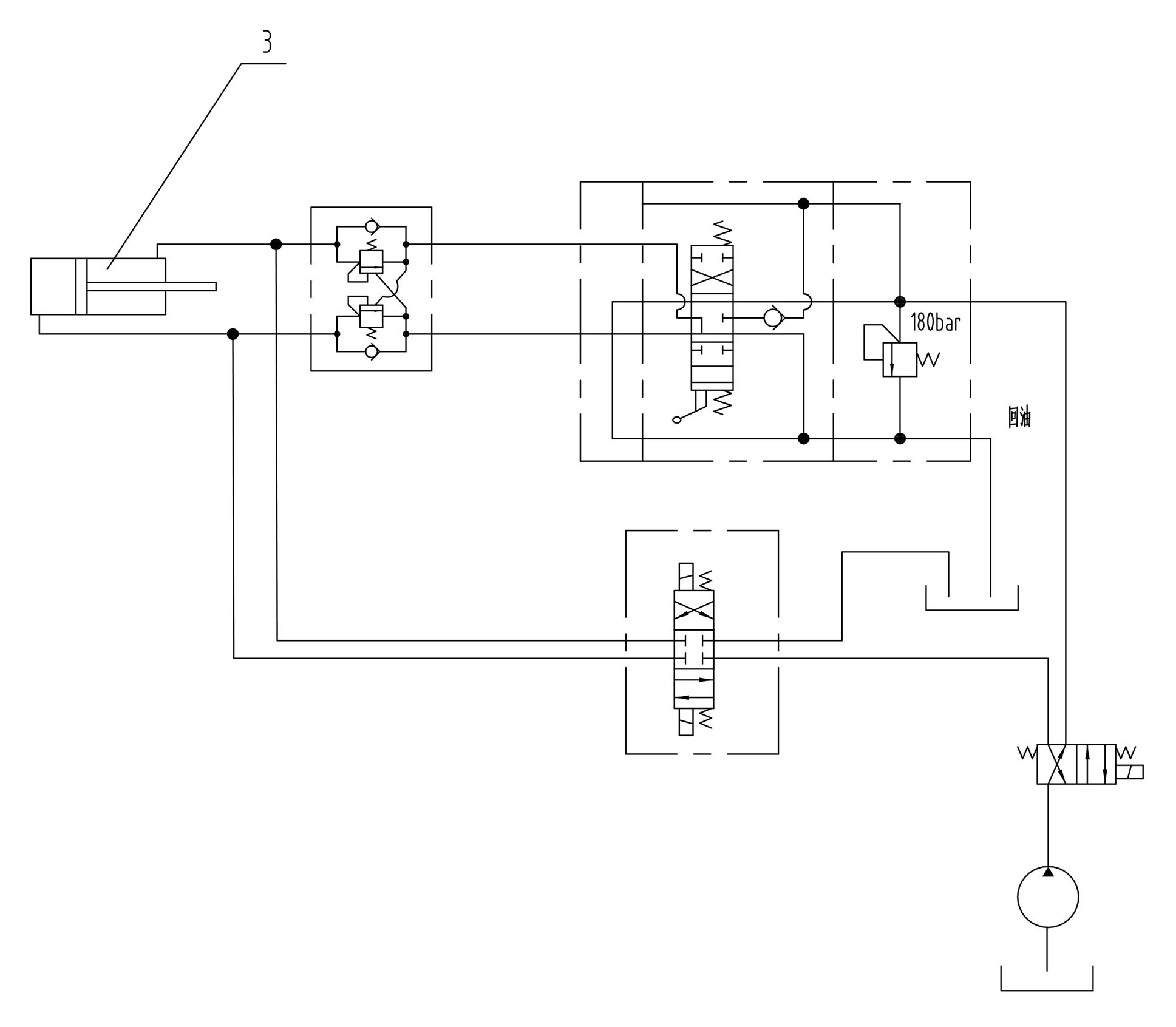

[0023] Such as figure 1 As shown, the present invention is used for the intelligent lifting method of the shovel in construction machinery, and its steps are:

[0024] ①Judge the current working mode: if it is manual mode, the work of the blade is completely completed by the operating handle; if it is automatic mode, turn to step ②;

[0025] ②Compare the converted vehicle speed of the current wheel speed with the current actual ground speed of the machine: if the current actual ground speed of the machine is less than the converted vehicle speed of the current wheel speed, it is determined that the wheels are slipping, and proceed to step ③; otherwise, proceed to step ④ ;

[0026] ③Output the command to lift the blade until the wheels slip or the blade is raised to the limit;

[0027] ④ Detection of blade load: When the power corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com