Fully mechanized mining gob-side entry retaining-based concrete block staggered joint longitudinal stacking wall forming method

A technology of leaving empty roadways and staggered joints, which is applied in the field of concrete block staggered joints and vertically coded into walls, which can solve the problems of height, strength, roadway surrounding rock stress and roof movement rules, and unfavorable stress conditions of walls in size, length and width , the poor stress state of the wall and other problems, to achieve the effect of simplifying the masonry process, reducing the amount of coal pillars left, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

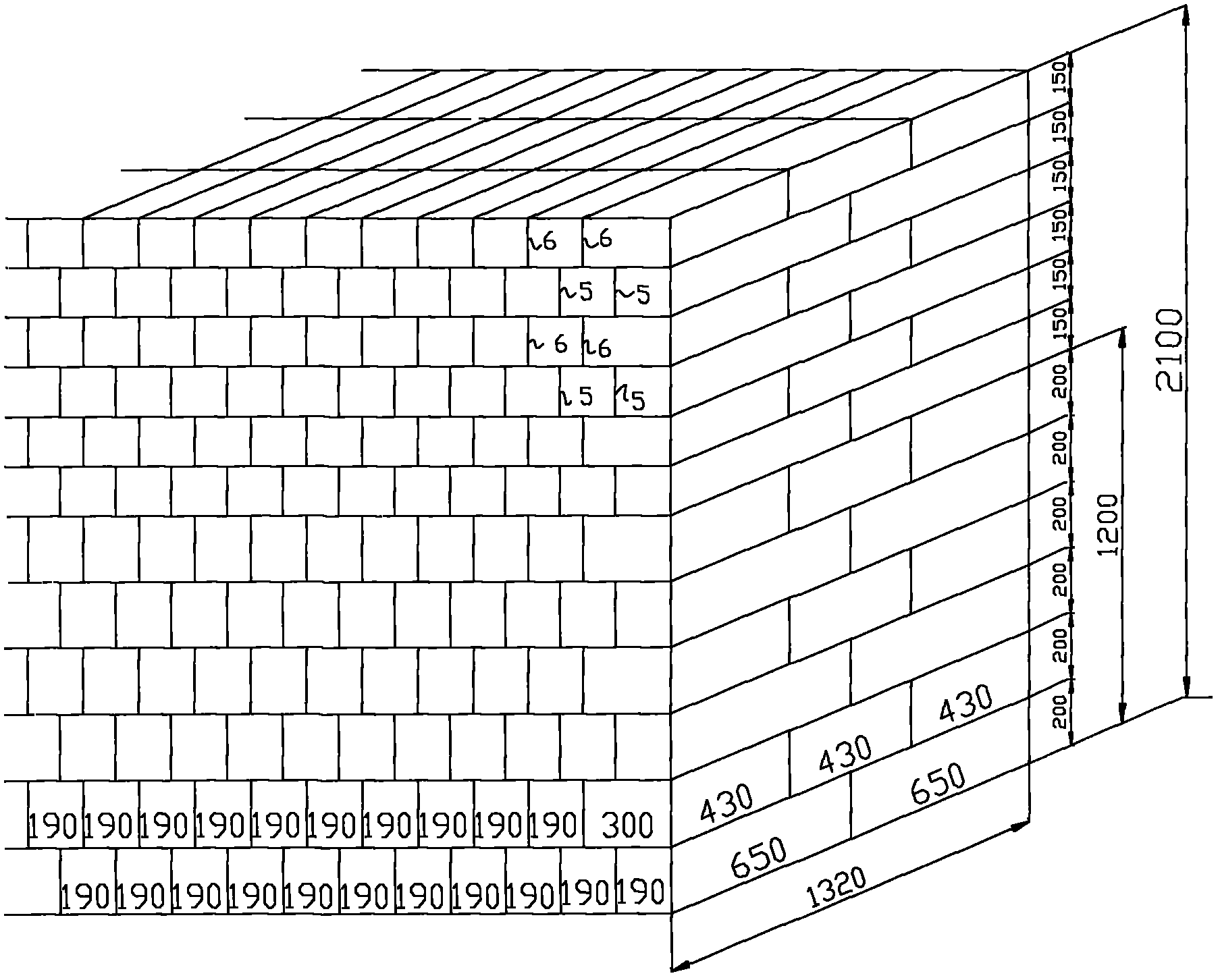

[0032] The present invention provides a method based on fully-mechanized mining gob-side entry retaining with concrete blocks staggered and vertically coded into walls. In order to make the purpose, technical solutions and advantages of the present invention clearer and clearer, the following will be combined with the accompanying drawings and embodiments to describe this The invention is further described in detail.

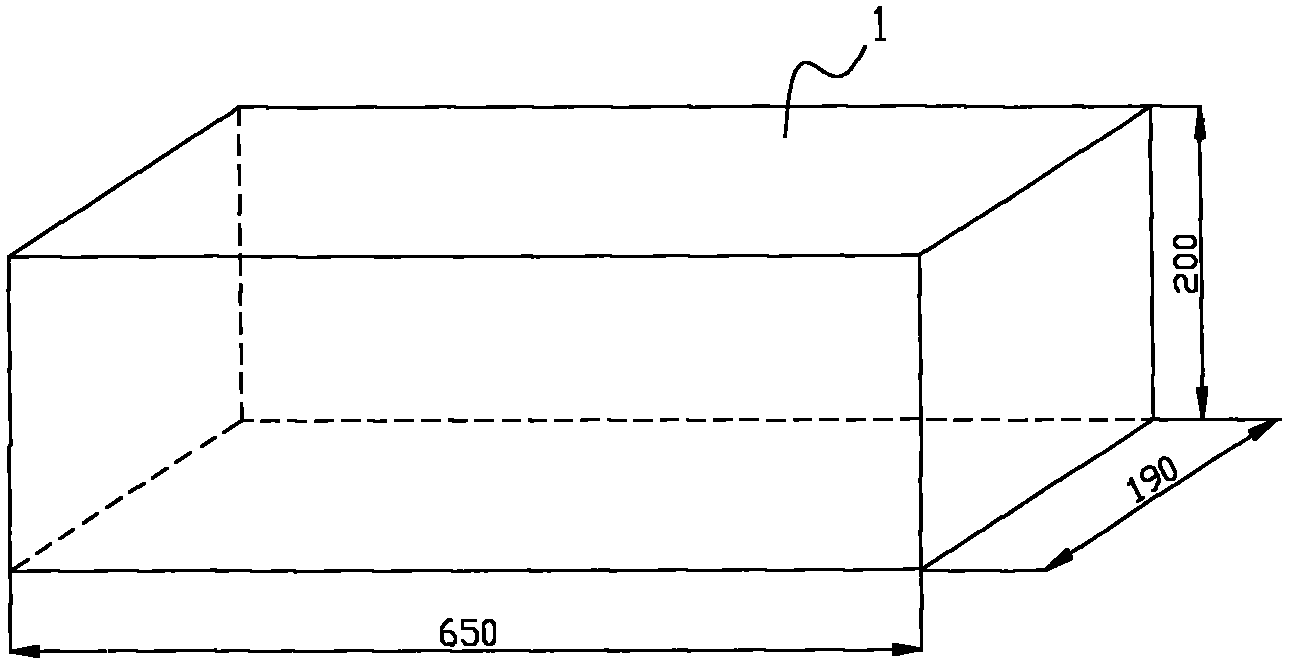

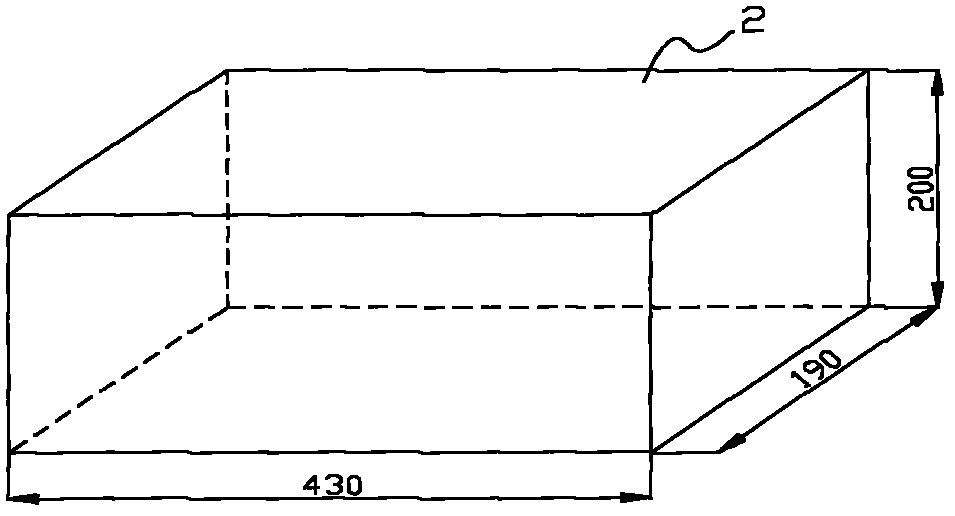

[0033] The invention provides a method based on fully mechanized mining gobside entry retaining with concrete blocks staggered and vertically coded to form a wall. Cement, sand, water, fly ash, and stones are prepared according to certain strength requirements and concrete is prepared by mechanical stirring, vibration ( concrete), the steel plate custom-made mold makes four kinds of concrete blocks of different weight types and sizes, and the concrete blocks are cured for a period of time after demoulding, so that the concrete blocks can reach 100% of the design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com