Nitrogen sealing gas shut-off valve

A gas cut-off valve and nitrogen sealing technology, which is applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of affecting the normal use of the valve, affecting the transmission of combustible gas, and the valve cannot be opened, so as to achieve uniform force and small installation space , the effect of small output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

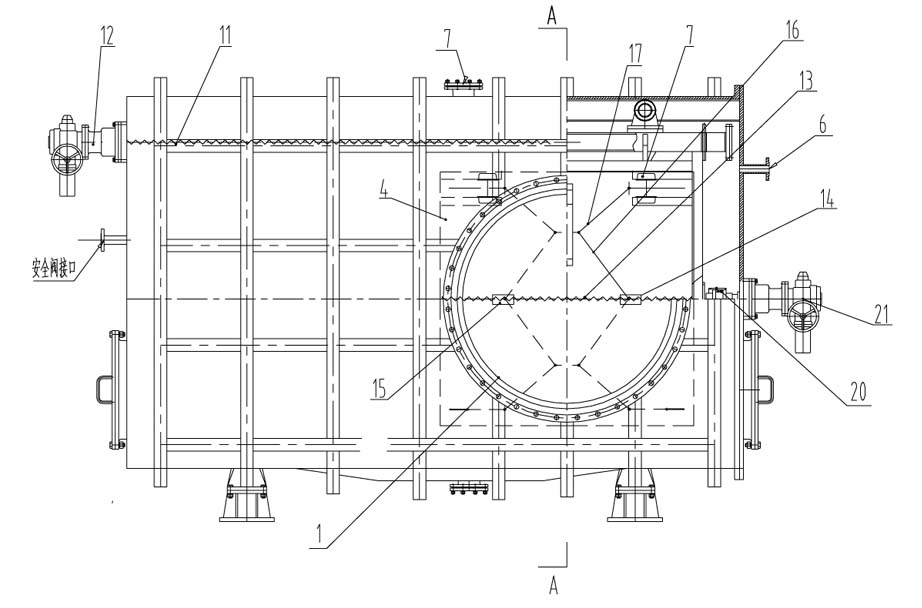

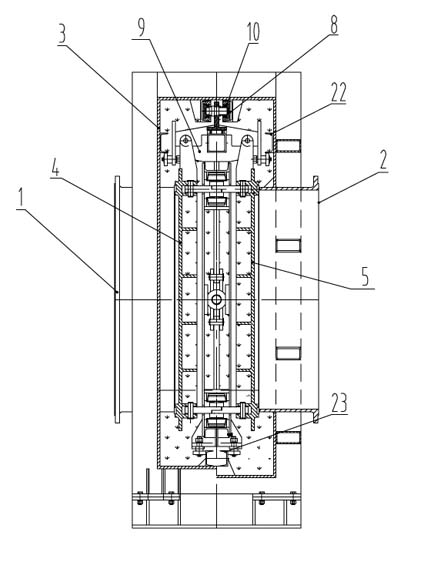

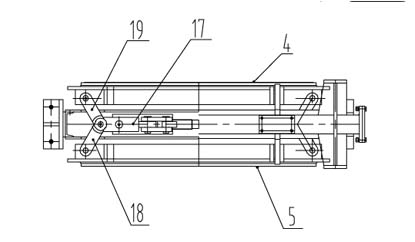

[0013] As shown in the figure, the nitrogen-sealed gas shut-off valve of the present invention includes a valve body 3 provided with an inlet 1 and an outlet 2, corresponding to the valve body 3 provided in the valve cavity of the valve body 3 with the inlet 1 and the outlet 2. The two valve plates 4, 5 are used to drive the opening and closing of the two valve plates 4, 5; the valve body wall is provided with a nitrogen inlet 6 and a gas discharge port 7 communicating with the valve cavity; On the top wall of the valve cavity, a track 8 is arranged horizontally perpendicular to the medium flow direction, and the two valve plates 4, 5 are connected with the hanging wheel 10 arranged in the track 8 through a connecting piece 9; There is a nut matched with the plate-moving screw 11, and the plate-moving screw 11 seals and extends out of the valve cavity to drive and connect with the plate-moving electric device 12; a connecting rod is arranged between the two valve plates 4 and 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com