Method for observing metallographic structure on titanium/steel explosion welding interface

A technology of explosive welding and metallographic structure, which is applied in the observation field of titanium/steel explosive welding interface metallographic structure, which can solve the problems of difficult to obtain a clear interface structure, non-corrosion resistance, etc., so that the interface metallographic structure is clearly visible , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

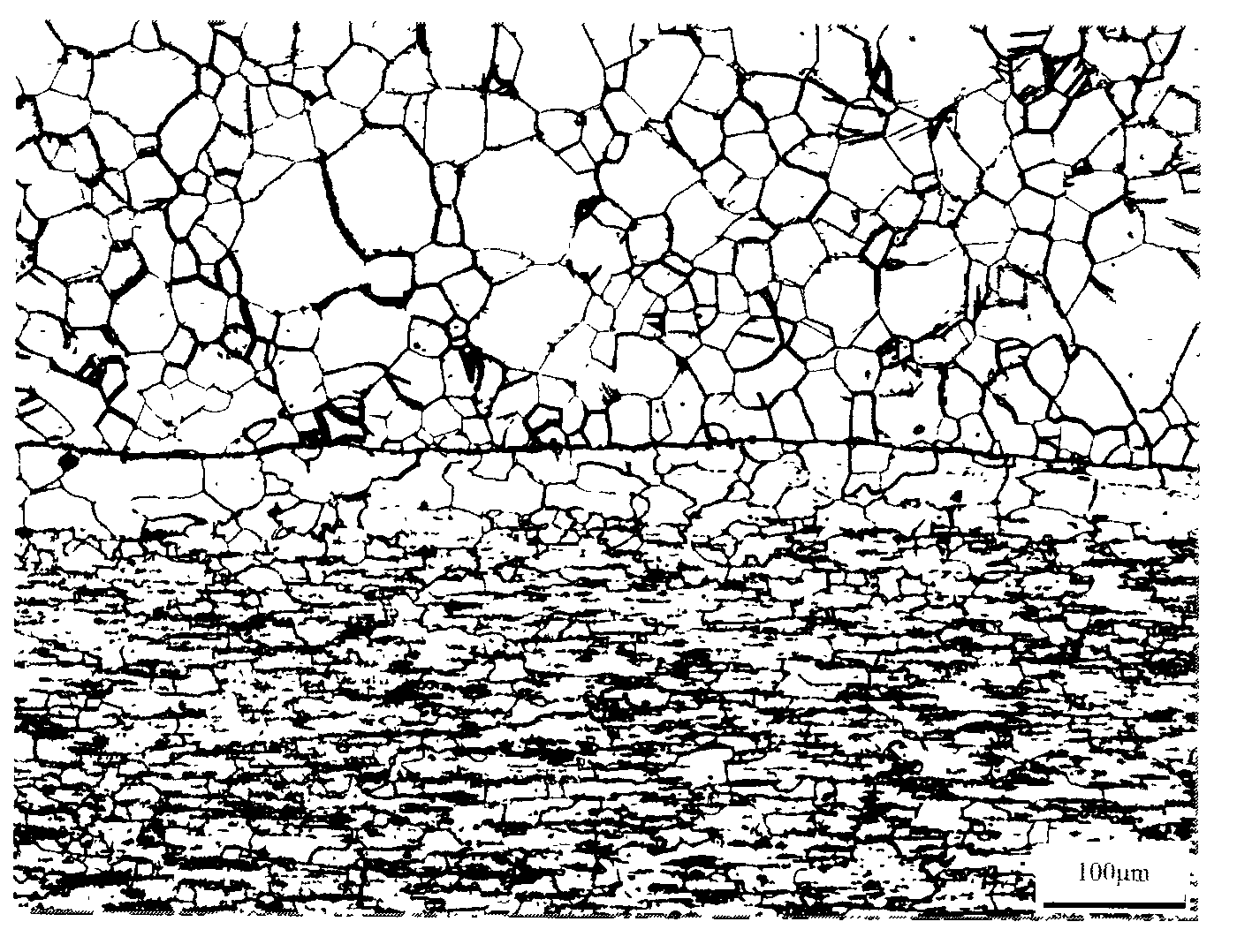

Embodiment 1

[0019] (1) Machining a metallographic observation plane at the titanium / steel explosive welding interface;

[0020] (2) Use the machined metallographic observation plane to 150 # , 700 # The metallographic water sandpaper is ground step by step, and the sand particles on the metallographic observation plane are washed away after grinding;

[0021] (3) The metallographic observation plane, which has been ground and washed away from sand, is pickled with HF solution with a volume percentage concentration of 10%;

[0022] (4) Put the metallographic observation plane after pickling on the polishing machine, using Cr 2 O 3 Solution and 2.5μm diamond powder for mechanical polishing;

[0023] (5) Use a corrosive solution to etch the part of titanium in the mechanically polished metallographic observation plane until the titanium surface becomes blue-gray, and then wipe the steel in the metallographic observation plane with a 2% volume percent nitric acid alcohol solution Part, make the steel...

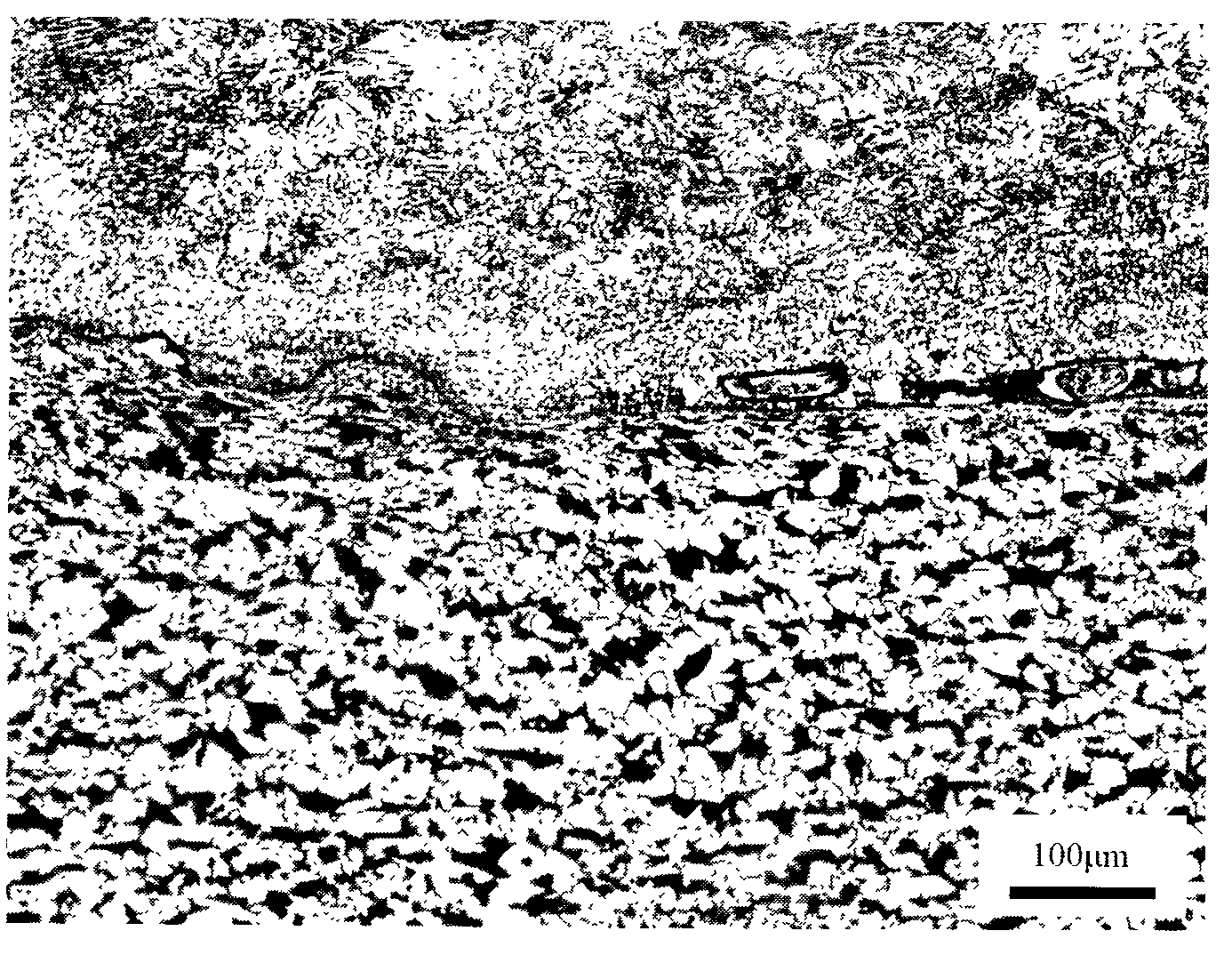

Embodiment 2

[0027] (1) Machining a metallographic observation plane at the titanium / steel explosive welding interface;

[0028] (2) Use the machined metallographic observation plane to 150 # , 700 # The metallographic water sandpaper is ground step by step, and the sand particles on the metallographic observation plane are washed away after grinding;

[0029] (3) The metallographic observation plane, which has been ground and washed away from sand, is pickled with HF solution with a volume percentage concentration of 15%;

[0030] (4) Put the metallographic observation plane after pickling on the polishing machine, using Cr 2 O 3 Solution and 2.5μm diamond powder for mechanical polishing;

[0031] (5) Use a corrosive solution to etch the part of the titanium in the mechanically polished metallographic observation plane until the titanium surface becomes blue-gray, and then wipe the steel in the metallographic observation plane with a 3% volume percent nitric acid alcohol solution Part, make the s...

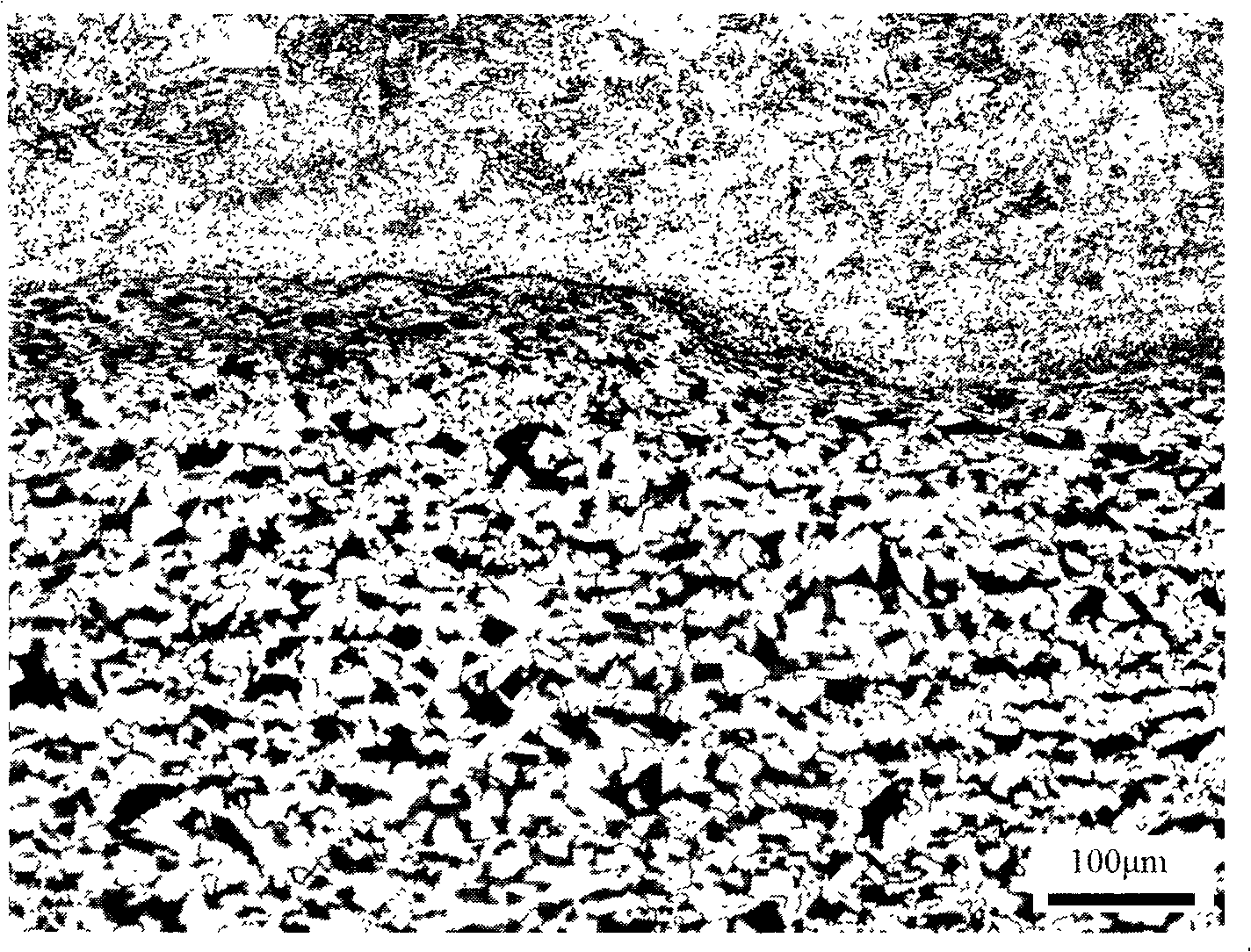

Embodiment 3

[0035] (1) Machining a metallographic observation plane at the titanium / steel explosive welding interface;

[0036] (2) Use the machined metallographic observation plane to 150 # , 700 # The metallographic water sandpaper is ground step by step, and the sand particles on the metallographic observation plane are washed away after grinding;

[0037] (3) The metallographic observation plane, which has been ground and washed away from sand, is pickled with HF solution with a volume percentage concentration of 20%;

[0038] (4) Put the metallographic observation plane after pickling on the polishing machine, using Cr 2 O 3 Solution and 2.5μm diamond powder for mechanical polishing;

[0039] (5) Use a corrosive solution to etch the part of titanium in the mechanically polished metallographic observation plane until the titanium surface becomes blue-gray, and then wipe the steel in the metallographic observation plane with a 4% volume percent nitric acid alcohol solution Part, make the steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com