Device for keeping negative pressure in chimney after assembling fume desulfating device

A technology of desulfurization device and holding device, which is applied in the direction of exhaust gas exhaust device, combustion product treatment, combustion method, etc., can solve problems such as chimney corrosion, achieve the effects of avoiding the influence of corrosion, ensuring normal operation, and easy operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

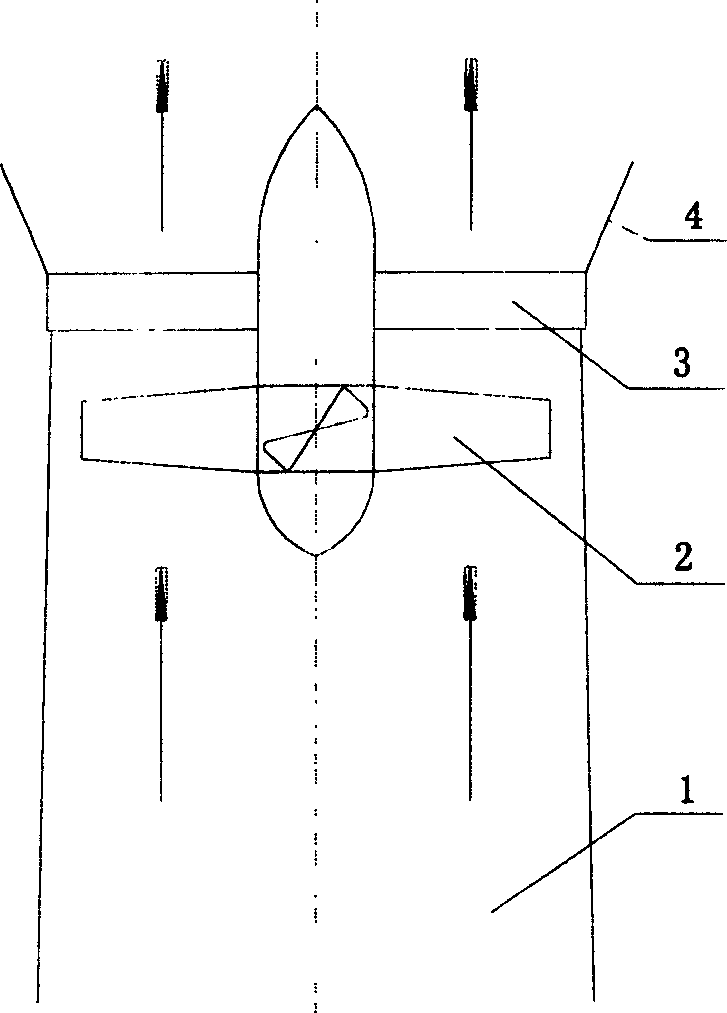

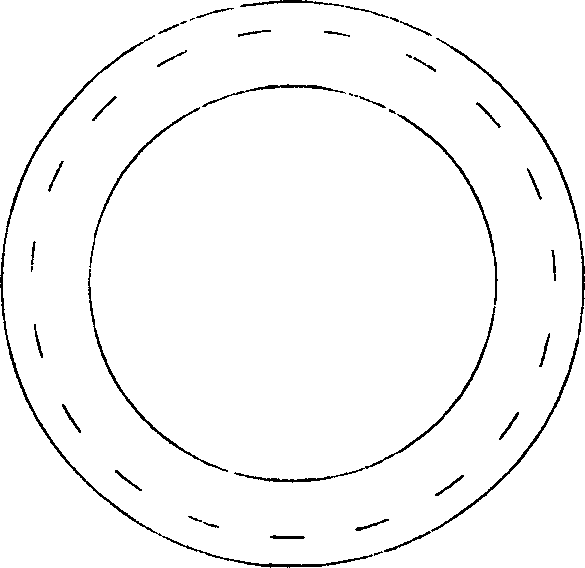

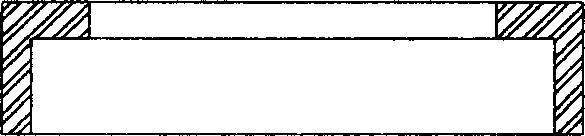

[0012] The device is composed of an axial flow fan 2, a vibration damping base 3, and a diffuser tube 4, wherein the vibration damping base 3 is a hollow ring, and the axial flow fan 2 is fixed on the vibration damping base 3 and is located on the vibration damping base 3. The middle of the diffuser tube 4 is a trumpet-shaped hollow ring with a large upper part and a smaller lower part.

[0013] 1. Before adopting the device of the present invention, the current situation of the chimney will be evaluated, including the structure and material of the chimney, corrosion or damage, design life and service life, operating conditions, etc. After evaluating and analyzing the possible load and vibration conditions of the chimney, the design and installation of the device of the present invention are started.

[0014] 2. Design of the device. When designing the device, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com