Rotary base plate tracking sun automatically

A slewing chassis, automatic tracking technology, applied in non-electric variable control, generator/motor, photovoltaic module support structure, etc., can solve problems such as bearing capacity, stability, wind load resistance and snow load resistance are not satisfactory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

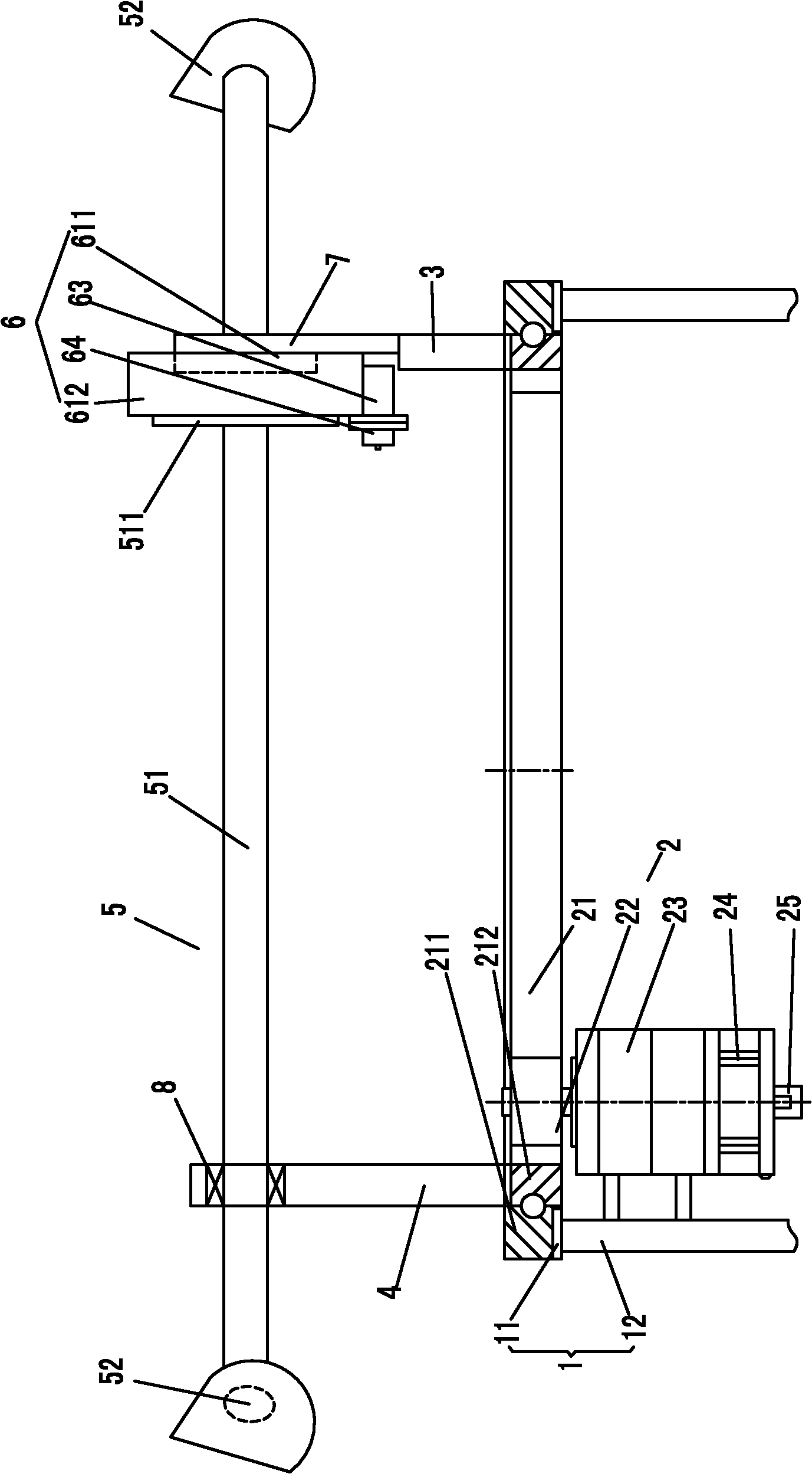

[0019] See figure 1 As shown, the slewing chassis for automatically tracking the sun of the present invention includes a base 1, a horizontal slewing mechanism 2, a main column 3, an auxiliary column 4, a light support base 5, a pitch slewing mechanism 6 and a vertical fixing plate 7;

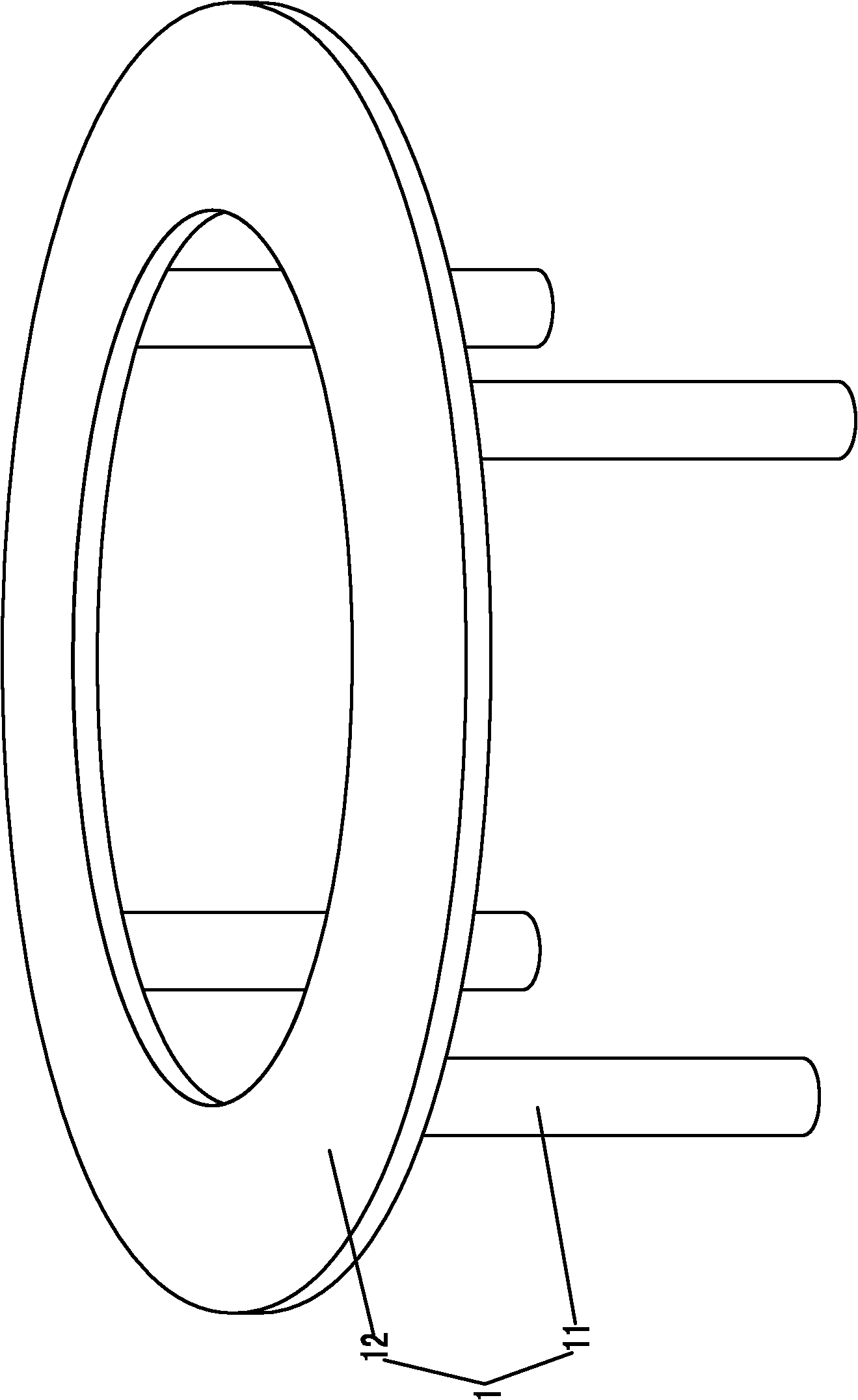

[0020] Such as figure 2 As shown, the base 1 is formed by connecting a flange base 11 and four legs 12 under the flange base 11;

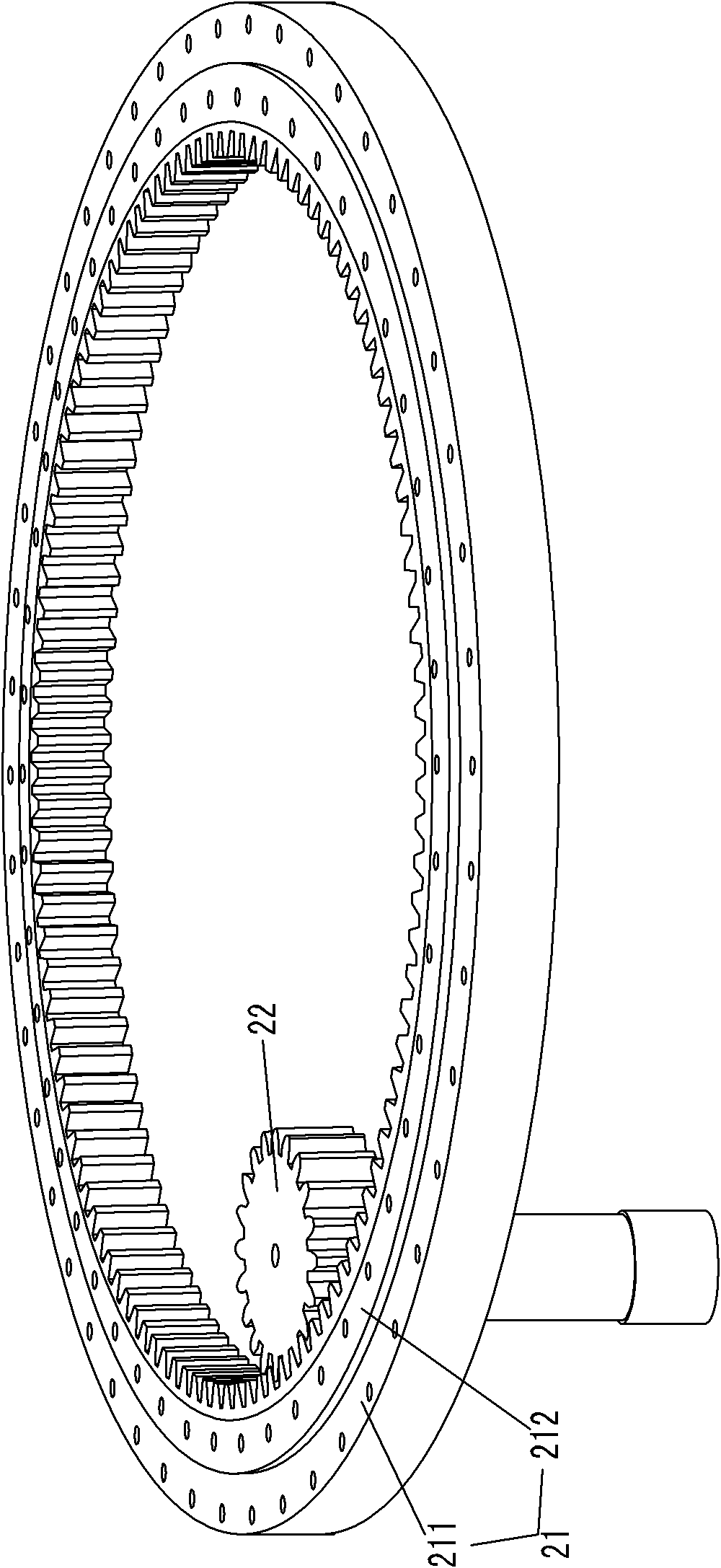

[0021] Please combine figure 1 with image 3 As shown, the horizontal slewing mechanism 2 includes a horizontal slewing support 21, a drive gear 22, a first reducer 23, a first DC motor 24, and a first automatic controller 25. The horizontal slewing support 21 is an inner ring with a diameter of 1-3 meters. Toothed slewing support, the fixed gear ring 211 of the horizontal slewing support 21 is installed on the flange seat 11, and the drive gear 22 is fixed on the output shaft of the upper part of the first reducer 23 and meshes with the movable gear ring 212 of the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com