Rapid lifting device of angle steel straightening roll

A hoisting device and straightening roller technology, applied in the field of mechanical processing, can solve the problems of inability to achieve rapid hoisting, difficulty in hoisting, etc., and achieve the effects of beautiful and compact appearance, fast replacement, and good balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

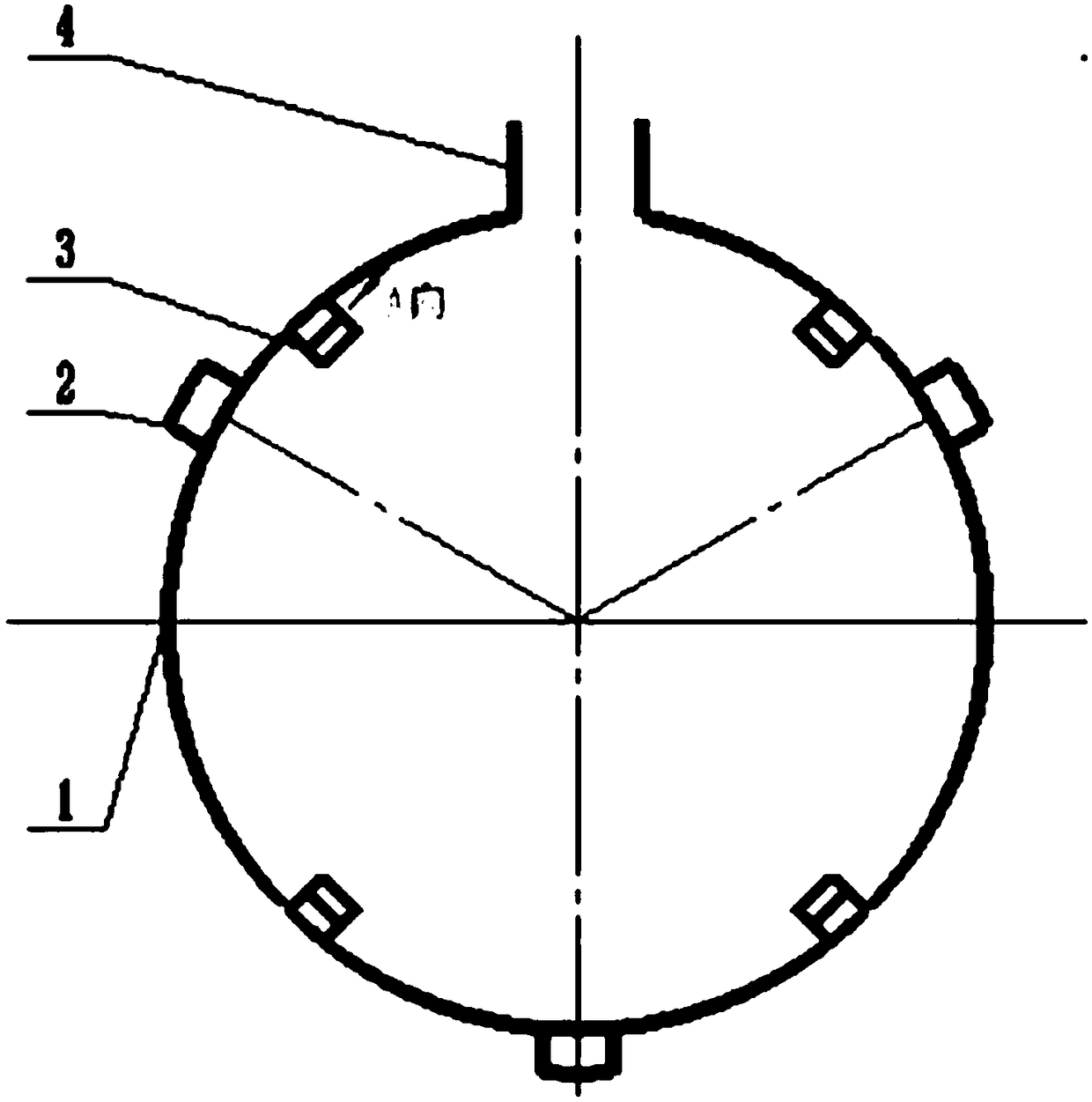

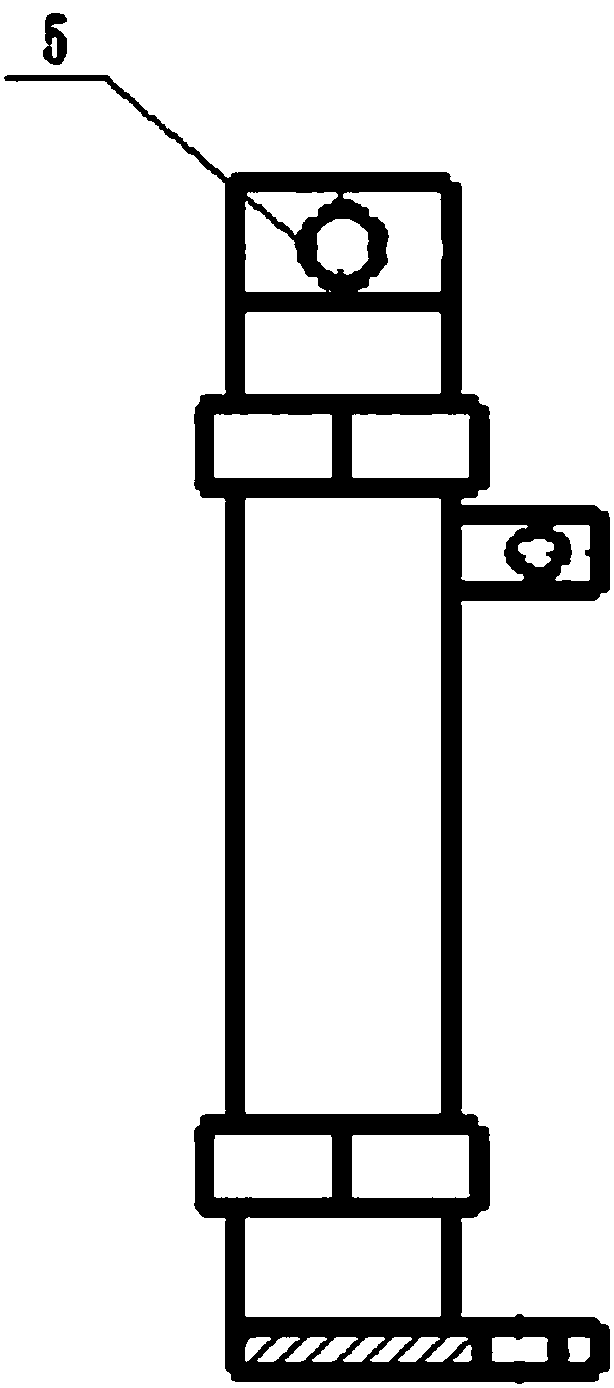

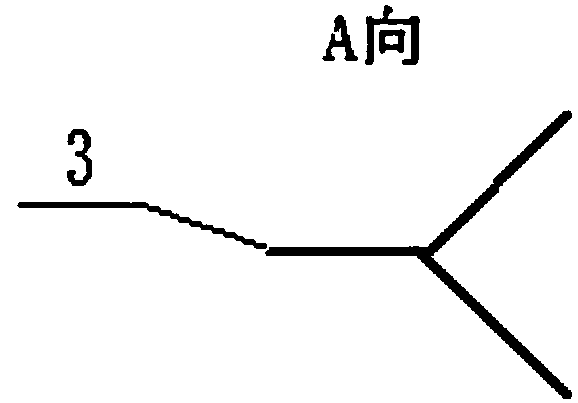

[0020] The open circular outer ring covers the angle steel straightening roller for hoisting, and three lifting lugs and four V-shaped baffles are respectively fixed on the outer wall and the inner wall of the circular outer ring. The opening of the circular outer ring is provided with two vertical plates parallel to each other, and the two vertical plates extend outward from the opening of the circular outer ring. A pin hole A is provided at the center of the two vertical plates, and the pin A is inserted into the pin hole A. The connecting lines between two adjacent lifting lugs and the center of the circular outer ring respectively are 120 degrees, and the lifting lugs are connected with the hook of the crown block through the lifting belt. Four V-shaped baffles are symmetrically distributed on the inner wall of the circular outer ring. Pin A is provided with seven pin holes, and pin B is inserted into the pin holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com