Method for improving severe saline-alkali soil by using open trench and hidden filler layer

A technology of heavy saline-alkali land and filling layer, which is applied in the direction of soil preparation, application, agriculture, etc. It can solve the problems of difficult to completely improve saline-alkali land, large amount of fresh water, land reverse seepage, etc., and achieve slope protection to prevent soil loss during cultivation, improve soil quality, and prevent evaporation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

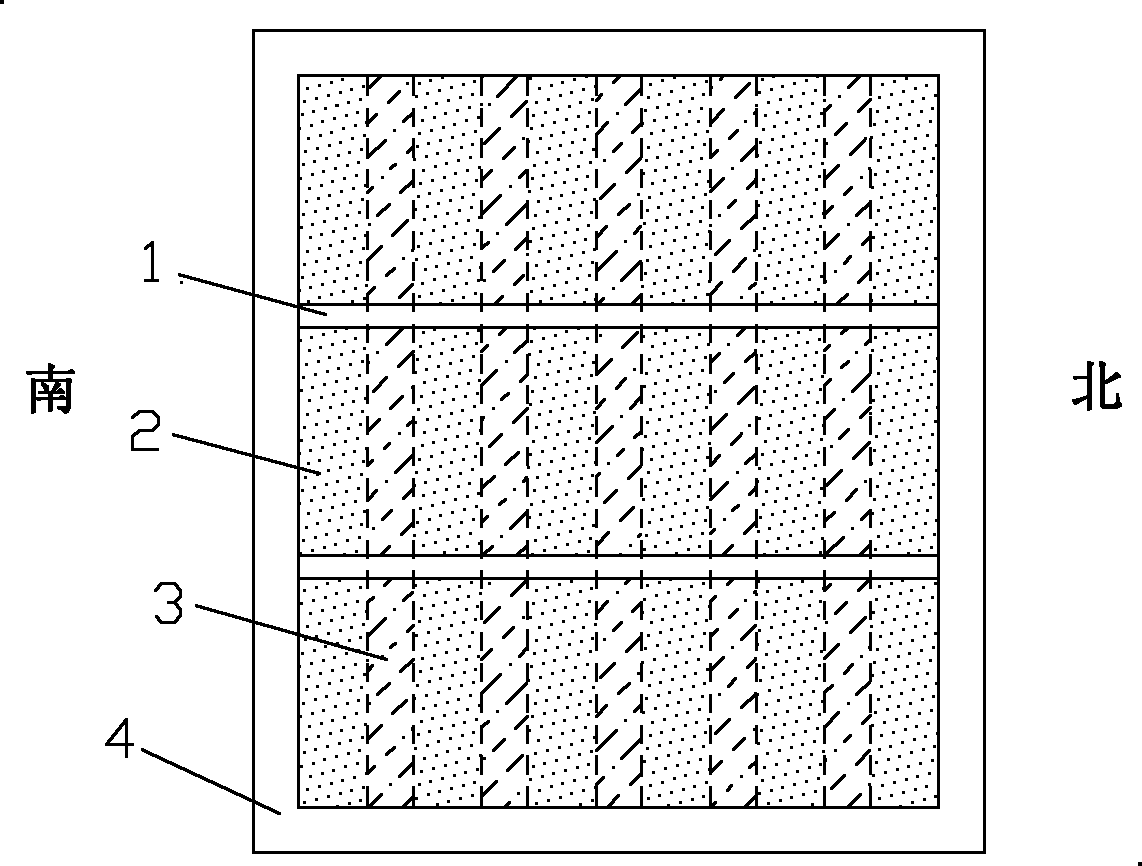

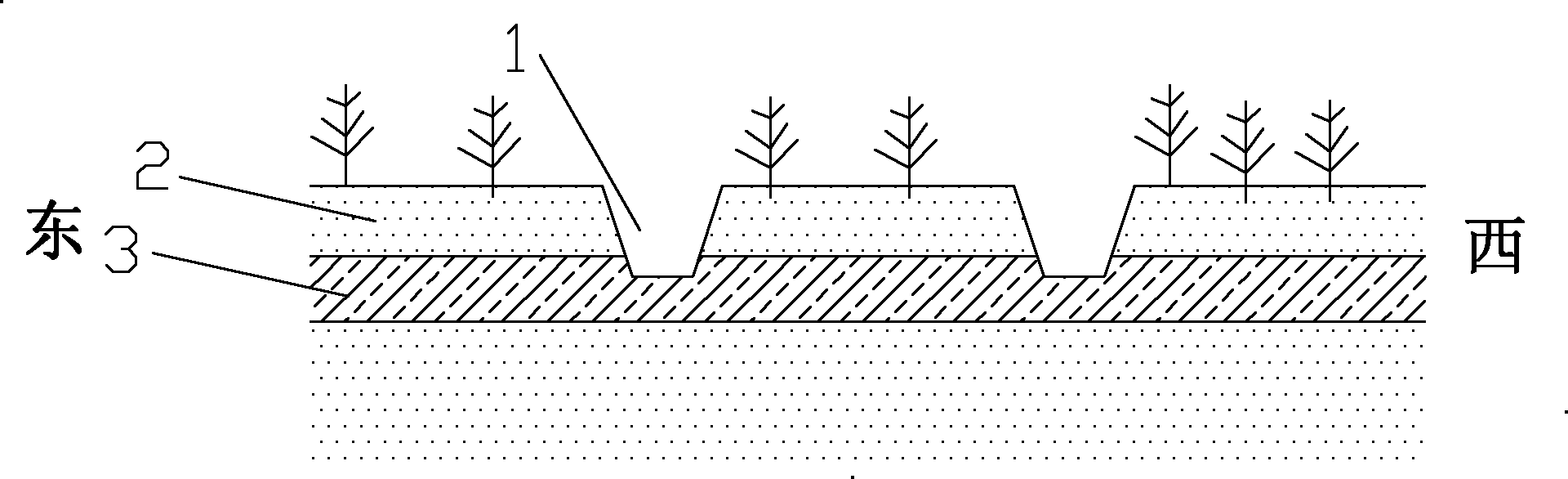

[0024] The method for improving severe saline-alkali land with open ditch and dark filler layer described in this example is applicable to the improvement of severe saline-alkali land with groundwater depth greater than 1.1m and area of saline-alkali land less than or equal to 5 mu. figure 1 , figure 2 and Figure 5 As shown, the specific method is:

[0025] (1) In the saline-alkali land, several deep ditches with a width of 1.0m and a depth of 1.1m are dug out by mechanical equipment along the east-west direction, and the distance between each deep ditch is 6m. 20% of. Place the 30cm-thick mellow soil excavated below the ground in a concentrated manner, and place the 80cm-thick raw soil downwards in a concentrated manner.

[0026] (2) Dig out the main row of saline-alkali ditches 1 along the north-south direction with the upper and lower widths of 1.4m-1.6m and 0.5m-0.6m and a depth of 70cm, and the distance between each main row of saline-alkali ditches 1 is 15m-20m ,...

Embodiment 2

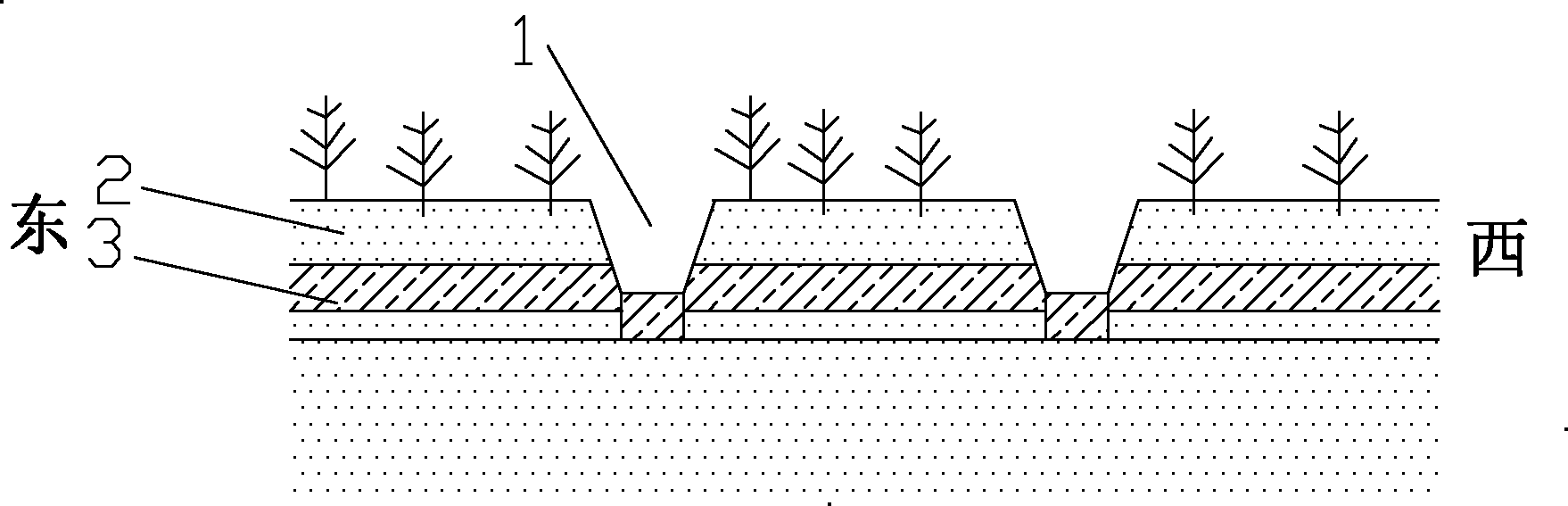

[0034] The method for the improvement of severe saline-alkali land by the dark filling layer of the open ditch described in this embodiment is applicable to the reconstruction of severe saline-alkali land with a groundwater depth greater than 1.1m and an area of saline-alkali land greater than 5 mu and less than or equal to 20 mu, such asfigure 1 , image 3 and Figure 5 As shown, the specific method is:

[0035] (1) In the saline-alkali land, a number of deep ditches with a width of 1.0m and a depth of 1.1m are dug along the east-west direction, and the distance between the ditches is 6m. The area of all the ditches accounts for 25% of the total area of the saline-alkali land. . Place the 30cm-thick mellow soil excavated below the ground in a concentrated manner, and place the 80cm-thick raw soil downwards in a concentrated manner.

[0036] (2) Excavate the main row of saline-alkali ditches 1 along the north-south direction with the upper and lower widths of 1.4m-1.6m...

Embodiment 3

[0044] The method for improving severe saline-alkali land with open ditch and dark filler layer described in this example is applicable to the improvement of severe saline-alkali land with groundwater buried depth greater than 1.1m and area of saline-alkali land greater than 20 mu, such as figure 1 , Figure 4 and Figure 5 As shown, the specific method is:

[0045] (1) In the saline-alkali land, several deep ditches with a width of 1.0m and a depth of 1.1m are dug along the east-west direction, and the distance between the ditches is 6m. The area of all the ditches accounts for 30% of the total area of the saline-alkali land. . Place the mellow soil excavated 30cm below the ground in a concentrated manner, and then place the raw soil 80cm down.

[0046] (2) Along the north-south direction, excavate the main row of saline-alkali ditches 1 with the upper and lower widths of 1.4m-1.6m and 0.5m-0.6m and a depth of 75cm. The distance between each main row of saline-alkali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com