Vacuum suction device for frame and operation method thereof

A plate frame and vacuum technology, which is applied in the field of vacuum clamping devices for plate frames, can solve the problems of uneven pressure, reduced work efficiency, uneven pressure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

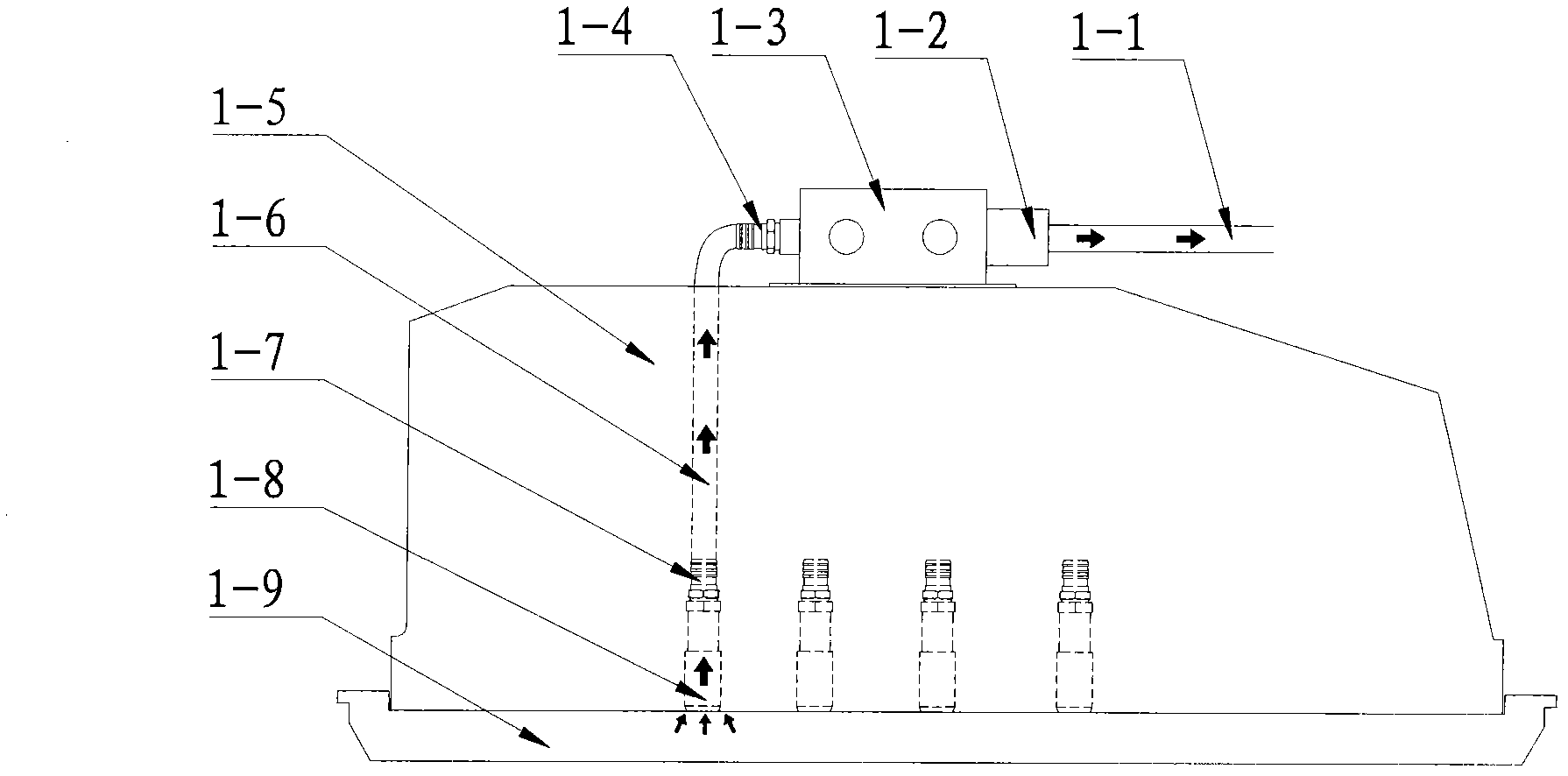

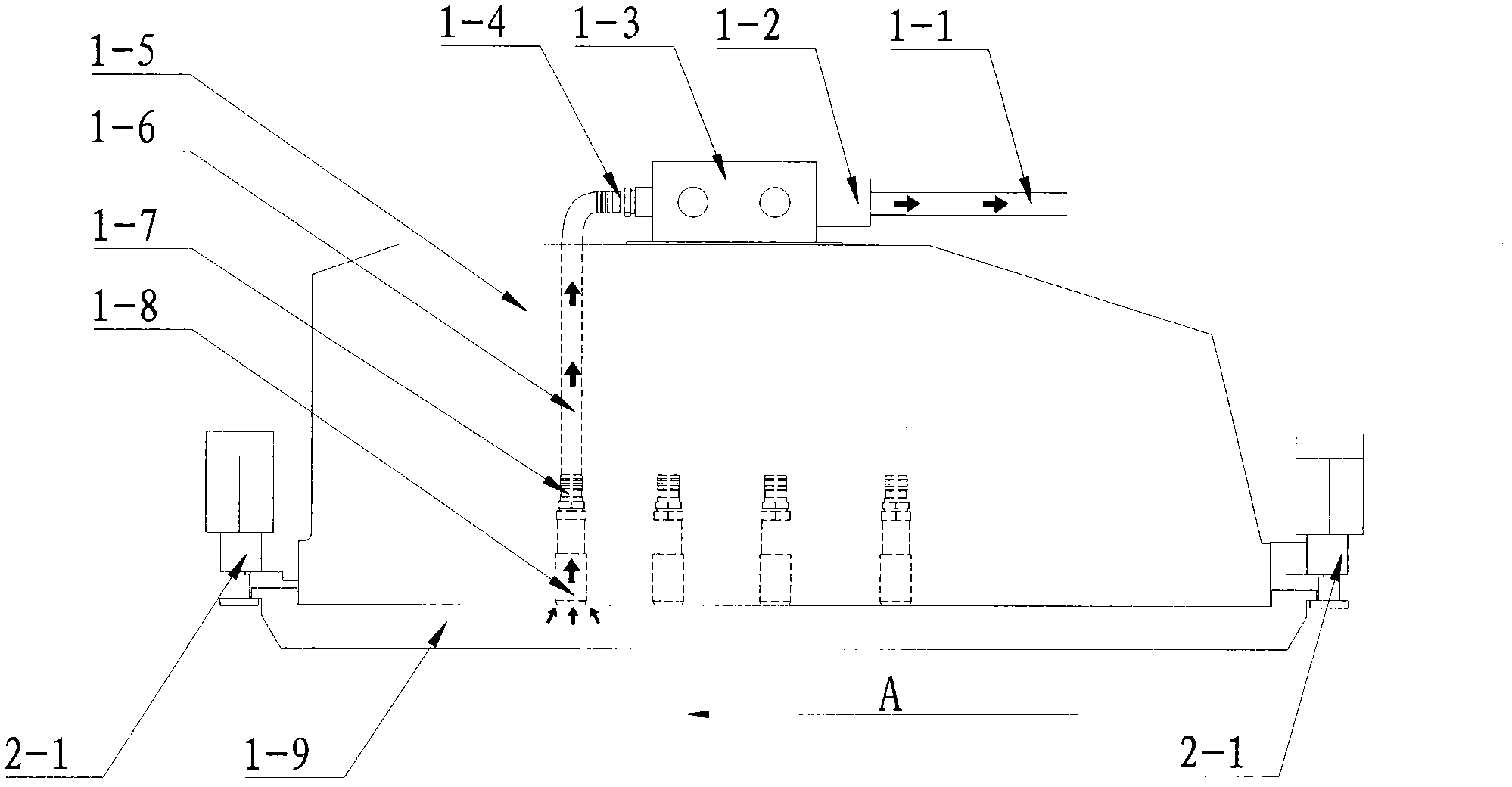

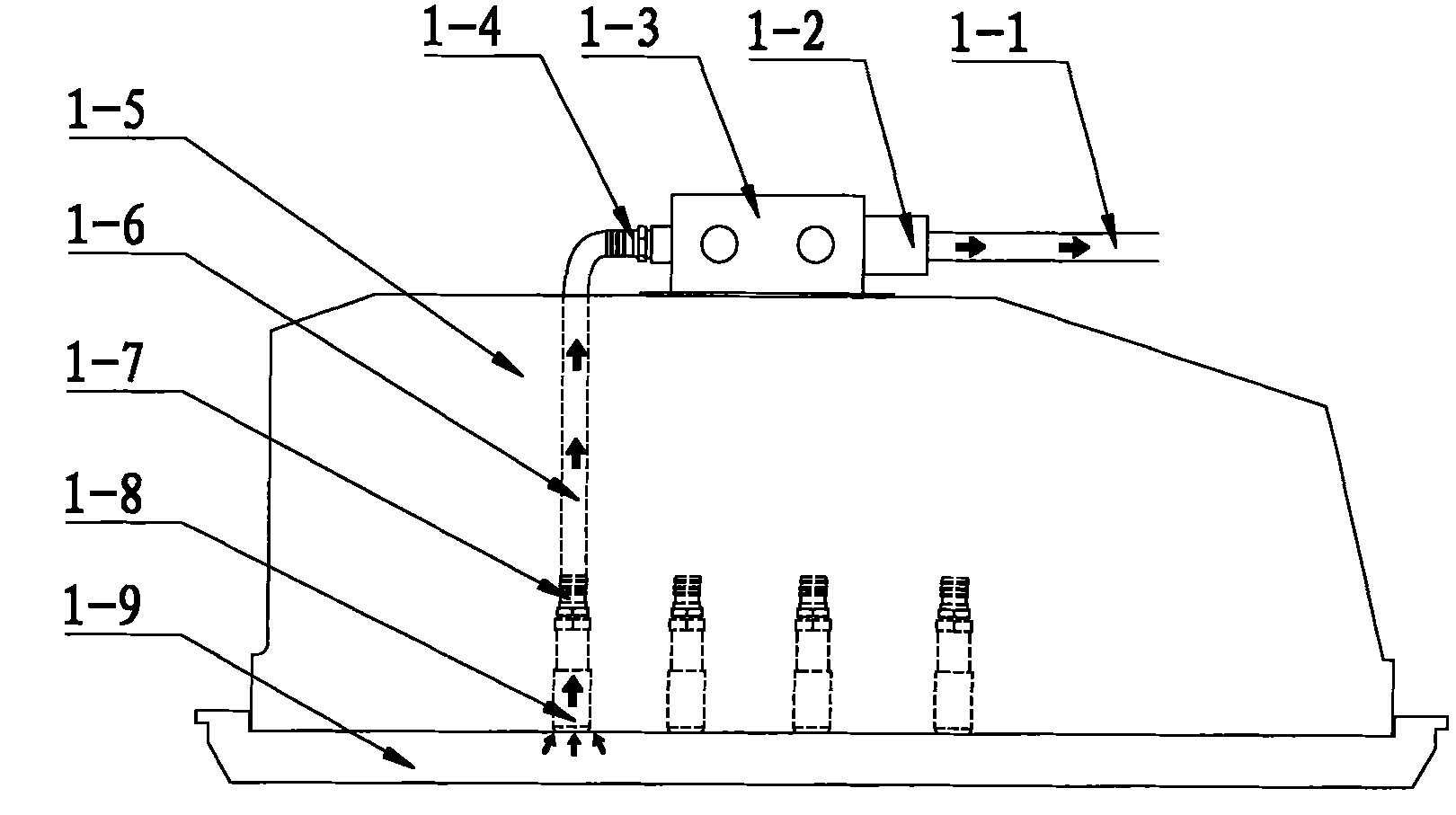

[0023] Example: A vacuum suction device for the plate frame (see figure 1 , figure 2 ), which is characterized in that it includes the main airway suction pipe 1-1, the platform 1-5, the branch airway pipe 1-6, the branch airway pipe joint 1-7, the suction nozzle 1-8 and the frame 1- 9; The suction nozzle 1-8 is fixedly installed in the platform 1-5 according to the thread and is perpendicular to the frame 1-9, and the end surface of the suction nozzle 1-8 is on the same plane as the lower plane of the platform 1-5 Plane, the other end of the suction nozzle 1-8 is connected with the branch pipe joint 1-7 according to the thread; one end of the branch suction pipe 1-6 is connected with the branch pipe joint 1-7, and the other One end is connected with one end of the main air suction pipe 1-1; the other end of the main air suction pipe 1-1 is connected with the vacuum generator; the middle area of the frame 1-9 has a certain deformation and Collapse.

[0024] A gas path instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com