Automatic winter melon paste stuffing weighing and conveying device

A technology of automatic measurement and transmission equipment, applied in the direction of automatic packaging control, liquid materials, packaging, etc., can solve the problems of poor measurement and weighing accuracy, low work efficiency, and high labor intensity of workers, and achieve stable and reliable operation, simple structure, Design novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

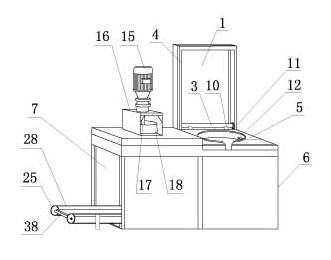

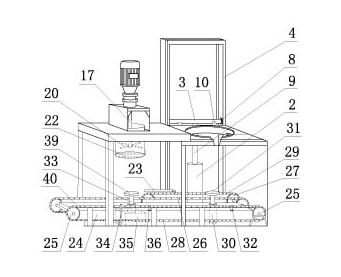

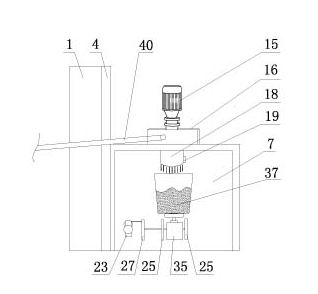

[0018] The automatic metering and conveying equipment for winter melon puree stuffing consists of an electric control cabinet 1, a jacking cylinder 2, a jacking roller 3, a guide rail 4, a chuck 5, a housing 6, a conveying metering device and a filling device. The bottom of the housing 6 is provided with a conveying metering device, and the left side of the housing 6 is provided with a conveying port 7, and one end of the conveying metering device extends to the outside of the housing through the conveying port 7, the purpose of which is to facilitate connection with other conveying lines. A filling device is installed on the top of the left side of the casing 6, a chuck 5 is installed on the top of the right side of the casing 6, and an electric control cabinet 1 is installed on the back of the right side of the casing 6. Between the electric control cabinet 1 and the casing 6 A guide rail 4 is provided, and a jacking roller 3 is installed on the guide rail 4 through a pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com