Manufacturing method of surface mounted device resistor

A manufacturing method and chip resistor technology, which is applied in the direction of resistor manufacturing, resistors, and resistors with lead-out terminals, can solve the problems of weakened market competitiveness, high production costs, and high prices, so as to enhance market competitiveness and ensure uniformity. The effect of excellent uniformity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] Embodiment: A kind of manufacturing method of chip resistor, is based on using direction, and its manufacturing steps are as follows:

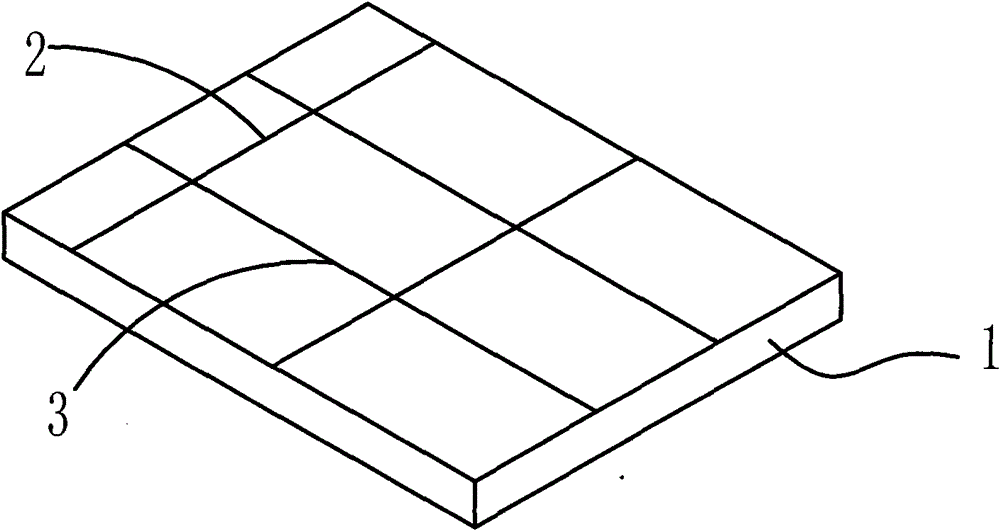

[0053] a. prepare an insulating substrate 1, and form a plurality of horizontal folding lines 2 and a plurality of longitudinal folding lines 3 on the upper surface 11 and the lower surface 12 of the insulating substrate evenly corresponding to the grid;

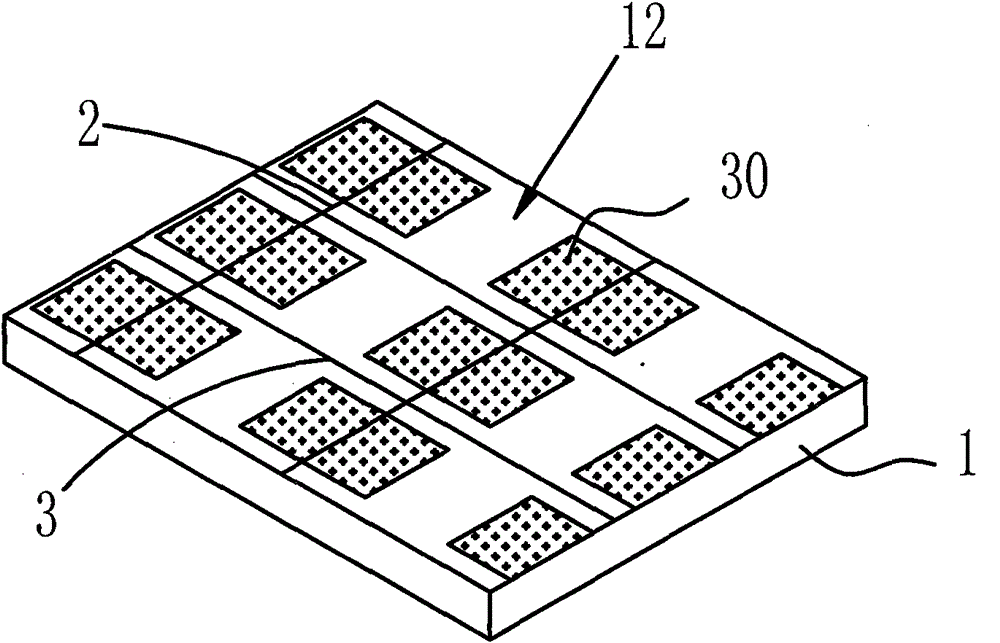

[0054] b. Print the silver paste on the lower surface 12 of the insulating substrate 1 at set intervals by screen printing, dry and sinter to form each back electrode 30, and the position of each back electrode 30 is to correspond to the horizontal fold The line 2 is the transverse center line and each back electrode 30 is located in the middle of two adjacent longitudinal folding lines 3;

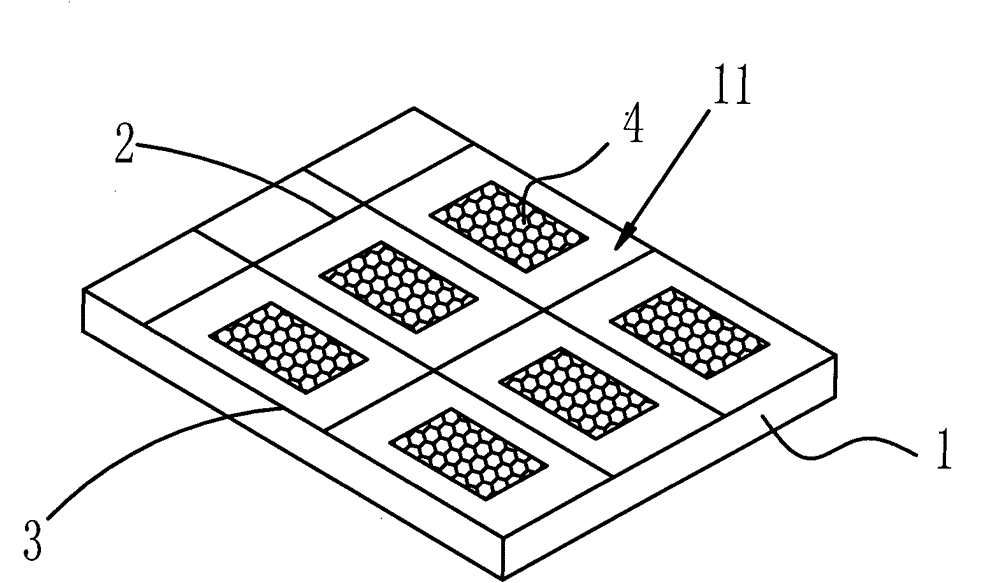

[0055] c. Print the resistance paste on the upper surface 11 of the insulating substrate 1 by screen printing, dry and sinter to form each resistance layer 4, and the position of each resistance l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com