A wind turbine blade

A technology of wind turbines and blades, applied to wind engines, wind engines consistent with the wind direction, engines, etc., can solve the problems of low manufacturing stability, high part cost, and unallowable manufacturing locations, etc., and achieve the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

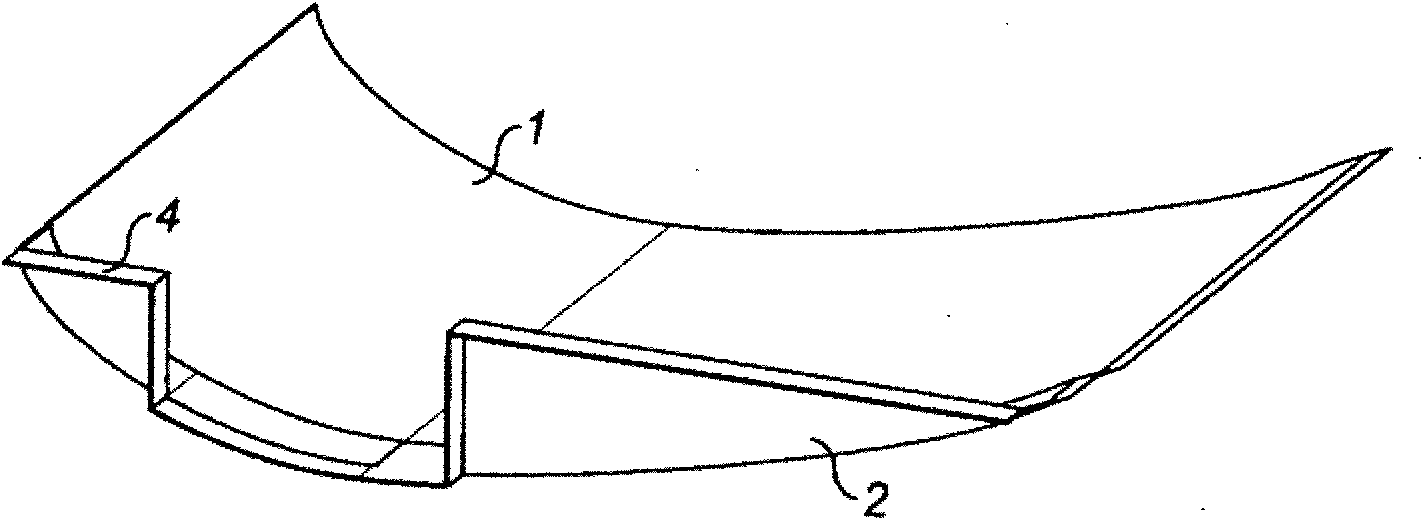

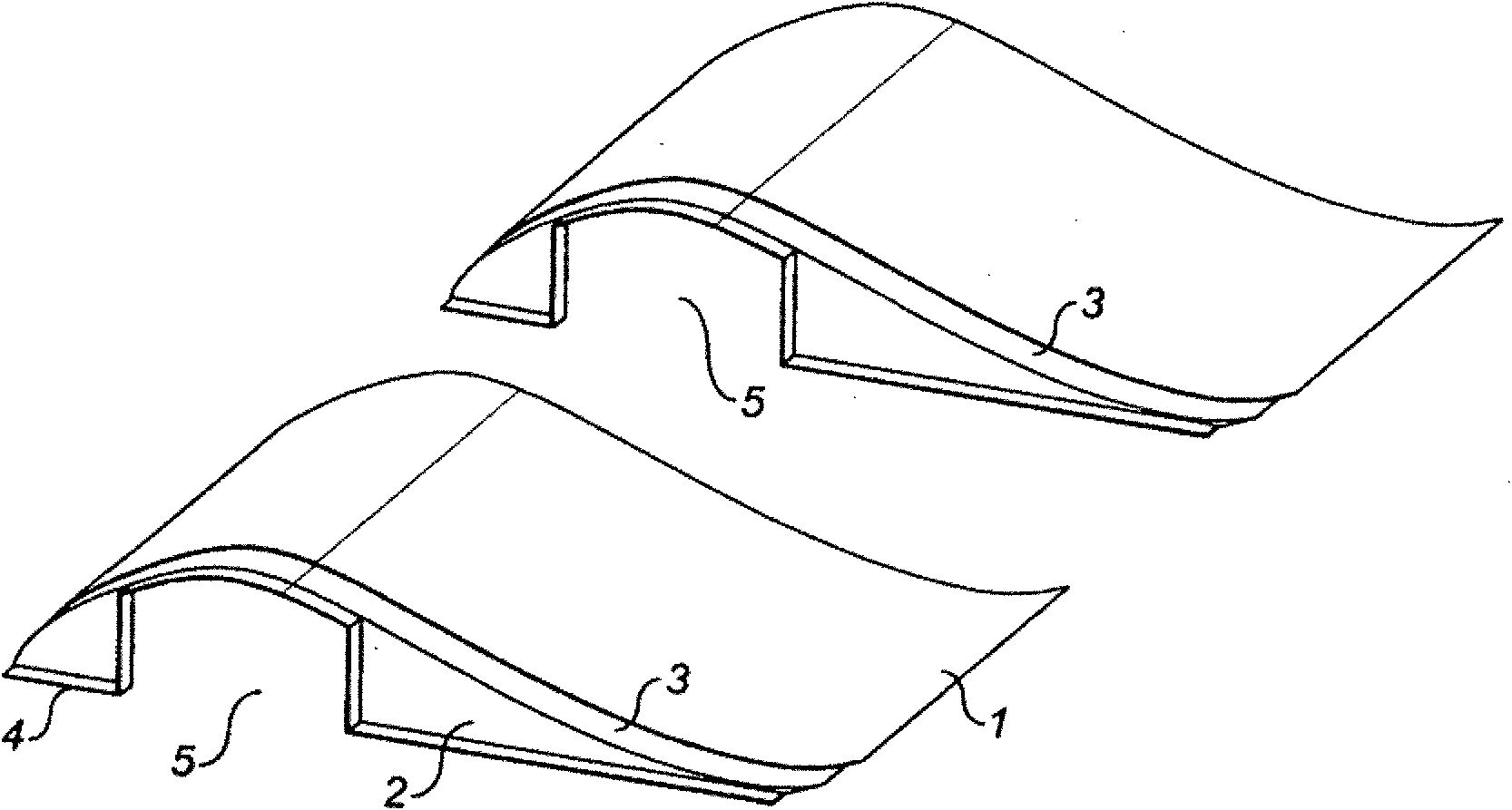

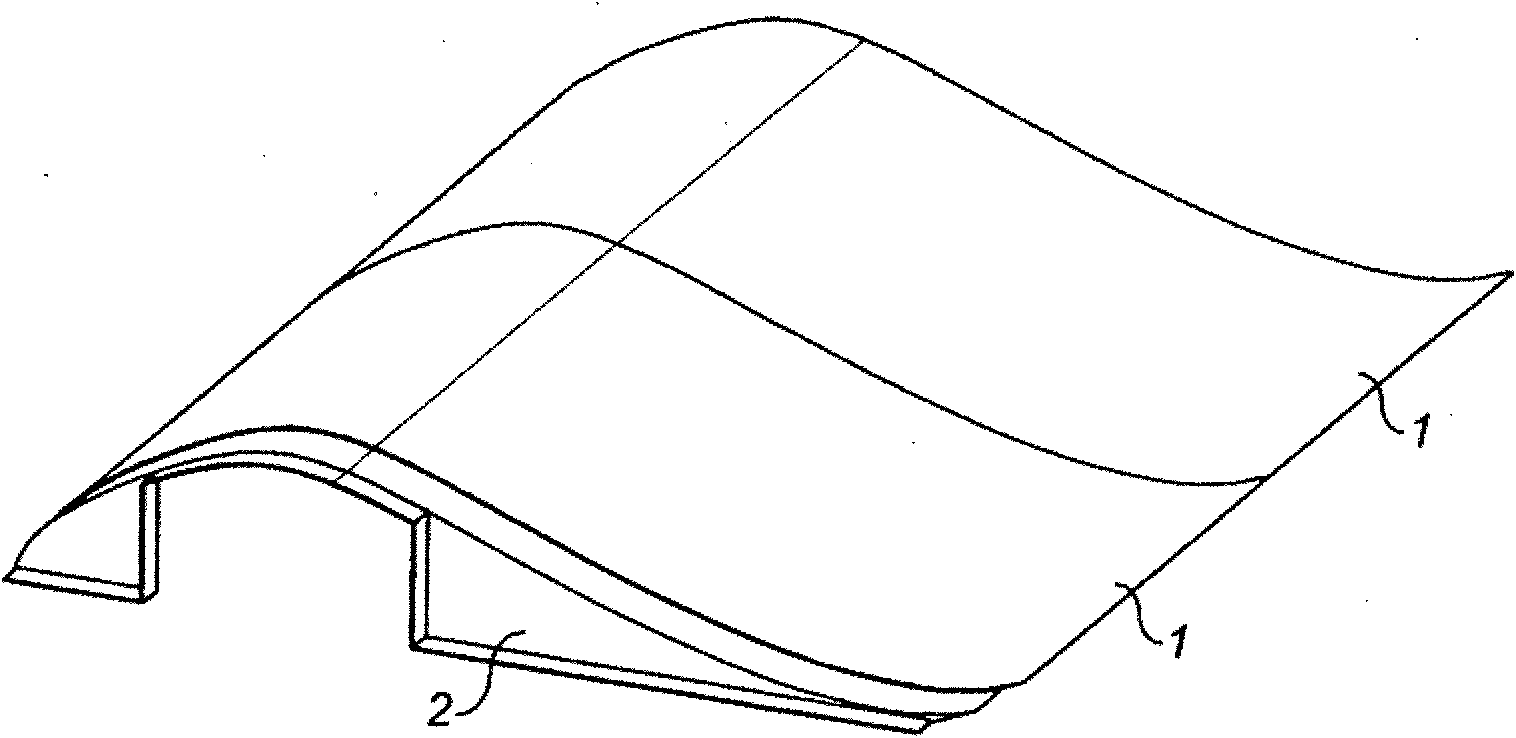

[0027] The skin panel consists of a skin part 1 and a partition 2 . The skin part 1 has an aerodynamic profile shape corresponding to a part of a half wind turbine blade. At the end closest to the tip of the final blade, the skin portion is provided with a recess 3 extending across the entire width of the blade and arranged to support an adjacent wall plate. The partitions 2 are positioned at the same end and extend across the entire width of the inner surface of the skin portion. A flange 4 extends across the inner surface of the bulkhead providing a contact surface. The flange 4 is provided with an opening 5 which fits around the spar described below.

[0028] Leading and trailing edge joints at Figure 4 , 4A and 4B are shown. Upper skin panel 10 and lower skin panel 11 are in as Figure 4A shown in the leading edge joint 12 and as Figure 4B Connect at trailing edge joint 13 shown in . At the leading edge, the upper skin panel 10 has a recess 14 which receives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com