Method for flexibly connecting canvas for splicing between adjacent copper alloy oblique square nets

A copper alloy and soft connection technology, which is applied in application, fish farming, climate change adaptation, etc., can solve the problem of difficulty in the widespread use of metal orthorhombic nets, poor safety and fishery adaptability, and escape of cultured fish in cages, etc. problems, to achieve the effect of avoiding the occurrence of fish escaping accidents, saving breeding costs, and reasonable and reliable operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

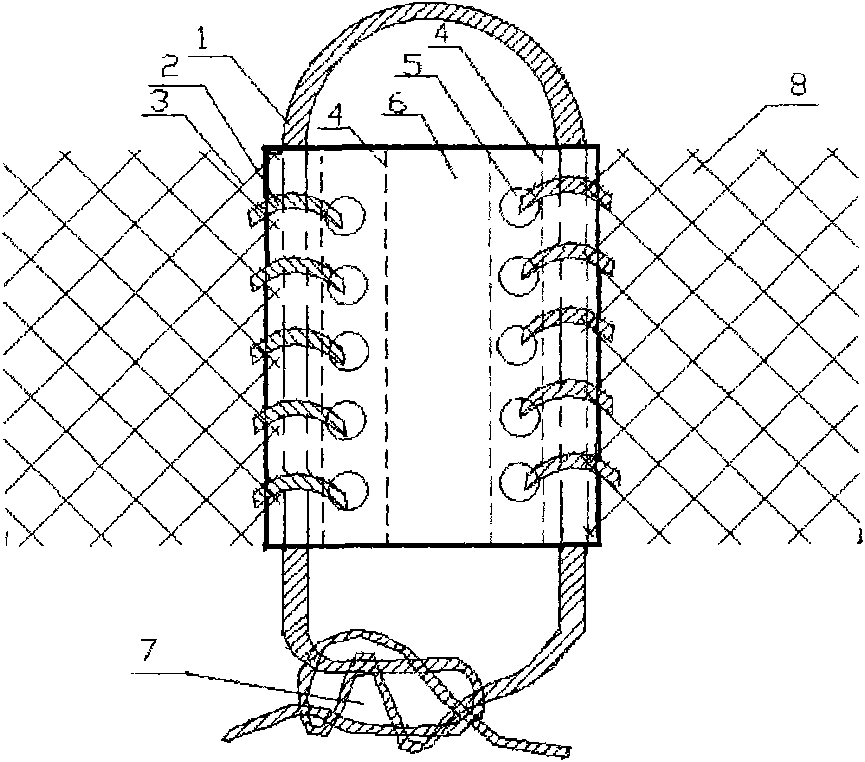

[0008] The following is an example of the splicing between the copper alloy orthorhombic nets of 25mm in the foot length of the mesh (the splicing length between the adjacent two copper alloy orthorhombic nets of the net clothing system is 1.0m), and the most practical method of implementing the present invention is illustrated in conjunction with the accompanying drawings good way:

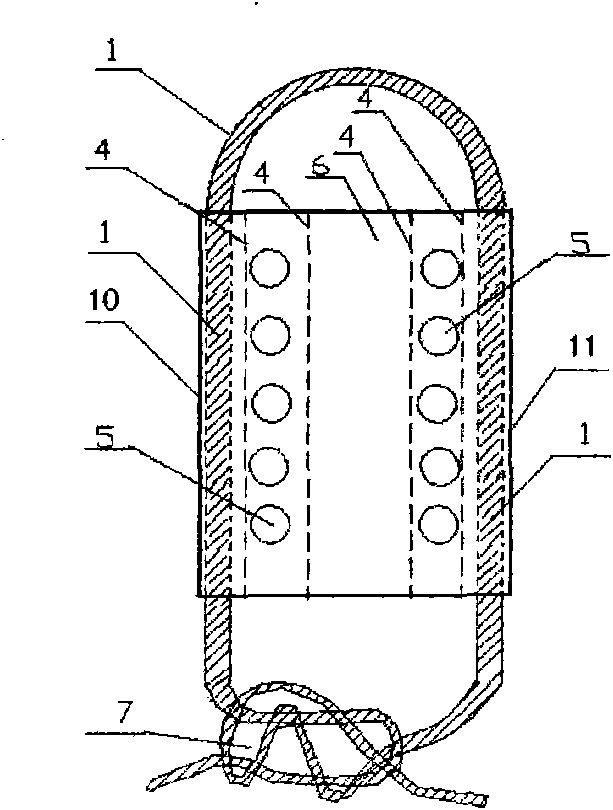

[0009] figure 1 1 in it represents the rope used for making canvas soft connectors, figure 1 4 in the figure represents the suture thread used for making canvas soft connectors, figure 1 5 in the figure represents eye rings for making canvas soft connectors, figure 1 The 6 in it represents the nylon canvas tube used for making canvas soft connectors, figure 1 The 7 in the figure represents the double dead knot made by the two ends of the rope used for making the canvas soft connector, figure 1 10 in the figure represents the left side of the nylon canvas tube used for making canvas soft conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com