Method for constructing continuous U-shaped beams

A construction method, U-shaped technology, applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of long construction period, large bending moment, and low utilization rate of beam body sections, so as to save consumption and reduce span Medium bending moment, considerable economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

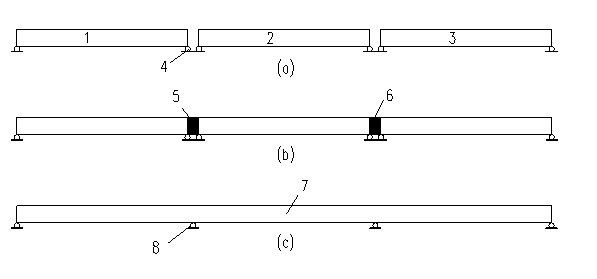

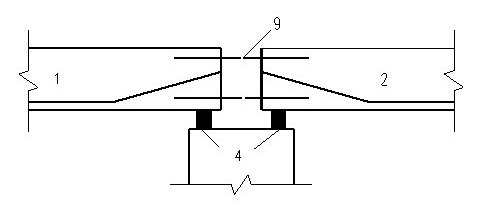

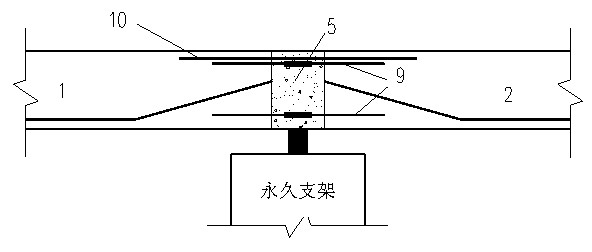

[0011] Below in conjunction with the accompanying drawings, the continuous beam construction method of the present invention is described in detail, and the steps of the construction method of the present invention are roughly the following 3 steps:

[0012] 1. The simply supported U-shaped beams 1, 2 and 3 required for maintenance are first poured in the beam factory, and the first-stage steel bundle 9 is stretched to meet the force requirements of the beam body during the simple support period and the hoisting process, and then transported to the construction site after reaching the installation requirements. The whole is hoisted in place (temporary support), and the prefabricated beam section is pre-installed on the temporary support 4 according to the simply supported beam to form the simply supported beam section ( figure 1 Take three spans as an example to form simply supported beams 1, 2, 3), and reserve a joint between the U-shaped beam and the U-shaped beam, the width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com