Serially connected casing pipe heat exchange device

A heat exchange device and heat exchanger technology, which is applied to heat exchanger sealing devices, heat exchange equipment, heat exchanger types, etc., can solve the problems of complicated pipelines, complex processing technology, low reliability, etc., and reduce manufacturing costs. , the effect of simplifying the processing process, improving reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

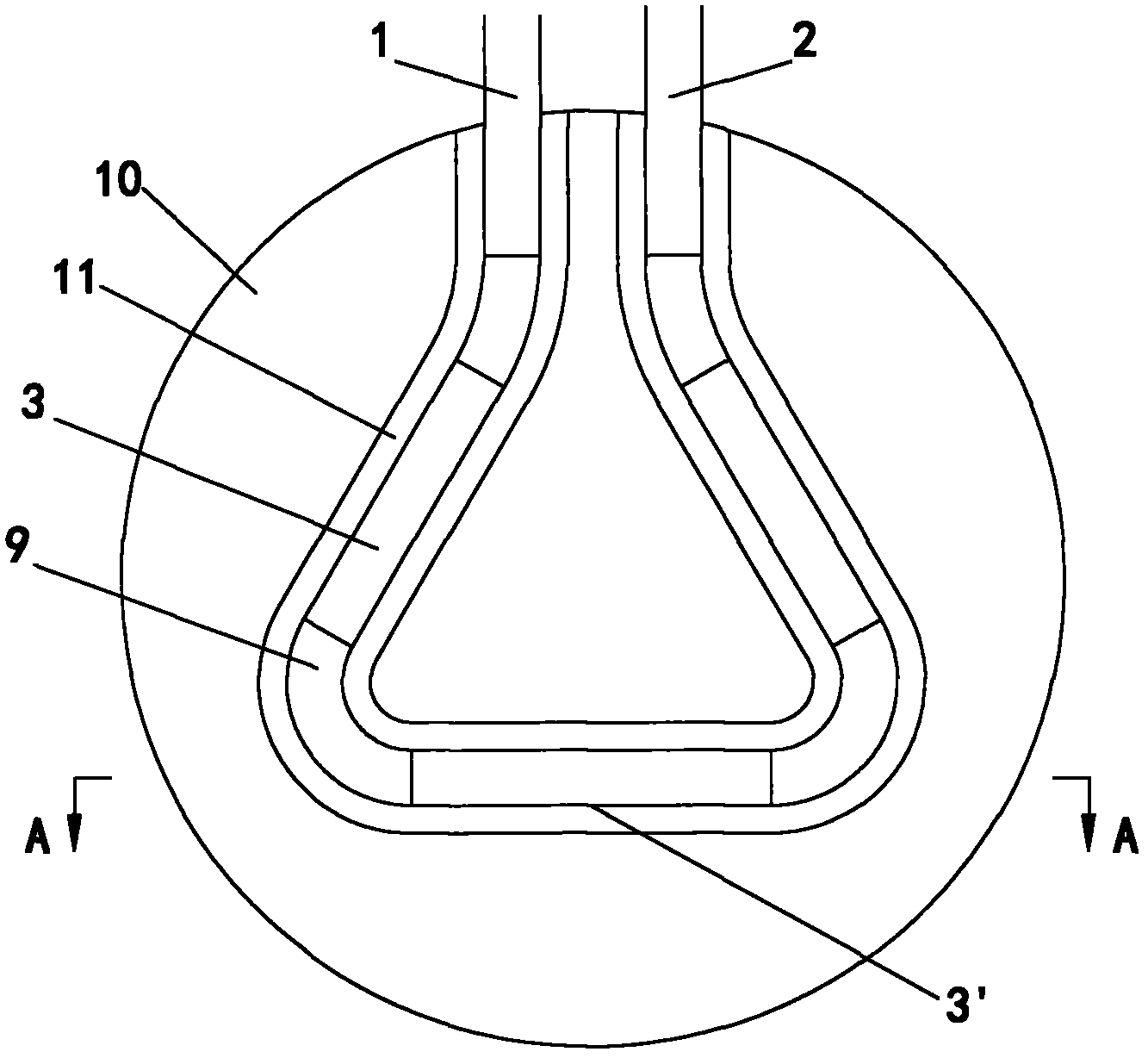

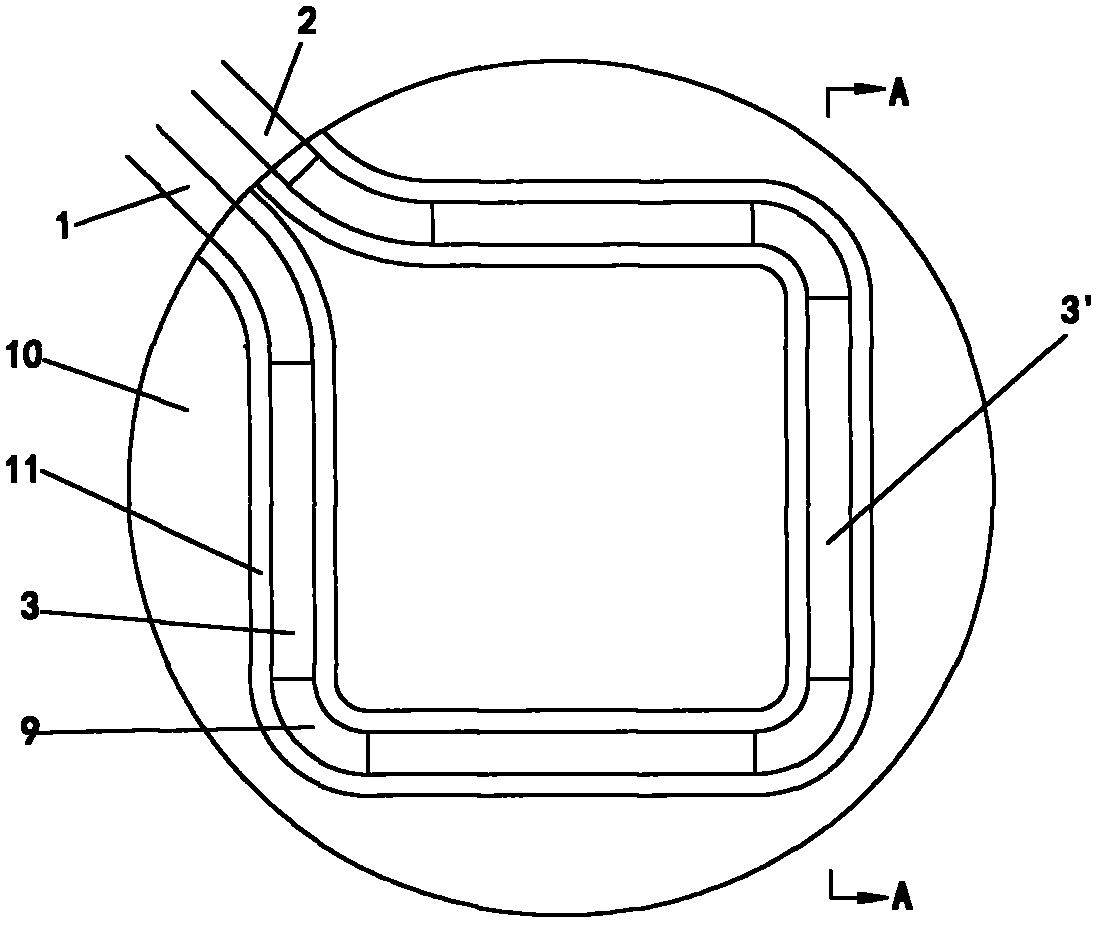

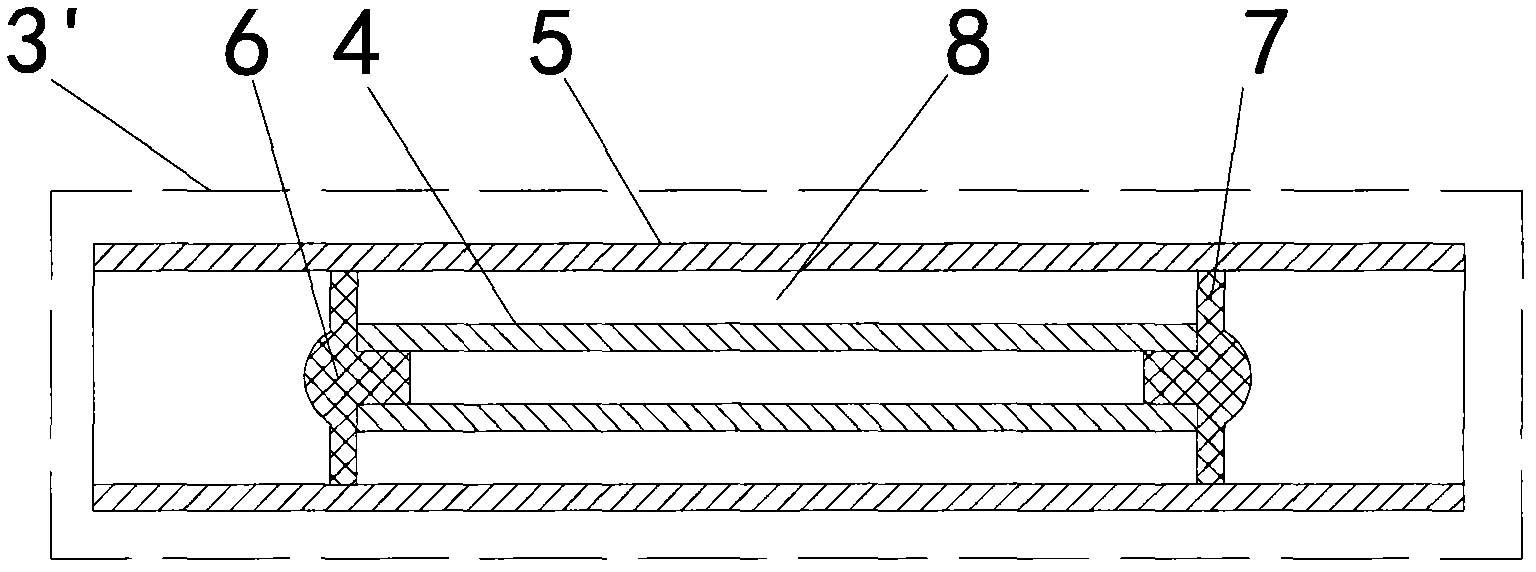

[0013] In the figure, in consideration of household tap water pressure requirements and floor space issues, the casing heat exchanger (3) of this scheme is formed by connecting three or four double-pipe heat exchangers (3)' with connecting pipes (9). The two ends are respectively externally connected to the water inlet port (1) and the water outlet port (2) through connecting pipes. Among them, the double-tube heat exchanger (3)' has selected two thin-walled stainless steel tubes with a wall thickness between 0.4-1.5 mm, wherein the inner tube (4) has an outer diameter of 16-27 mm, and the outer tube (4) has an inner diameter of 19-32mm, both ends of the inner tube (4) are sealed with seals (6) and built into the outer tube (5). In order to avoid affecting the installation performance of the double-tube heat exchanger (3)', the inner tube (4) The length of the outer tube (5) should not be greater than the length of the outer tube (5). The inner tube (4) is coaxially fixed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com