Lens module gluing location device

A lens module and positioning device technology, applied in installation, optics, instruments, etc., can solve problems such as affecting assembly yield, overflowing glue, dispensing misalignment, etc., and achieve the effect of saving dispensing time and accurate dispensing positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

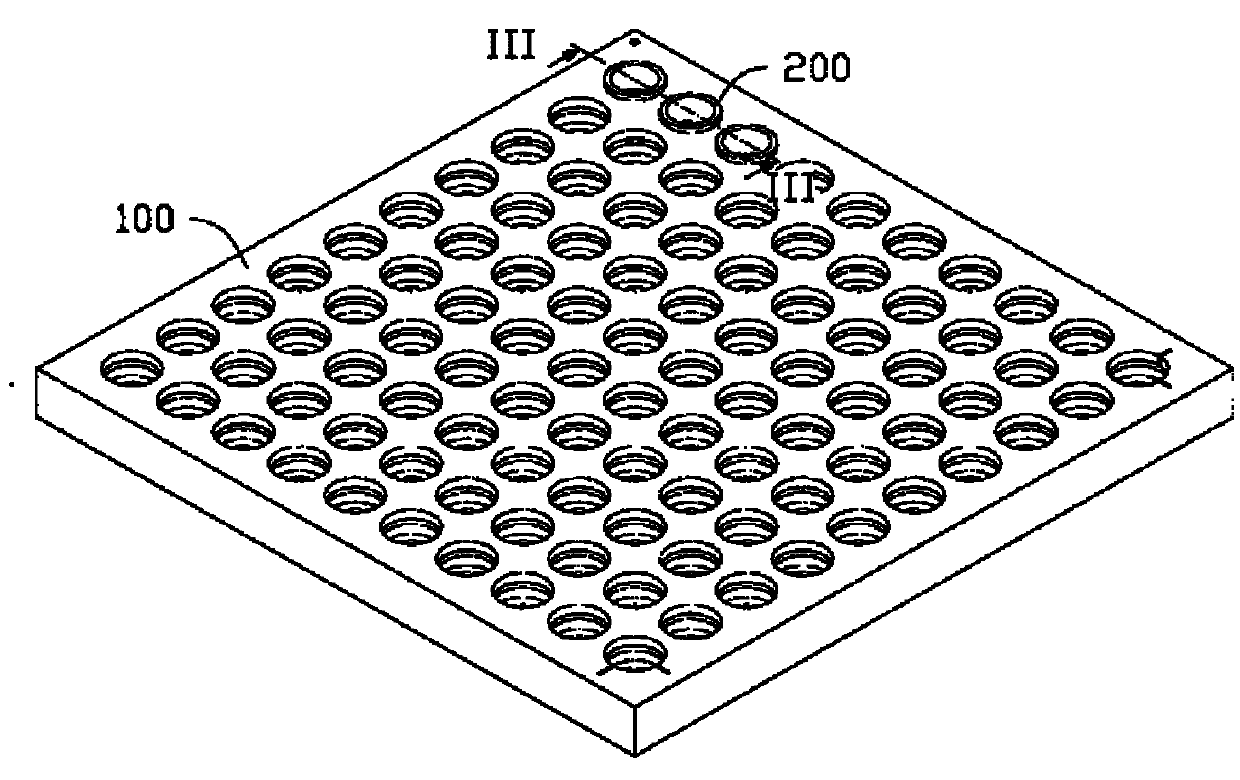

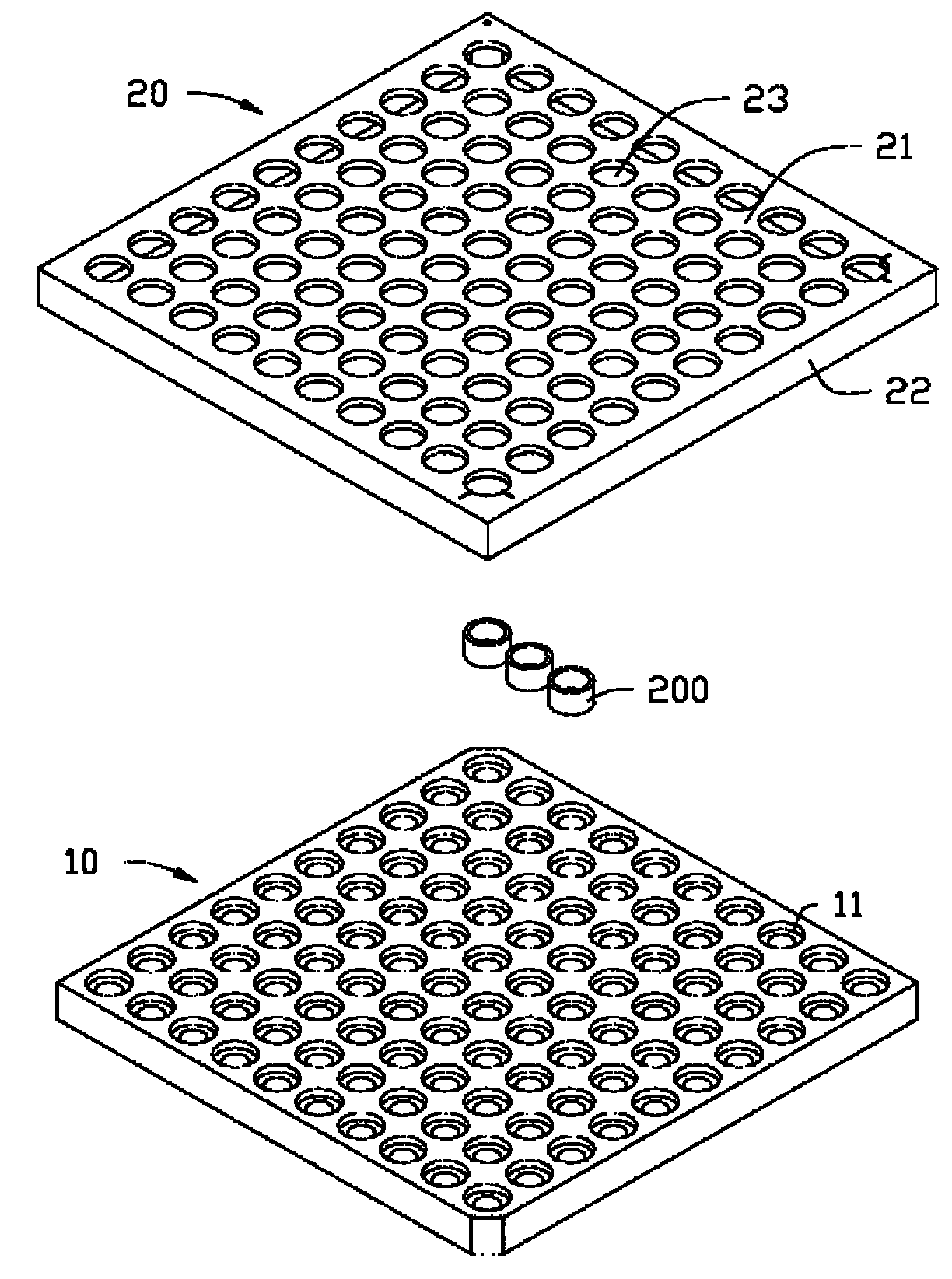

[0015] Such as figure 1 and figure 2 Shown is a preferred embodiment of the dispensing positioning device 100 of the present invention. The glue dispensing positioning device 100 is used to precisely position several lens modules 200, and only a part of the lens modules 200 are shown in the figure. The lens module 200 is in the shape of a cylinder, and optical elements to be dispensed are arranged inside it. The dispensing positioning device 100 includes a tray 10 and a cover 20 disposed on the tray 10 .

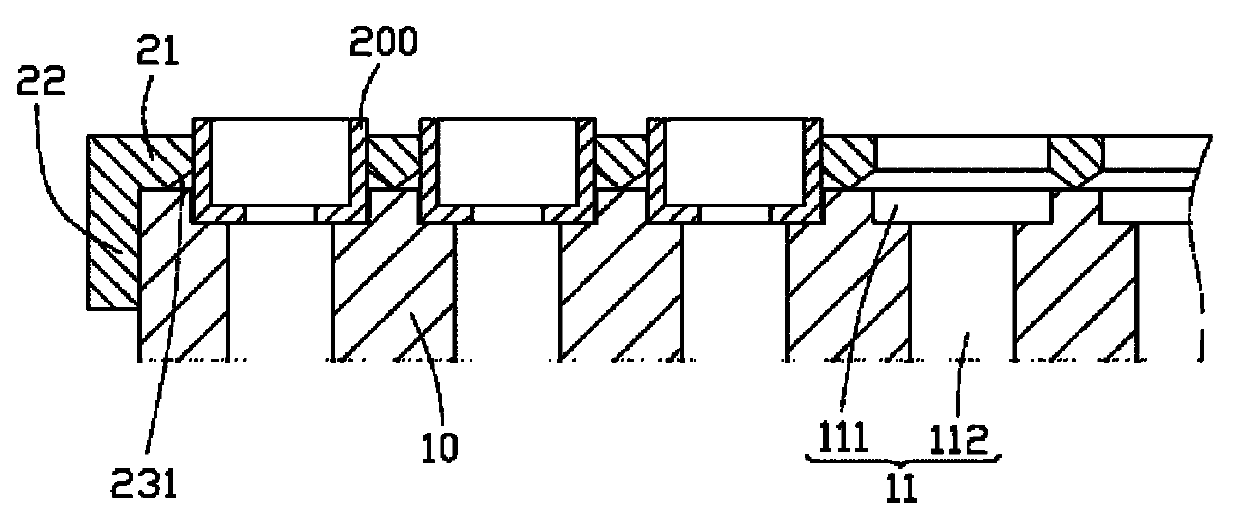

[0016] Please also refer to image 3 , the tray 10 is in the shape of a square, and a plurality of receiving holes 11 are arranged on it for carrying the lens module 200 . Each receiving hole 11 is stepped and runs through the tray 10, including a cylindrical upper hole 111 and a cylindrical lower hole 112, and the diameter of the lower hole 112 is smaller than the diameter of the upper hole 111, that is, the size of the upper hole 111 larger than the size of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com